Theme

Digital Transformation

Green Transformation

Administration for Digital Industries, moda

Product Description :

AEAPLUS Smart Factory empowers you to create the ultimate production workflow!

Highlights include:

MES System: Intelligently manage production for enhanced efficiency!

B2B Solutions: Simplify supply chains, expedite order processing!

WMS System: Precise inventory management, cost-saving!

PSRA Assistant: Smart scheduling for automated production!

PDM Management: Optimize product data for improved performance!

QRM Quality Records: Elevate quality control, continual optimization!

BI Analytics: Data insights for informed decision-making!

RPA Automation: Streamline workflows, unleash manpower!

Irrespective of your factory's scale, our solutions deliver tangible benefits, aiding you in achieving more efficient and intelligent production processes.

PROTH INDUSTRIAL CO., LTD.

Product Description :

1.A : Auto-cross H : Hydraulic longitudinal R : Rapid up/down.

2.Overall architecture (horizontal module) : Overall structural design optimization /lightweight/stiffness strengthen.

3.Built-in spindle (15HP) with 20 inches grinding wheel.

4.Workpiece shape : flat grinding/step/plunge grinding.

5.Machine drive : Cross and vertical liner guide way, longitudinal double V guide way.

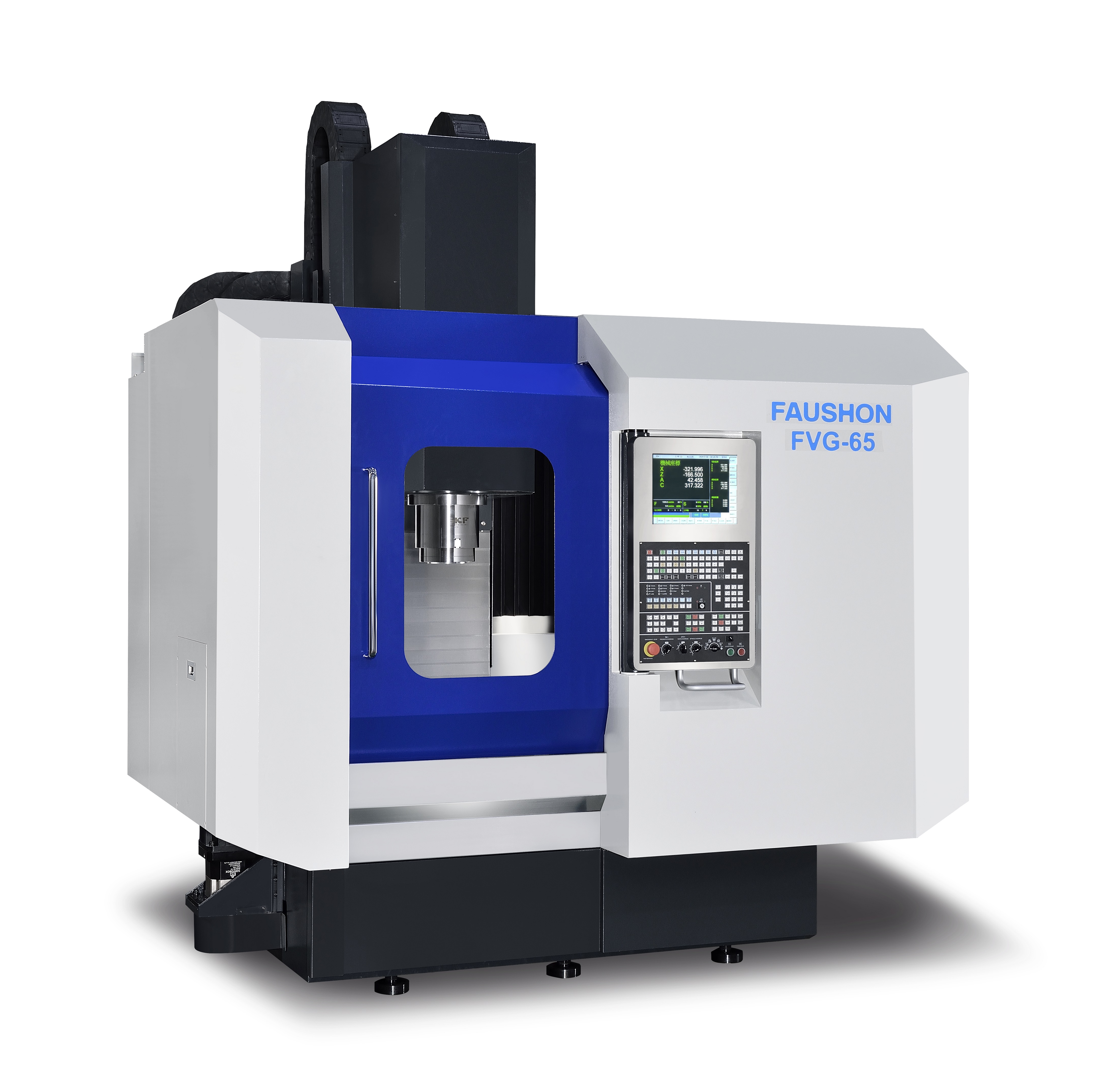

Fulson Industrial Co., Ltd

Product Description :

This model is the culmination of years of careful research and development by Faushon. It boasts a sturdy exterior and robust structure, with all operating handles and active control panels designed to be within the operator's optimal range and most comfortable operating position. This design adheres to ergonomic principles, providing you with higher work efficiency.

