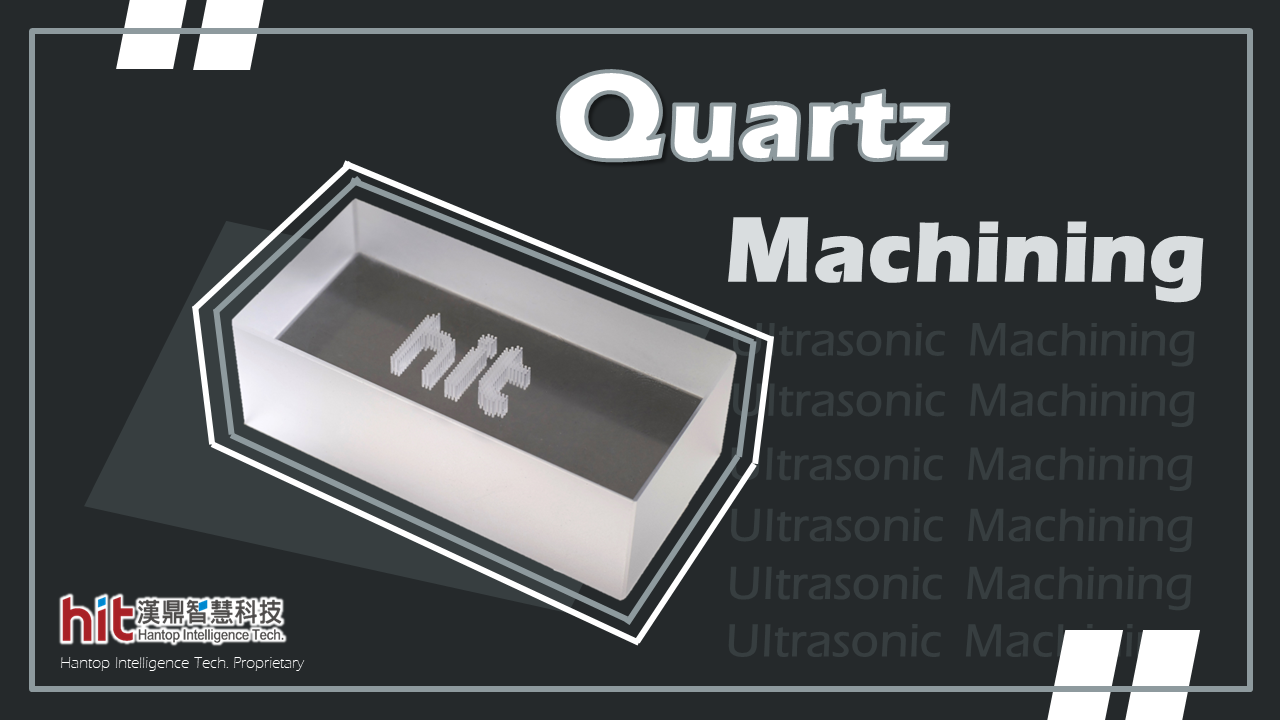

What Does HIT Ultrasonic Machining Bring to Quartz Machining?

HIT’s ultrasonic-assisted machining technology provides the superimposition of the tool rotation with a high-frequency oscillation in longitudinal direction, generating over 20,000 times of micro-vibration per second. The mechanism helps reduce cutting forces and facilitates chip removal process.

The reduction in cutting forces not only decreases frictions between tools and workpieces, but also allows feed rates to be increased. This greatly improves the quality of workpieces and the stability of tool life, and saves quite an amount of processing time.

Facilitating chip removal process diminishes frictions on both tools and workpieces caused by excessive amount of chips. HIT’s ultrasonic high-frequency micro-vibration allows chips to break easily and lessens the occurrences of entangled chips. This also displays a great benefit to both the quality of workpieces and the stability of tool life.

