Theme

Digital Transformation

Green Transformation

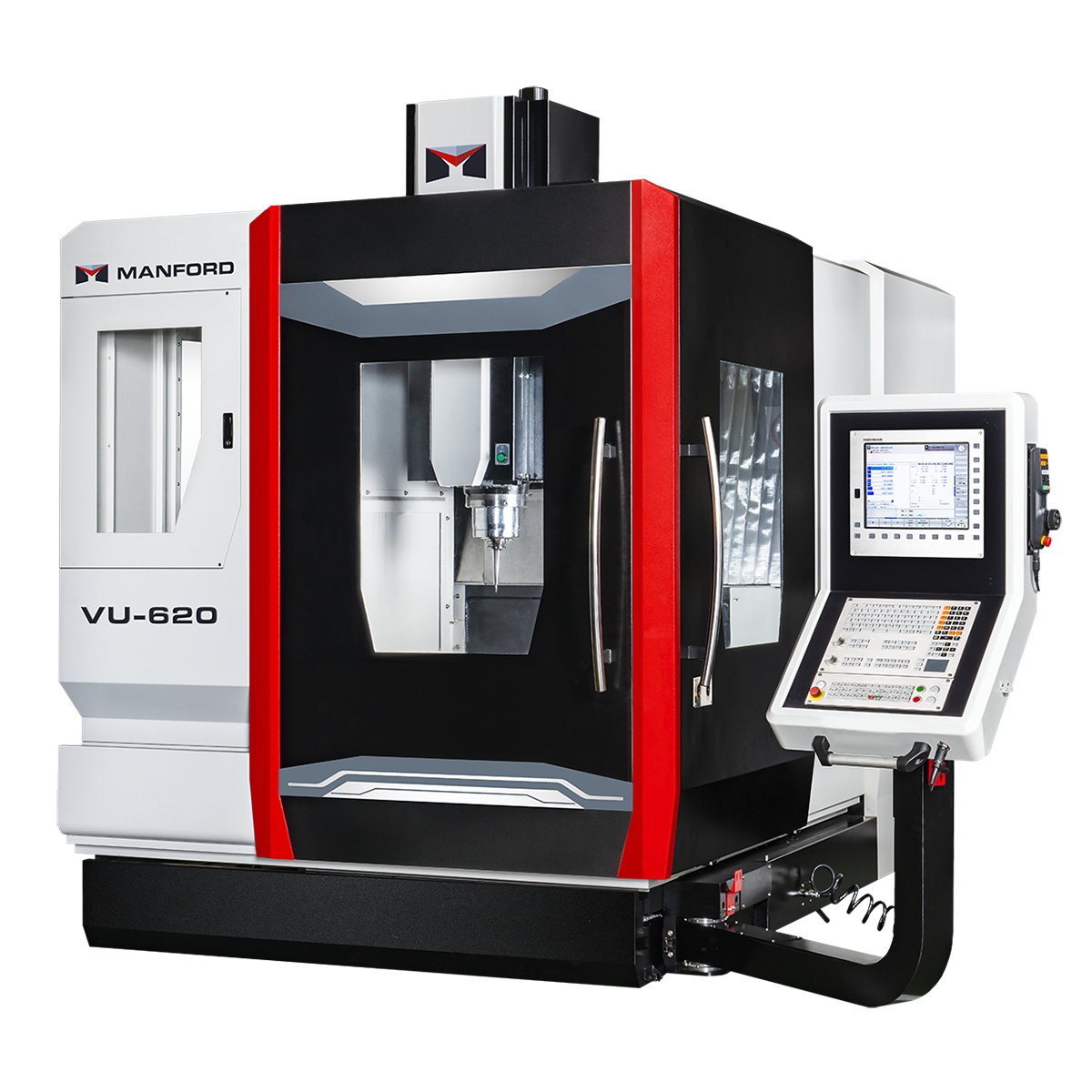

MANFORD MACHINERY CO., LTD.

Product Description :

Turnkey solution of VU-620 product line enables Manford to process and optimize parts efficiently, enhance productivity and accuracy. VU-620 adopts low-pollution components and complies with eco-friendly regulations. Occupying compact floor dimensions is also one of the features of VU-620.

VU-620 offers high speed, high accuracy and more reliable quality. Twin doors design with wide open space is easy for loading workpiece. Movable column C-shape provides superior rigidity. Rotary table with one-piece iron casting provides excellent ductility and greater anti-vibration. Rotary table selection: standard worm gear, or double DD motor.

JEFFER MACHINERY CO., LTD.

Product Description :

This machine comes in a one-piece construction that has been heat-treated to achieve maximum rigidity. The rails are thermal treated and precisely ground to reach hardness of more than HRC 60˚. Furthermore, options are available to adopt rails of various lengths to meet different knife grinding requirements. The machine length can be customized for specific needs from 1,600 to 4,000mm. Rough and finish grinding wheels can be controlled manually and automatically. The minimum grinding wheel downfeed amount is 0.005mm and the spindle is equipped with an automatic cooling system which ensures excellent cooling effect. The SSG-8 employs an automatic lubrication system for smoother operation and longer service life.

SSG-8 Feature :

1. Knife tools movement type.

2. After grinding by coarse wheel and fine wheel, knife

tools can be sharp.

3. Force cooling system on motor shaft obtains better

cooling effect for the knives.

4. Grinding wheel lifting seat is used by ball bearing screw,

it can adjust up and down movement in precision.

5. Water splash guard and coolant tank are made of

stainless steel.

6. Grinding Capacity (Magnetic Chuck) LxW :

2500x200mm

FALCON MACHINE TOOLS CO., LTD.

Product Description :

Easy Setup, Flexible and Sealed for Grinding

The FVGC Series of vertical grinding machines is another prime example of Chevalier's position as the global leader in grinding technology. The series seamlessly increases efficiency and productivity for such industries as semiconductor, punch and aerospace, as well as other sectors for which these machines can be equipped. Workpieces in these fields primarily are a composite, single crystal silicon or brittle, along with other materials that present process challenges.

MING YANG MACHINERY CO., LTD.

Product Description :

This multi-tasking turning center is an advanced machine designed to process precision complex parts in one setup.

Power & Versatility: It has Double Spindles, a VDI/BMT 12 station Turret and a 2nd Y-Axis for back machining with 14 tools for a total capacity of up to 38 tools. This solution with superimposed cutting is a powerful combination of precision and two Y-axes for machining of complex workpieces with extremely fast cycle times.

Front Machining: BMT45 12-Stations, Up to 24 tools, 7.5/11 kW Spindle Power, 55 mm Through Hole.

Back Machining: Gang Tools Slide: 14 Tools, 3 Cross Live Tools, 3 Face Live Tools, 3 OD & 5 ID Tools.

SIEMENS LTD., TAICHUNG BRANCH OFFICE

Product Description :

The powerhouse in the compact CNC class

With its unique CNC performance, our SINUMERIK 828D control sets productivity benchmarks when it comes to milling and turning on standard machines as well as functions to simply automate grinding machines. With new SINAMICS drives and SIMOTICS motion control motors SINUMERIK 828D is now even more productive.