With our extensive experience in professional grinder manufacturing, we never compromise on accuracy. We can assure you that our machines offer high precision and reliability. We provide a variety of options and solutions to help address on-site challenges. Our machines are capable of multitasking and offer a high cost-performance ratio in terms of accuracy. The main structure design of the machine undergoes thorough finite element analysis and rigorous review of key components to achieve high precision and reliability.

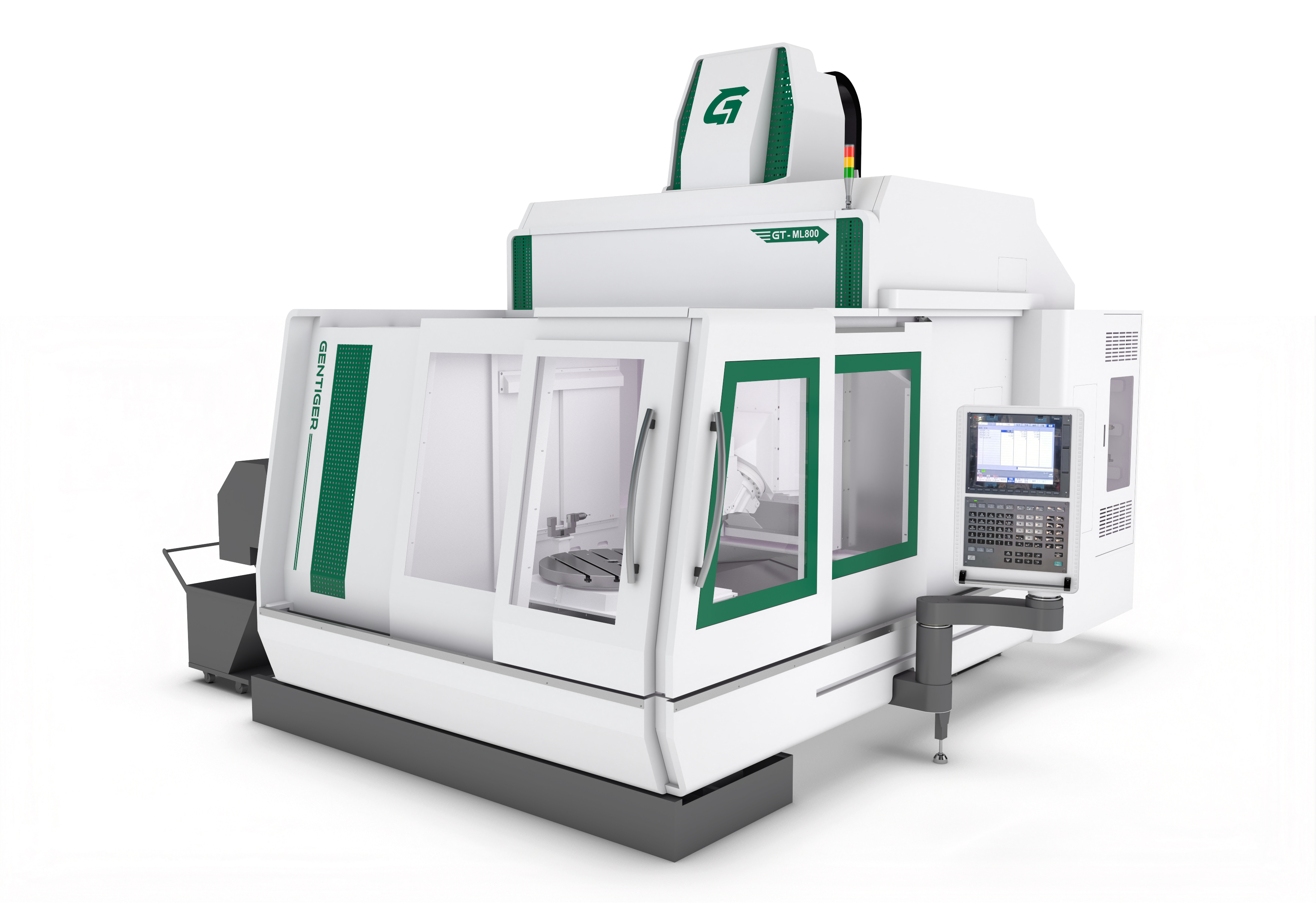

GENTIGER MACHINERY INDUSTRIAL CO., LTD.

Product Description :

• Closed-type double-column structure, it increases structure dramatically increases the structural rigidity of the machine and maintains extraordinary stability at all times.

• Roller-type linear guideway on three axes, it achieves high loading resistance, high rigidity, long service life, low thermal growth, and low noise.

• Three linear guideways on the Y axis, it provides more stable support for the spindle head, which contributes to upgraded stability in machining.

• The 45° vertical horizontal swiveling head is applicable for both vertical and horizontal machining, increasing flexibility in machining applications.

TORNG INDUSTRIAL CO., LTD.

Product Description :

* To provide cooling, lubrication and chips removal functions simultaneously.

* It's designed for machinability, machining speed and extend the tool life.

* To save machining time and reduce machining cost.

* To ensure high quality of machining and cutting performance.

R PLUS TECHNOLOGY CO., LTD

Product Description :

High performance: design life of more than 50 million times, super high stability

Low power consumption: 0.8/0.3W energy saving design , can be directly driven by PLC

Environmental : the novel inner row structure design

Easy to operate: convenient mode , eliminating the connection time

Provincial space: large flow design and compact