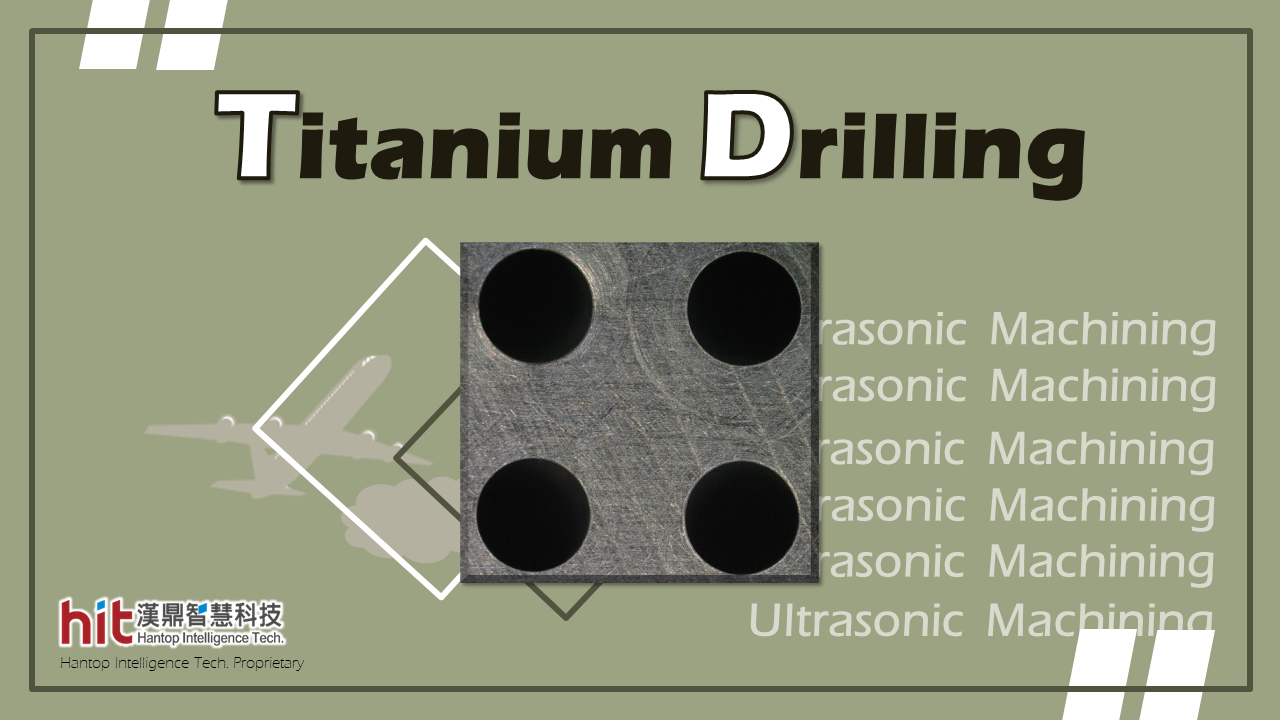

The technology specializes in micro-drilling and deep hole drilling hard and brittle advanced materials, including technical ceramics, quartz glass, super alloys, etc. The high-frequency micro-vibration displays the ability to control the cutting force in stable manner, decreasing the possibilities of severe subsurface damage. Offering a better way to improve the machining process by effectively enhancing machining efficiency, stabilizing the tool life, and bettering the quality of workpieces.

HIT’s ultrasonic-assisted machining technology provides the superimposition of the tool rotation with a high-frequency oscillation in longitudinal direction, generating over 20,000 times of micro-vibration per second. The mechanism helps reduce cutting forces and facilitates chip removal process.

The reduction in cutting forces not only decreases frictions between tools and workpieces, but also allows feed rates to be increased. This greatly improves the quality of workpieces and the stability of tool life, and saves quite an amount of processing time.

Facilitating chip removal process diminishes frictions on both tools and workpieces caused by excessive amount of chips. HIT’s ultrasonic high-frequency micro-vibration allows chips to break easily and lessens the occurrences of entangled chips. This also displays a great benefit to both the quality of workpieces and the stability of tool life.

The technology specializes in micro-drilling and deep hole drilling hard and brittle advanced materials, including technical ceramics, quartz glass, super alloys, etc. The high-frequency micro-vibration displays the ability to control the cutting force in stable manner, decreasing the possibilities of severe subsurface damage. Offering a better way to improve the machining process by effectively enhancing machining efficiency, stabilizing the tool life, and bettering the quality of workpieces.

Hantop Intelligence Technology

Brand Name:

Hantop Intelligence Technology

Booth Number :

P1232

Contact Information :

- www.hit-tw.com

- +886-4-22850838

- +886-4-22850836

- Room 921, Applied Science & Tech. Building, No. 145 Xingda Road, South District, Taichung City 402, Taiwan