Theme

Digital Transformation

Green Transformation

ADLEE POWERTRONIC CO., LTD.

Product Description :

●Brushless DC Motor

1. Minimize EMI and maintenance free. Low noise.

2. Specialized design to have smooth shaft rotation and improved reliability.

3. Brushless DC motor is light weight and compact size, higher power density, higher torque density and higher efficiency than conventional motors.

4. The structure has an excellent behavior in energy saving during heavy load operation. The high efficiency range is much wider than other motors too.

5. Built-in NTC thermal resistor to prevent over heat problem.

●AC Driver

1. Available for all control interfaces, ex. RS 485, direct signal, PLC, HMI.

2. Convenient 220VAC driver power input from 60W. No more 24VDC power supply.

3. Built-in 24VDC mechanical brake control power.

4. Real motor speed display and signal output.

5. Panel control is always enabled with removed control or terminal control or RS485 control. Convenient for system set up or maintenance.

6. Excellent speed stability. Open loop and close loop speed control for selection.

7. With 0~5VDC, 0~10VDC and 4~20mA speed analog input.

8. Over current / heat / voltage, electric motor lock protection.

APEX PRECISION TECHNOLOGY CORP.

Product Description :

PVM-200 COMPACT CNC ENGRAVING & MILLING MACHINING CENTER

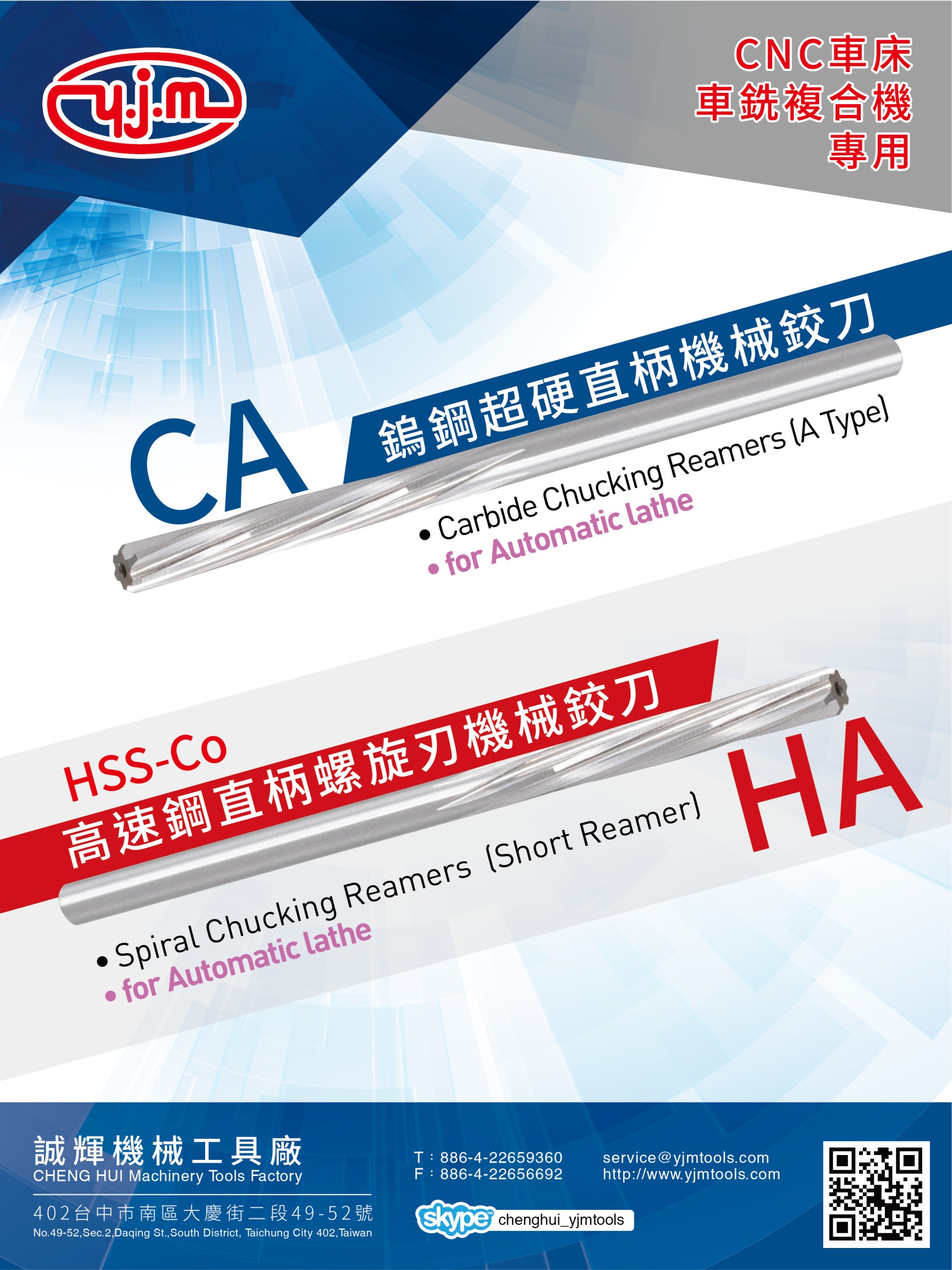

CHENG HUI MACHINERY TOOLS FACTORY

Product Description :

For Automatic lathe

Material: HSS-Co / Carbide

Tolerance:(+0~<+0.005)mm

ASMITH MANUFACTURING COMPANY

Product Description :

