Theme

Digital Transformation

Green Transformation

REAL TERN INDUSTRIAL CO., LTD.

Product Description :

*RT Series cooler-Fixed tube model using

high efficient thread-rolling copper tube.

*Better heat capacity, smaller at size.

Applicable to machine tools cooling system.

*High precision and good quality on tube expanding system.

*Precise CNC machining equipment,

state-of-the-art technology.

LITZ HITECH CORP.

Product Description :

新一代的VB系列立式加工中心機,X/Y/Z軸採用全硬軌設計,主軸頭為齒輪傳動系統,實現了在低轉速輸出強大的切削力,搭配高剛性的主軸設計,滿足了重切削和高速切削的要求

ACCUTEX TECHNOLOGIES CO., LTD.

Product Description :

Linear Shaft Motor

Rapid servo control, enhancement of sensitivity in discharge gap control. Improving cutting speed up to 8~10%

1/1000 High Resolution Signal Process

High resolution in linear scale, achieve more smooth velocity control, and enhance the stability of position control, best match up contouring accuracy.

Stable Discharge Board (SD-Master)

Irregular Thickness Cutting

The AccuteX intelligent discharge unit is capable of dealing with the changing conditions in workpiece thickness and water flushing situations, featuring high cutting speed, and free from wire breaking problems.

PCD Cutting & Graphite Machining Power supply

The collapse of workpiece edge by wire cut can be controlled within minimum range along with high speed machining.

HABOR PRECISION INC.

Product Description :

Smart, energy-saving and high-accuracy DC inverter cooling machine can save more than 60% of electricity consumption through speed control and frequency conversion technology, and optimize the refrigerant system to reduce the amount of refrigerant used, which can also reduce the GWP value.

