We have three production sites located in Taiwan and China. Two are located in Taoyuan City, Taiwan. The third factory is in Kunshan City, Jiangsu Province. The total manufacturing area covers over 39,669 square meters. The company has 400 employees and a capital of NT$ 480 million.

Over four decades we have accumulated a vast experience in the design and production of mechanical devices, producing well-received customized cams, automatic tool changers, and intermittent indexing drives for automation applications. Our cams, ATCs, and indexers currently have market shares of 75%.

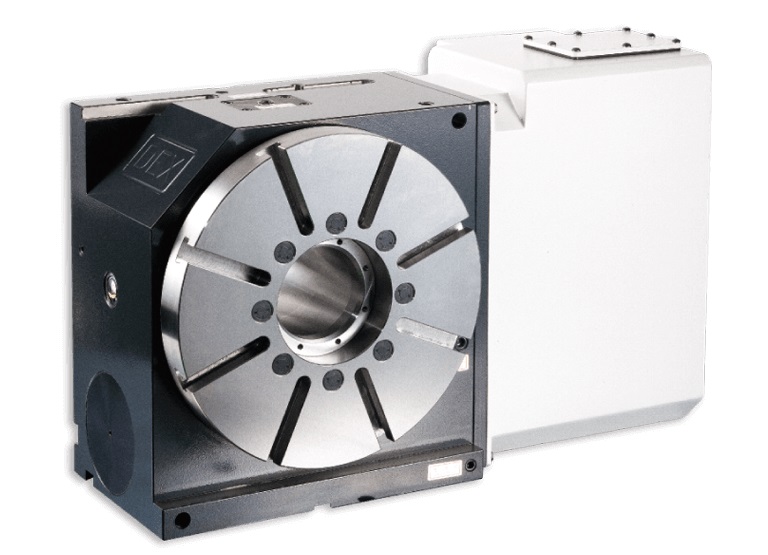

DEX’s newly introduced 4th and 5th axis rotary tables were developed by our excellent and experienced engineering team. We keep rigid standards throughout all the manufacturing processes and offer satisfactory after-sales services for customers all over the world. The positioning accuracy, structural rigidity, and lifespan of our products are as good as our competitors’ products from Europe, Japan, and the US. This is why so many manufacturers choose DEX products.

Rolling contact between the roller and the cam, no positive reversal backlash problem, greatly improving the ultra-precision characteristics of the roller cam, reducing the defect rate and improving the quality, which is a breakthrough for precision machining technology.

Roller cam type turret conducts in rolling mode, reduces wear, high transmission efficiency, high speed operation, and conduction efficiency of over 90%.

Due to low wear and low aging, it can maintain initial accuracy for a long time.

Even at high speeds, reduce friction, reduce thermal displacement, improve quality stability, and reduce non-performing rates.

When the brake is positioned, the disc surface will not sway back and forth, and the positioning brake will remain within 2µm, which can highly demonstrate the precision machining quality.

Conduction efficiency 90~95%

Over four decades we have accumulated a vast experience in the design and production of mechanical devices, producing well-received customized cams, automatic tool changers, and intermittent indexing drives for automation applications. Our cams, ATCs, and indexers currently have market shares of 75%.

DEX’s newly introduced 4th and 5th axis rotary tables were developed by our excellent and experienced engineering team. We keep rigid standards throughout all the manufacturing processes and offer satisfactory after-sales services for customers all over the world. The positioning accuracy, structural rigidity, and lifespan of our products are as good as our competitors’ products from Europe, Japan, and the US. This is why so many manufacturers choose DEX products.

Rolling contact between the roller and the cam, no positive reversal backlash problem, greatly improving the ultra-precision characteristics of the roller cam, reducing the defect rate and improving the quality, which is a breakthrough for precision machining technology.

Roller cam type turret conducts in rolling mode, reduces wear, high transmission efficiency, high speed operation, and conduction efficiency of over 90%.

Due to low wear and low aging, it can maintain initial accuracy for a long time.

Even at high speeds, reduce friction, reduce thermal displacement, improve quality stability, and reduce non-performing rates.

When the brake is positioned, the disc surface will not sway back and forth, and the positioning brake will remain within 2µm, which can highly demonstrate the precision machining quality.

Conduction efficiency 90~95%

TE SHIN CAM CO., LTD

Brand Name:

DEX

Booth Number :

N0507

Contact Information :

- www.teshin.com.tw

- +886-3-3493596

- +886-3-3493600

- No. 88, Chajuan 1st, Gueishan Dist., Taoyuan City 333025, Taiwan