Theme

Digital Transformation

Green Transformation

JIN TAIRY ELECTRIC CO., LTD.

Product Description :

JPS Technical Specifications

• Input voltage regulation range: rated voltage±15%

• Output efficiency: more than 95%

• Output stability rate: rated voltage±1%

• Waveform distortion: No distortion (compared with input waveform)

• Overload capacity: Above 150% of the rated output current

• Working environment: -0C~+40C

• Induction time: less than 0.1 seconds (less than 5 weeks)

• Working humidity: 95%

JPS Features

• Intelligent logic voltage regulation method

• Self-detection function

• LED indicator on the panel

• Patented bypass device included

• Large-range over-high and low-voltage protection device

• Under-phase instantaneous power failure short-circuit protection device

• Prevent activation of over-voltage device (SOVP)

Electronic double circuit panel design

• The internal panel voltage can monitor the three-phase voltage

• The DIP switch function is easy to set up

• Separated voltage stabilization design, three-phase unbalanced 100%

• Taiwan Patent No. 60215 62577

• Mainland Patent No. 12559 5390066

NINE-9 CUTTING TOOLS CO., LTD.

Product Description :

Nine9 chamfer mill is designed for chamfering and countersinking with an indexable insert.

The insert is a specifically designed for use in high speed machining ; the multiple flutes

provide for increased feed rate, optimizing performance and reducing cutting time.

High performance chamfer tool for upgrading your machining process.

For front and back chamfering. Eliminates 2nd operation or deburring time.

● Excellent Repeatability

• Smallest Indexable counter sink, diameter ø7 mm.

• The insert is dual-relief angle, specially edge honning and optimized coated for high cutting speed.

• Optimized the number of teeth on the holder to achieve higher feed rate.

● Economical

• Each insert has 4 cutting edges.

• Long tool life.

● Applications

• For front and back chamfering.

• 90° counter sink and 45° chamfering.

• For counter sink, circular chamfering, contour chamfering and face milling.

TAIWAN MORE-CASH VILLAGE CORP.

Product Description :

1.Convenient Design

X, Y axis workable professional structure enhanced high-

performance cutting accuracy.

2.Cutting Capacity

Cutting diameter: Ø3~16mm;

Cutting length of work-piece end: 15mmL/max;

3.Patented Radius cutting by Dual-motor driver

The hardened treatment steel is controlled well in virtue of

natural dissipation characteristic, cutting time is greatly

shortened as the work-piece is simultaneously rotated while

cutting.

4.Quick-Work-Changing System

The work-piece is quickly exchanged with prime quality 3-Jaw

chuck system.

5.Cooling System

Dry cooling is able to connect with various pressurized air and

vacuum cleaner achieved perfect cooling effect.

6.Cutting Disc

SD#100 for Carbide, CBN#100 for HSS

7.Optional Grinding Wheel For GS-13 GS-13

SD#100 thickness 5mm, 10mm for Carbide, CBN#100

thickness 5mm, 10mm for HSS

A.Carbide end mill cutting efficiency on GS-13

■ Ø 10mm 4 flute carbide end mill is cut by SD#100 cutting

disc takes 55 seconds.

■ Ø 16mm 4 flute carbide end mill is cut by SD#100 cutting

disc takes 100 seconds.

B.HSS end mill cutting efficiency on GS-13

■ Ø 10mm 4 flute HSS end mill is cut by E60WA cutting disc

takes 60 seconds.

■ Ø 16mm 4 flute HSS end mill is cut by E60WA cutting disc

takes 110 seconds.

TAIWAN MACHINE TOOL CO., LTD.

Product Description :

The Machine Center for next generation — TLV-850II

Applied field: general hardware processing, mold processing, precision parts

TLV-850II is known for its stability and capability of manufacturing with its high rigidity, which adopts the advantages from TLV-850. Furthermore, it applies the structure which fits the current trend.

-T-slot is used with the common specialization: 18mm

-Z-axis is adopted with the design of high rigidity, a bigger motor, and the strengthened structure so that it leads to perfect swarf performance.

-The tool magazine is well designed to provide the best stability.

-A stronger saddle and an enlarged base frame are also installed to stabilize the performance on cutting.

E-TECH MACHINERY INC.