High precision, durability, stability electronic torque wrench, torque range of 0.1~1000 Nm, accuracy guaranteed ±1%, MIT, Japanese specifications wafer can use 20 years. Factory measured 100000 times to lock still keep high precision. Suitable for metal machine tool, controller & computer system, precision industry, high tech & electronic industry, quality assurance & manufacturing dep. |Tube Material:Medium carbon steel|Grip Material:ABS|Series: Standard Electronic Torque Wrenches, Mini Digital Torque Wrenches, Digital Torque Adapters, Open-ended Insert tools

JARNG YEONG ENTERPRISE CO., LTD.

Product Description :

1. This model combined the functions of turning and milling and can provide customers with more working conditions.

2. Optional C-axis for arbitrary angle spindle positioning and contour control

3. Optional Y-axis live tooling device and end live tooling device can be used for inner and outer diameter turning and milling.

4. Optional:Y-axis side milling device (4-shaft, ER-20), and the distance between each shaft reaches 55mm.

HONG JI PRECISION MACHINERY LTD.

Product Description :

Suitable for drilling center-hole on the round bars or shafts. The max. drilling length is 1500mm.

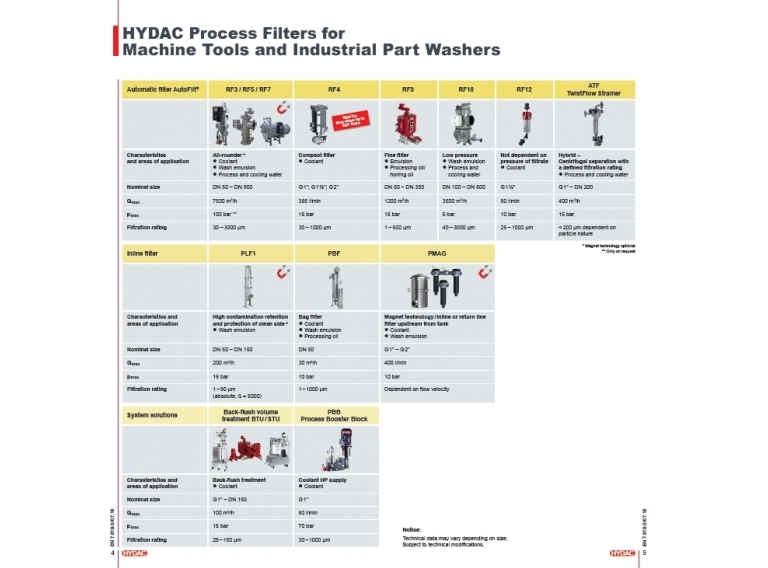

HYDAC TECHNOLOGY LTD.

Product Description :

HYDAC專精於系統過濾已累積50年以上的豐富應用經驗,近年來因應CTS中央出水系統<br />

日趨嚴苛的過濾精度要求、壓力自動調節及自動化生產的趨勢,更開發出一系列的自動逆洗<br />

過濾系統、無段比例控制調壓閥並整合成PBB中央出水增壓模組,可大幅縮小安裝空間及減化<br />

配管的複雜度。<br />

<br />

相關系統已經廣或世界知名汽車大廠採用,例如Ford, Chrysler, Fiat, IVECO, GEMA, Linamar, Teksid, Hyundai, KIA.<br />

工具機業者則有COMAU, ETXE-TAR, NTC...等公司採用。<br />

<br />

歡迎在TMTS展覽期間蒞臨HYDAC的攤位(4館德國區-4C145攤位)就近參觀指導。

TJR PRECISION TECHNOLOGY CO., LTD.

