Theme

Digital Transformation

Green Transformation

CAMPRO PRECISION MACHINERY CO., LTD.

Product Description :

NV series provide more Y-axis and more working area to meet various demands.

Heavy-duty roller type linear guideways on 3 axes which provide integration of heavy cutting ability from box way and fast movement ability from linear guide way.

Z-axis servo motor with brake replaces counter-balance to provide optimal surface accuracy on 3D machining.

Pretensioned class C3 precision ballscrews on 3 axes help to eliminate blacklash.

Bearings with dust-protection device are assembled by 3 sets both in the front and rear.

One-piece column which designed with shoulder to support tool magazine to decrease vibration and increase the machine stability while tool changes.

Optional max. 4/5-axis table diameter allows more working area and less interference between cutting tools and workpieces.

GSA TECHNOLOGY CO., LTD.

Product Description :

Equipped " double-cam-plate" for indexing mechanism,with compact design & high durability,suitable for heavy cutting of precision。

Driving source per hydraulic to turning tool-disc,indexing and clamping / unclamping,precisely and correctly。

Smart selection of nearby tools,controlled via proximity-detector and PLC programming,no error of tool-disc change。

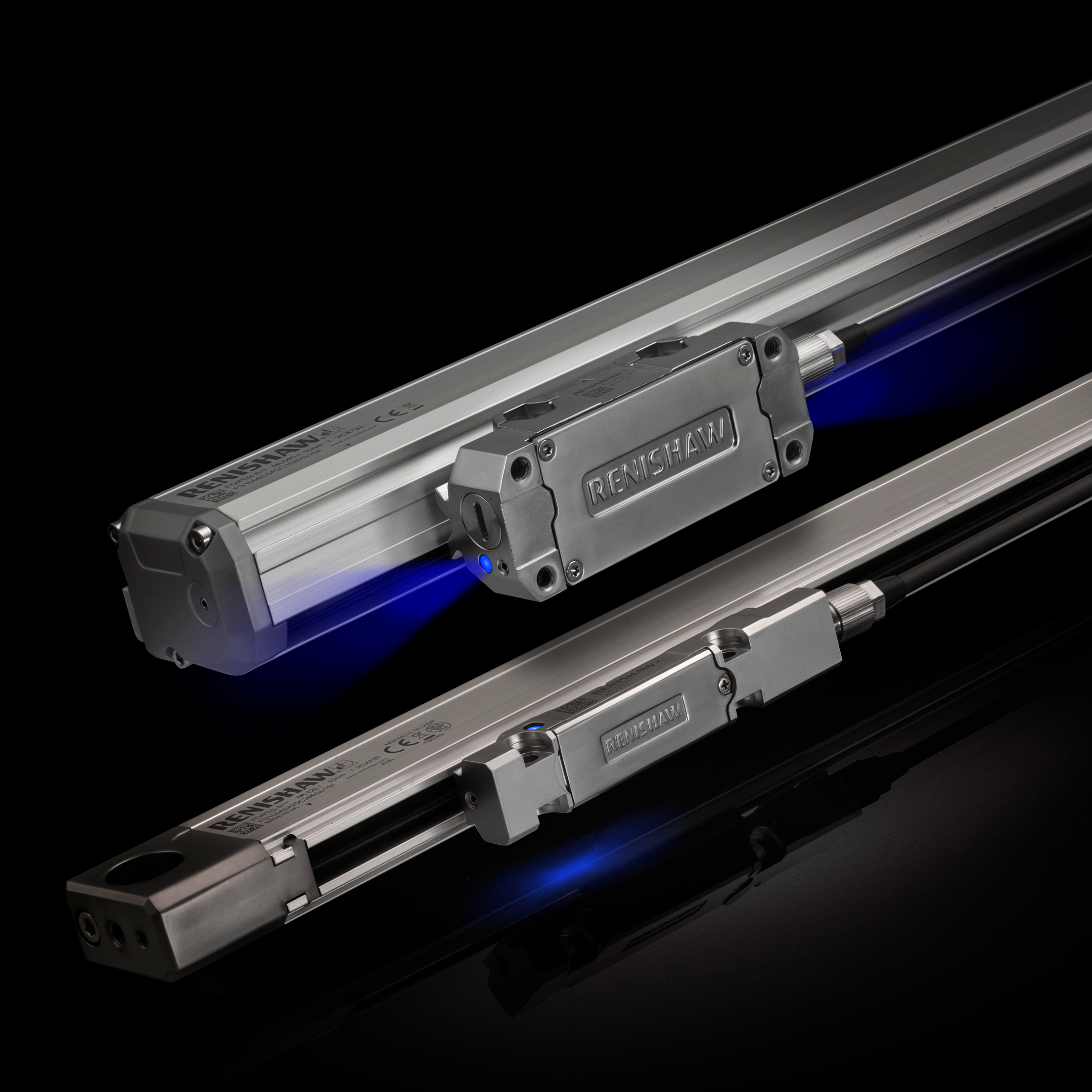

Ametek Taiwan Corp., Ltd.

Product Description :

PGI NOVUS: Fully automatic, ultra-high precision measuring system for surface finish, contour, 3D and diameter.

FTS LASER:Surface finish and contour instrument of high precision & large range.

i-Series PRO:High resolution surface finish and contour instrument for precision machining.

Intra & Surtronic Roughness:High precision surface finish and contour instrument for workshop and quality inspection room measuring & Super durable portable roughness testers.