Product Description :

ECG series high precision centerless grinder is different from other competitors, we use spectrum analyzer to precisely the machine base inner ribs and casting thickness for greater rigidity. We offer hydrodynamic alloy bearing spindle with best rotation accuracy, suitable for heavy duty jobs, and drastically increase the spindle longevity.

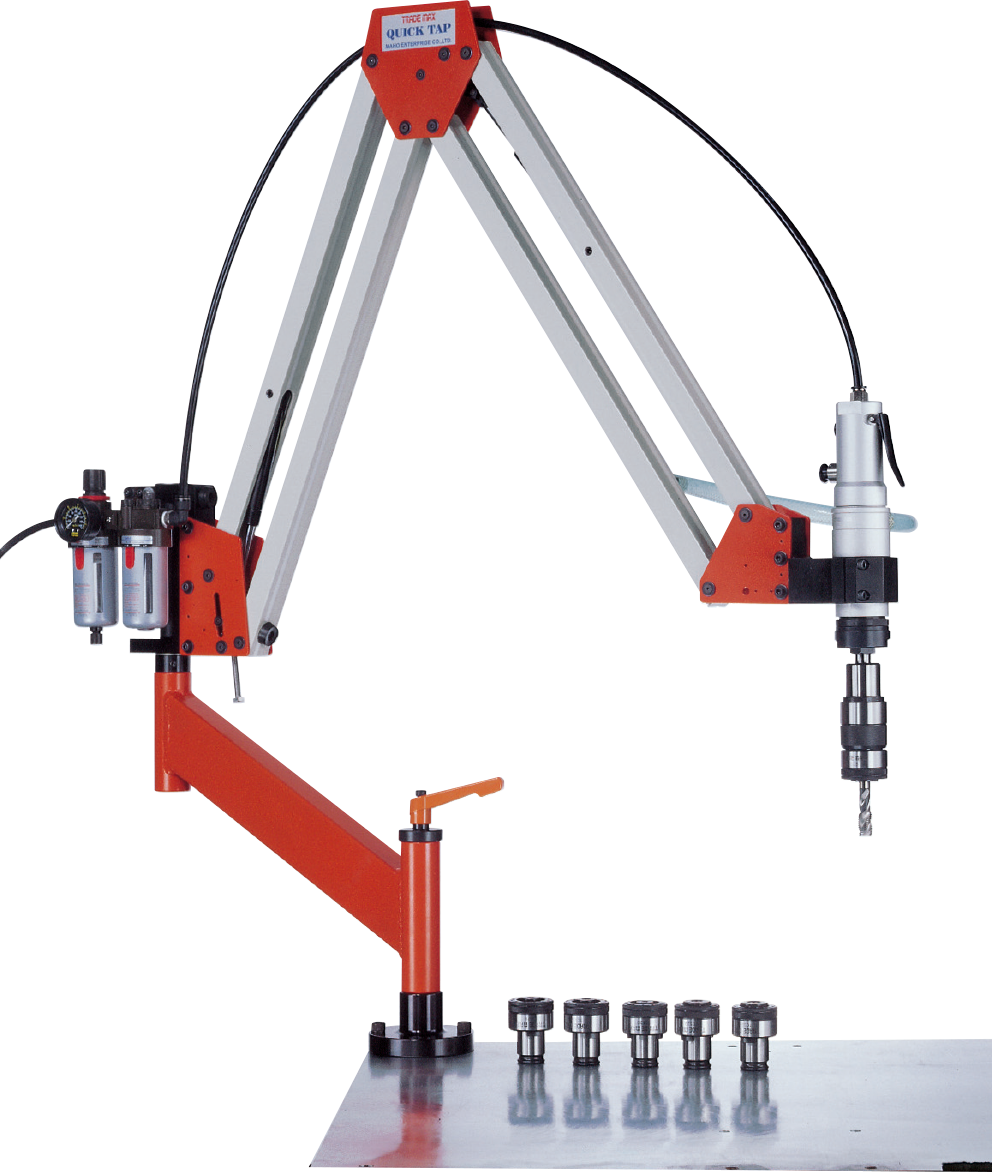

MAHO ENTERPRISE CO., LTD.

Product Description :

Pneumatic tapping machine is suitable for different size taps (from M2 to M27). The arm is equipped with lubricated for life bearings at all swivel points, provides weightless operation through the use of gas counter balance springs and permits the operator to bring the tap to the hole with ease.