Product Description :

① Driven by D.D.M.

② No backlash, no wear

③ High-speed 200rpm

④ Oil cooling and auto self-locking system

⑤ Can be customized according to the requirement of the machine tool factory

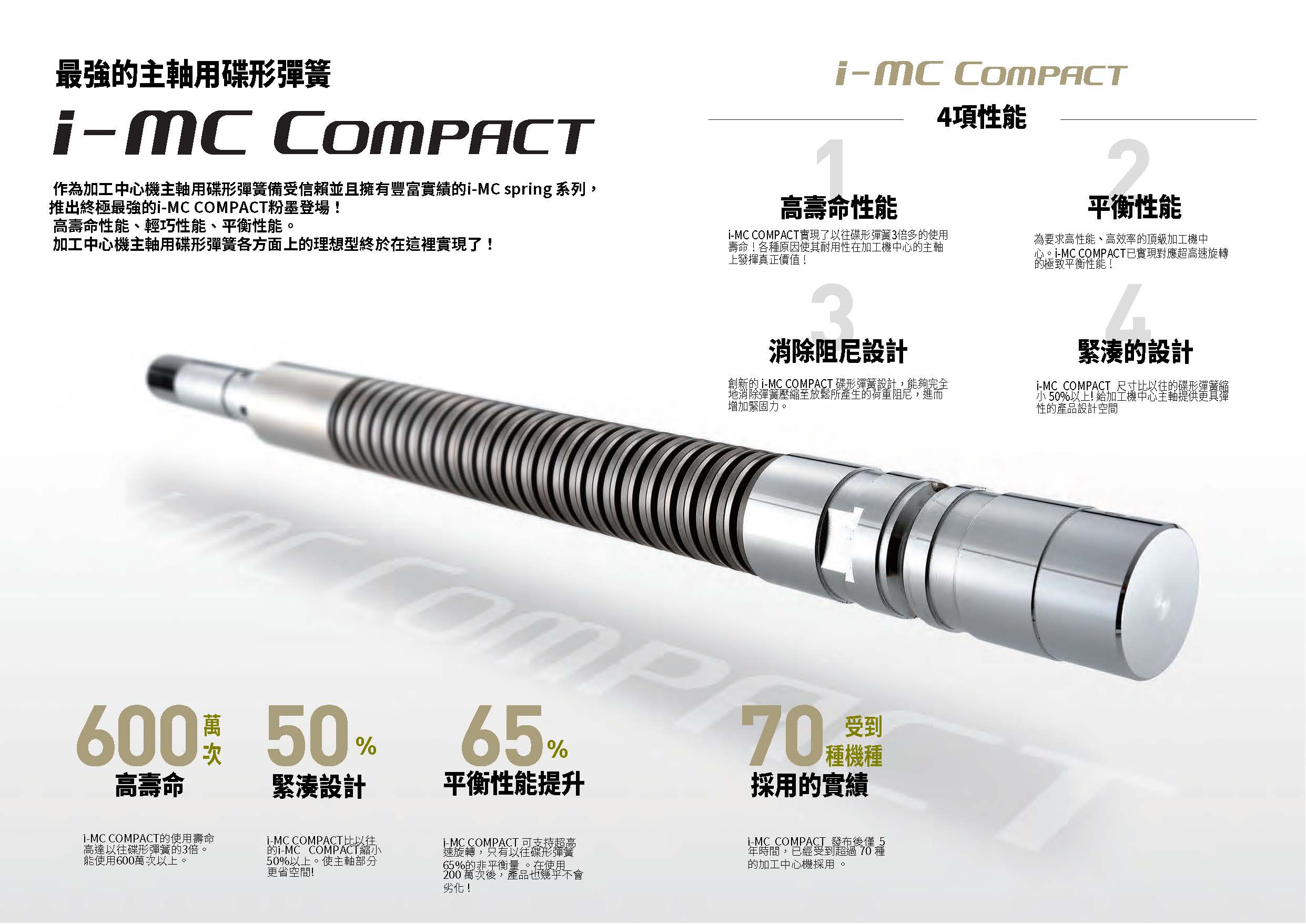

Tokai Spring industries, Inc.

Product Description :

i-MC spring series has established a strong trust and reputation as disc springs for the main spindle on machining centers among manufacturers. i-MC COMPACT is a new and innovative product of i-MC spring series.