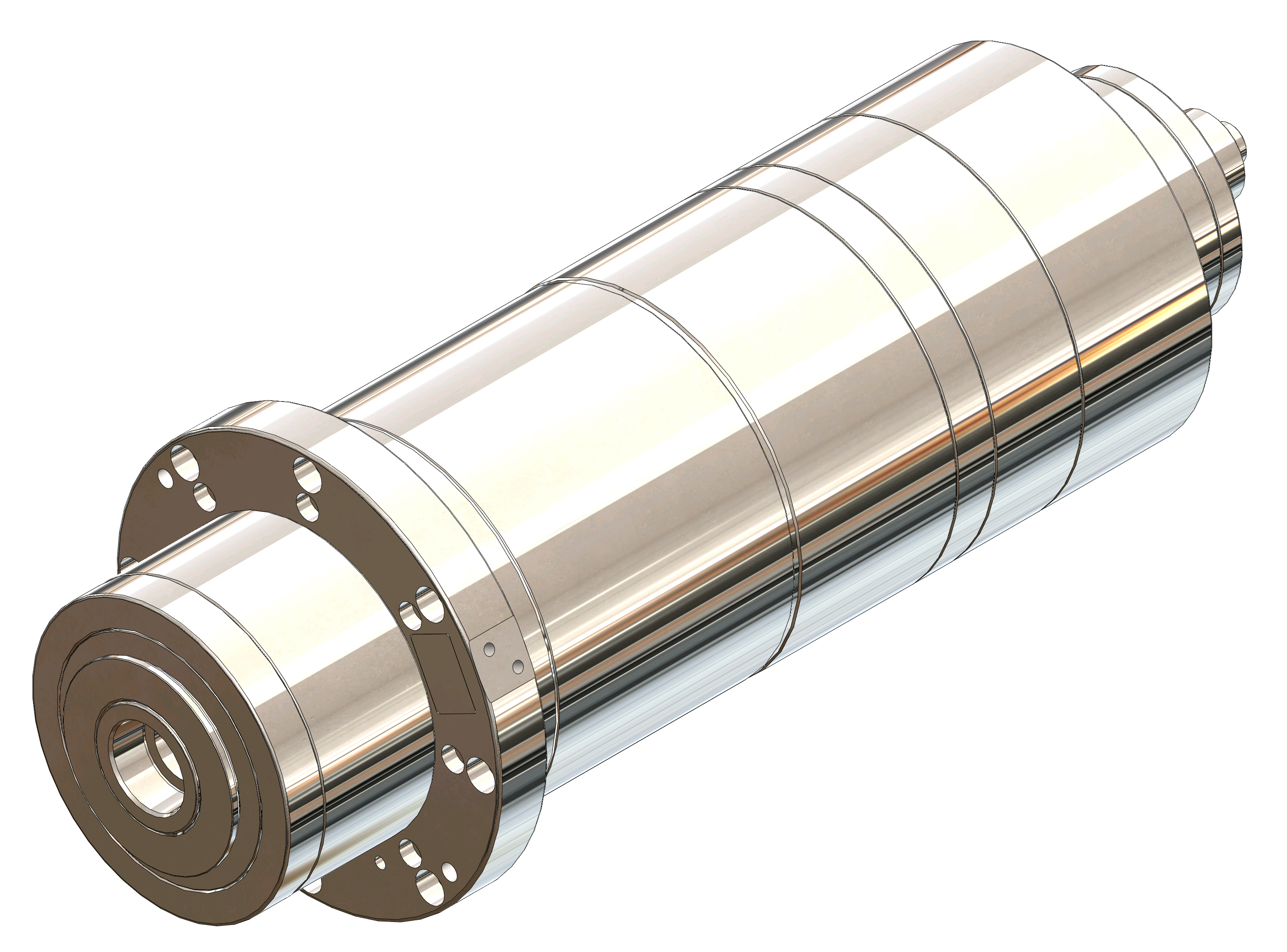

KENTURN NANO. TEC. CO., LTD.

Product Description :

Responds to the intelligent trends, Kenturn introduces the intelligent precision spindle for the high-speed CNC machining center. It emphasizes the thermal expansion displacement, temperature, and vibration sensing function, and can reach 30,000 rpm.

1. High speed 30,000RPM

2. Automatic Temperature Sensor

3. Thermal Expansion Sensor, Vibration Sensor

4. High dynamic rotary accuracy

CHIEN CHENS MACHINERY CO., LTD.

Product Description :

Specification

Table size: 1515 x 470 mm

Longitudinal travel: 1300 mm

Cross travel: 600 mm

A axis travel: 370 mm

Y slide way width: 720 mm

Z Slide high: MAX 700 mm

Z Slide way width: 420 mm

Spindle taper: NT#40(BT)

Spindle motor: 5HP / 4P

Spindle speed: 70~3600 RPM

Horizontal Spindle motor: 5HP / 4P

HorizontalSpindle speed: 70~3600 RPM

Feeding speed: 10~6000 mm/min

Ballscrew: Ø32 mm C5

Net weight: 3500 kgs

Ametek Taiwan Corp., Ltd.

Product Description :

Autocollimator:The autocollimator is used for measuring angle, straightness, flatness, squareness and parallelism.

MAT:The micro alignment telescope is used for alignment inspection and adjustment in machine tool and ship industries.

Talyvel:The Talyvel electronic level is used for measurement and adjustment, such as: straightness of machine tool guideway, flatness of granite platform.

Clinometer:Precision in angular measurement, checking and setting with 360° range.

Prism Checker:Automatic Prism/Polygon measurement system.

AUTOGRIP MACHINERY CO., LTD.

Product Description :

Whole stroke position montoring.Position setup by teach-in function.No more manual adjustion is required as the case of proximity switch.Save machine idle time .Compatible with PLC programing.

CHING HSYANG MACHINERY INDUSTRY CO., LTD

Product Description :

1. Stable construction, strong rigidity, low vibration and high cutting

accuracy.

2. Floating feeding method makes aluminum extrusion or material with a

little curve feed easily.

3. Extraordinary horsepower design. Horsepower can be adjusted

according to the demand of saw blades. It cuts fast and has great

productivity.

4. Two saw blade lubricating devices for powerful spray cooling and auto

cooling via cooling liquid.

5. Electronic saw blade protection device and automatic saw blade

stopping device ensure operational safety and the smoothness of the

sawed faces.

6. Patent, After cutting, separating work piece before cutting tool moves

backward, machined surface will be shiny without tooling trace, the life

of saw blade is long.

7.Digit display allows for easy, accurate and fast length adjustment.

8. Applicable for sawing and cutting aluminum, aluminum alloy, brass

alloy, brass and plastic.

9. Control knob provides easy central control and operation.

10. Automatic material-absence sensing and stopping device.

11. Can be equipped with a sawdust collector for clean and convenient

sawdust collection.

12. Action as below:

Put into the material, automatic feeding, automatic positioning,

automatic cutting, can be cutting round, square shaped, head material

and tail material are automatically separated.

HONGE PRECISION INDUSTRIES CORP.

Product Description :

• 小孔徑高精精密深孔鑽孔機<br />

• 此機器用於生產小孔徑的零件钻孔加工,尤其針對醫療的植入性器械 例如脛骨釘的深孔加工<br />

• 機器的特殊設計及內藏式高速主軸可降低噪音及震動,適合精密的深孔加工<br />

<br />

CHIN MING PRECISION TOOLS CO., LTD.

Product Description :

For Ultra-Hard Material Machining

(For Carbide, SiC, Al2O3, Si3N4 and ZrO2 Machining.)

------------------------------------------------------------

PCD Helix Flute End Mills- Multi-Flute:

★ Multi-flute decreases cutting resistance and makes high efficiency.

★ Applies to high precision machining of carbide and ceramics.