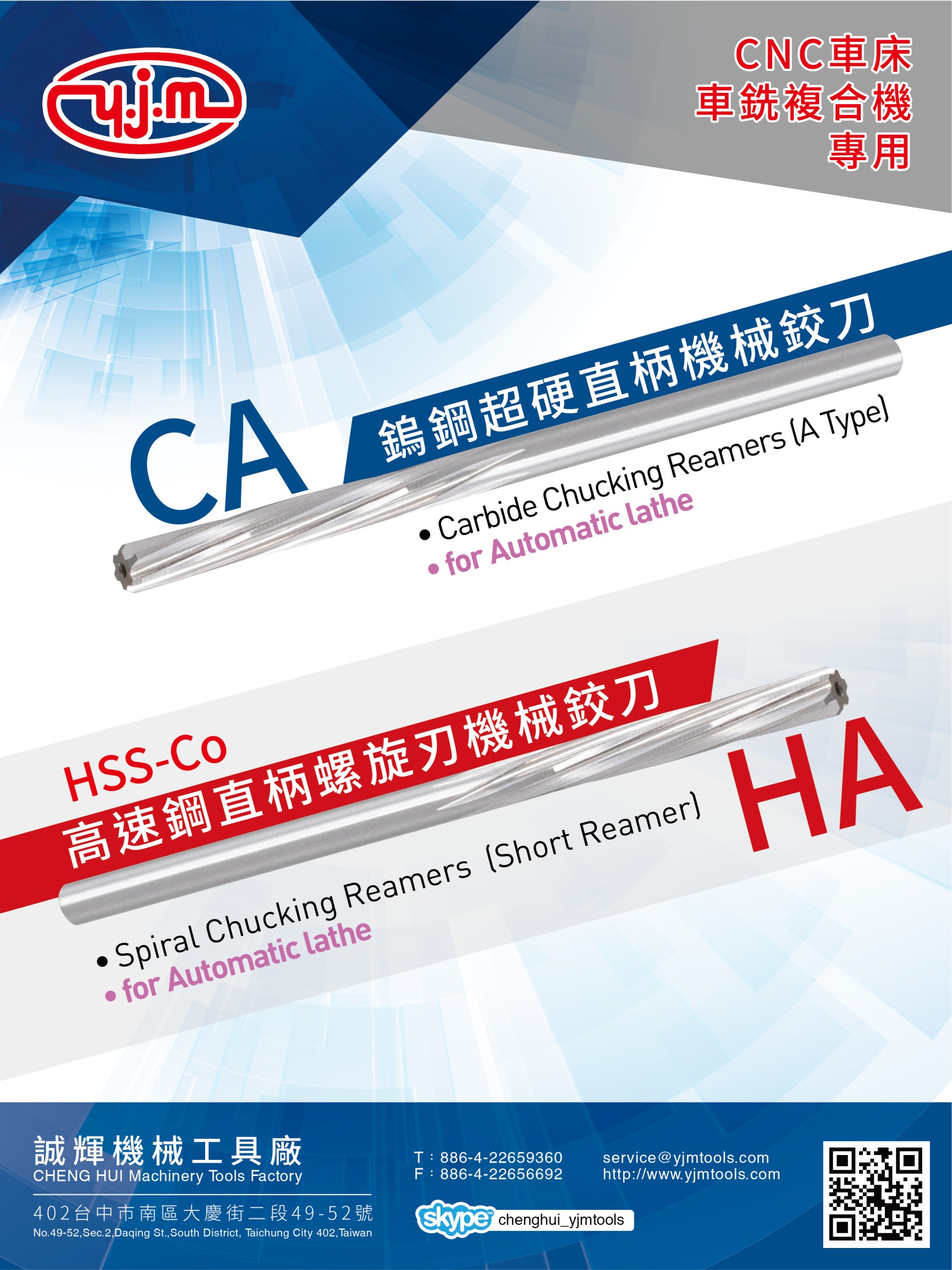

CHENG HUI MACHINERY TOOLS FACTORY

Product Description :