Long-life performance, compact performance and balance performance.

In all of these aspects, this new product achieves the ideal form of disc springs for the main spindles on machining centers.

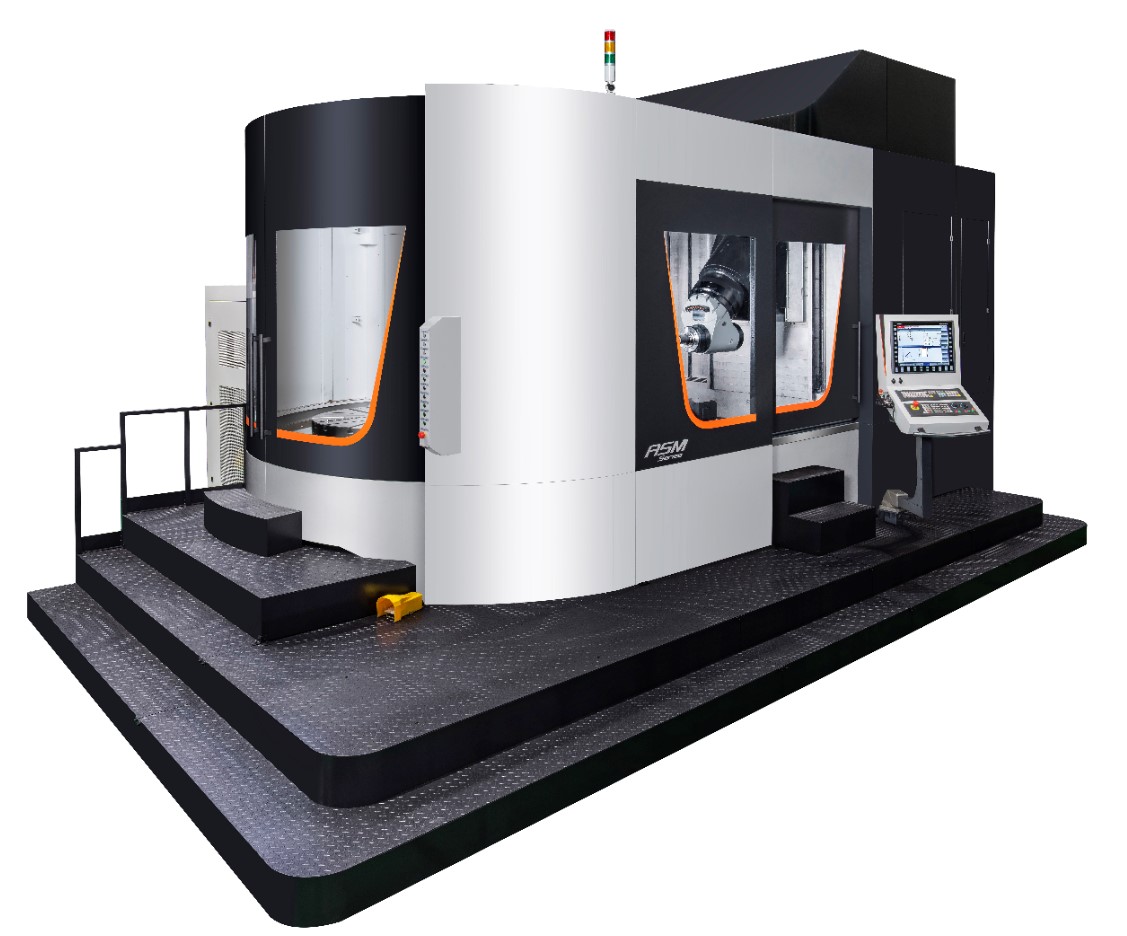

VISION WIDE TECH CO., LTD.

Product Description :

• ASM is the first 5-axis CNC turning and milling machining center of Vision Wide, and it is particularly designed for delicate cylindrical components machining featuring high acceleration, rapid feed-rate and synchronized axes machining, especially for aerospace components, tire molds, turbine blades and aluminum parts.

ASM accessorizes with 5-axis universal head and rotary shafts built-in D.D motor. Through topology analysis, ASM realizes the best distance between tool center point and B-axis transmission

• Positioning P0.006mm

• Repeatability Ps0.0055mm

• Spindle thermal compensation 0.02 mm

• Rapid Traverse 40m/min

• Acceleration 0.3G

• Cutting Feed rate 24 m/min