PCD Helix Flute Drilling:

★ For carbide, ceramics, aluminum, copper, graphite and carbon fiber drilling.

PCD Ball Rolling Cutter:

★ Special cutting edge and high accuracy R of ±0.005mm realize high quality mirror polished machining.

★ Applies to carbide and hardened steel(≦70HRC) mirror polished machining.

PCBN Helix Flute End Mills:

★ For hardened steel(HRC45~65°) and powder metallurgy machining.

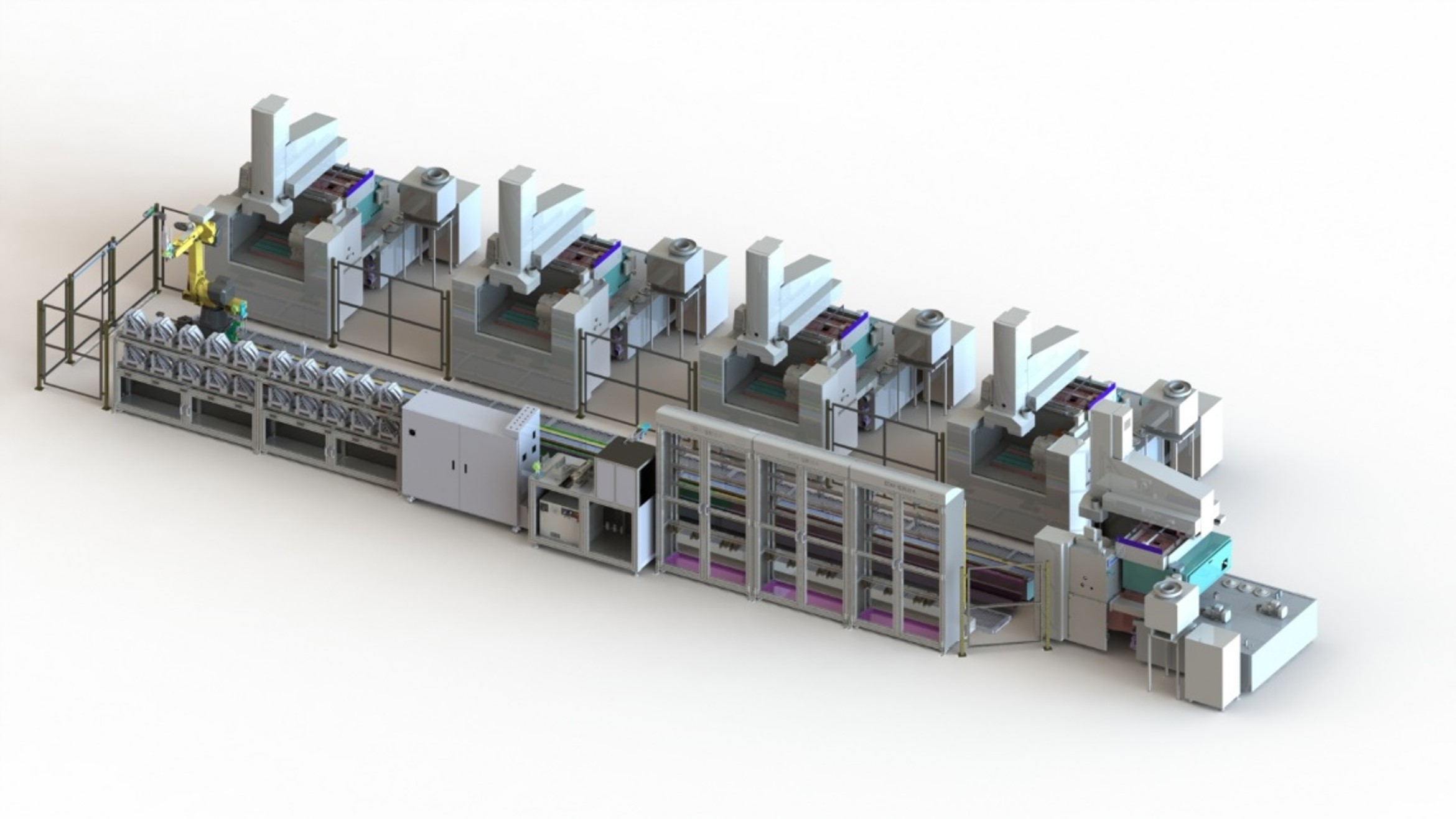

OSCAR E.D.M. COMPANY LTD.

Product Description :

Quick Integration

EX/EXD Series electrical discharge

machine, capable of easy integrated with

MES system, online measurement,

storage system and etc via OPCUA, API.

Smart Production line

Actual application on automobile moulding industry in

Europe. EX series sinker EDM integrated with MES and

milling machine where perform the production just-intime

without any interruption. By increasing 30% of

overall equipment effectivenss (OEE), 2 EDM will then

bring out extra 3,000 hours working time per year