For Automatic lathe

Material: HSS-Co / Carbide

Tolerance:(+0~<+0.005)mm

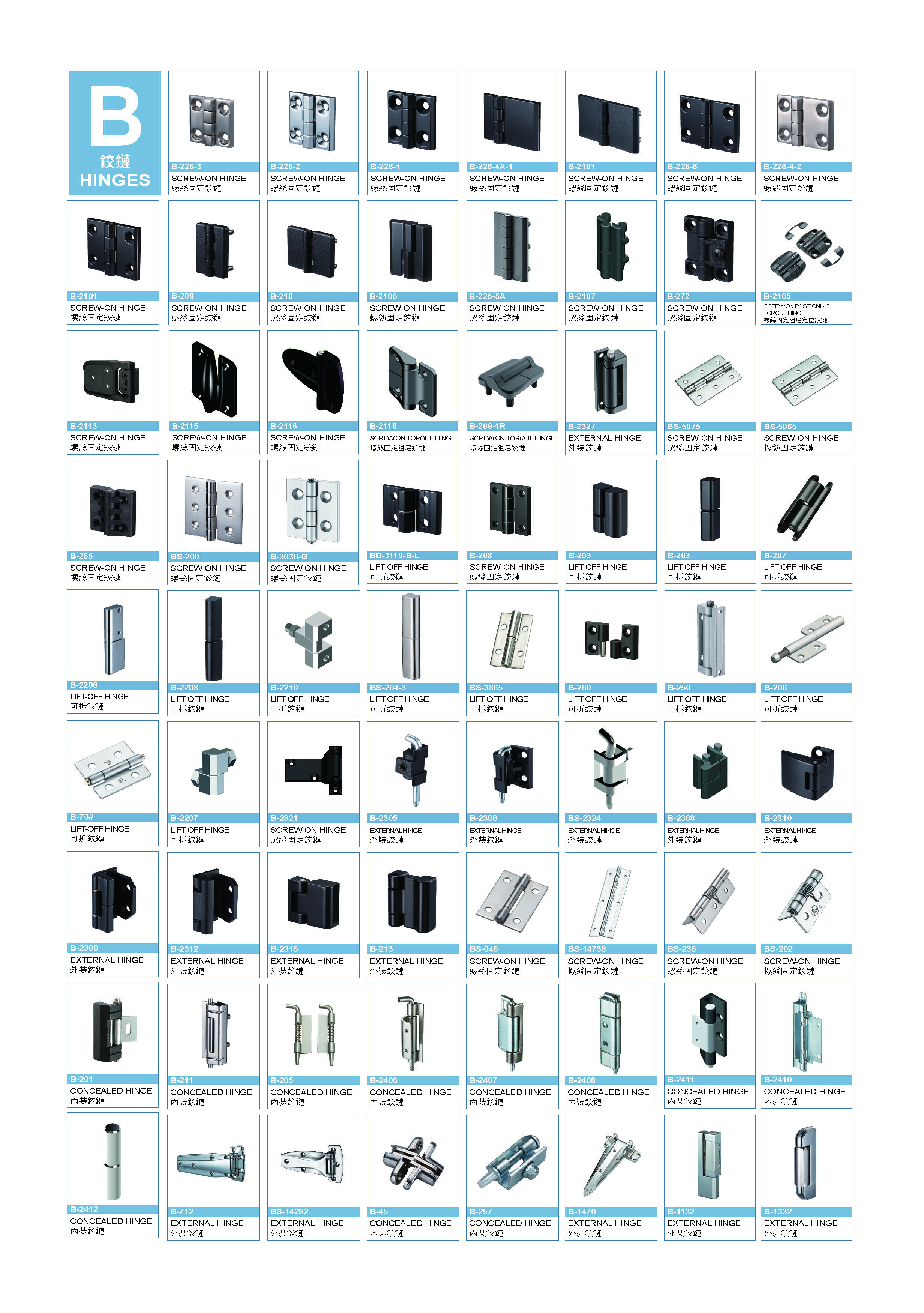

LEEKA INDUSTRIAL CO., LTD.

Product Description :

LEEKA provides a variety of industrial hinges for customers, including screw-on hinges, lift-off hinges, external hinges and concealed hinges.

The material is upon request and all products can be custom made.

EQP SERIES CO., LTD

Product Description :

Voltage Sensitivity: 10mV/(m/s²)±10%

Power Supply: DC15~36V

Constant Current: 0.5~10mA

Resonant Frequency: Approximately 40kHz

Frequency Response: 5~10kHz (±3dB)

Maximum Acceleration: 220m/s²

Shock Resistance: 49,000m/s²

Noise Level: Below 100μVRMS

Operating Temperature Range: -50~110℃

Detection Structure: Shear Type

Case Material: Titanium

Mass: Approximately 10g