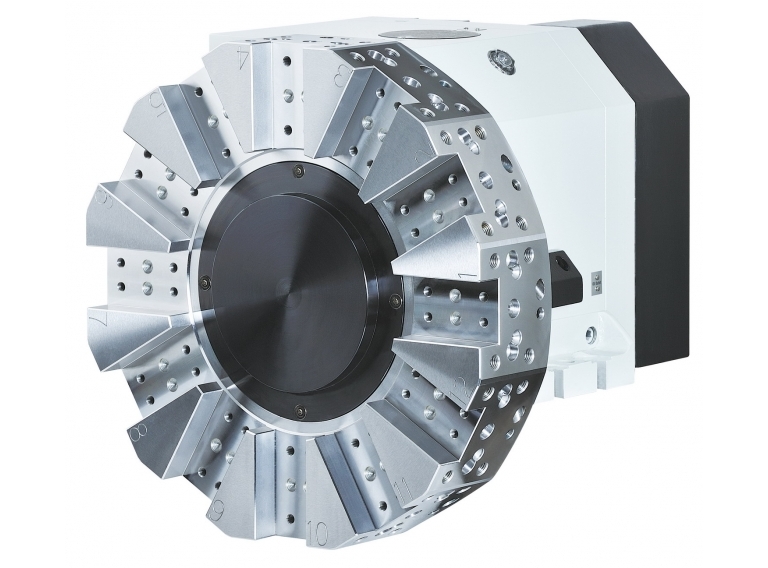

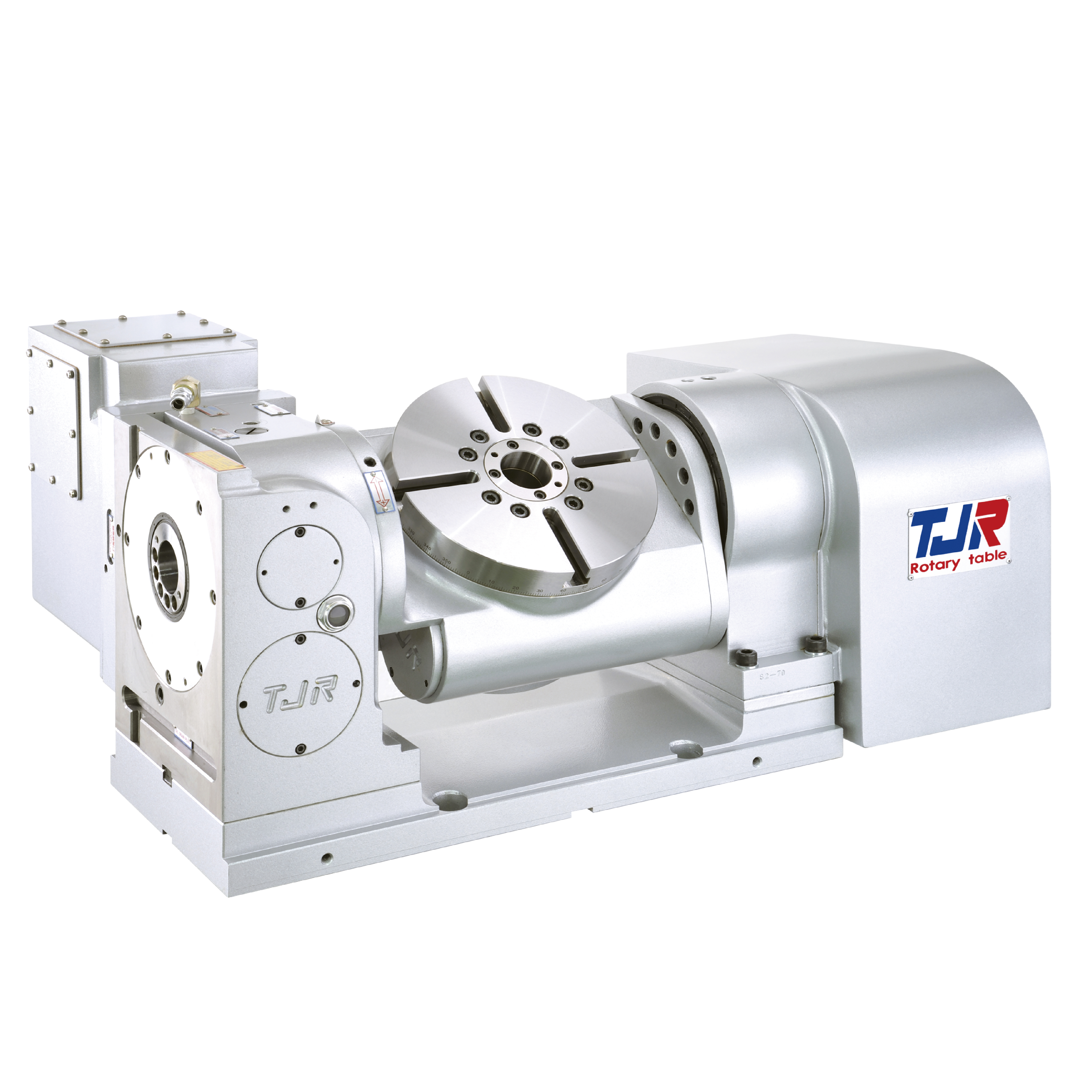

TJR PRECISION TECHNOLOGY CO., LTD.

Product Description :

① Both the tilting axis and rotary axis use large-diameter radial & axial bearings.

② Because the tilting axis normally needs to bear heary load, Japanese-made worm and worm gear are employed to improve wear resistance and precision of the tilting axis.

(Its wear life is 2.6 times longer than aluminum bronze PBC3.)

③ Anti-wear alloy steel worm gear is optional.

④ A hydraulic brake for the tilting axis is optional.