Theme

Digital Transformation

Green Transformation

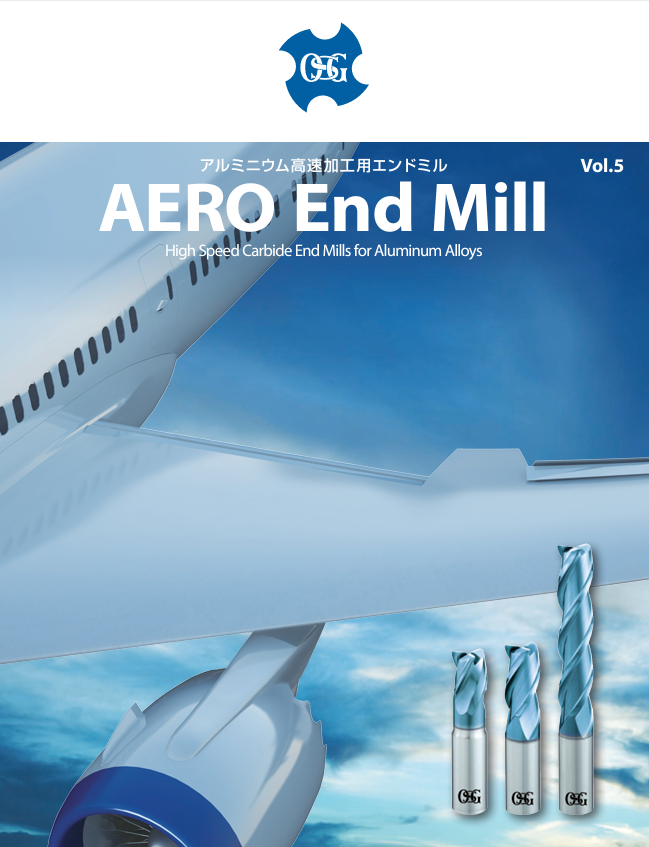

TAIHO TOOL MFG. CO., LTD.

Product Description :

The AERO series is very suitable for high-power equipment above 80KW.

It has a sharp cutting edges and grooves for great efficiency of discharging the chips. The coating is OSG's diamond coating with glossy surface. This bright and smooth surface optimizes the performance of the end mill, especially in aluminum alloy that weldability and lubricity are required.

The 3-short-blade type and center jet type (AERO-ETS, AERO-O-ETS) are corner radius end mills applied to roughing and finishing.

The 3-long-blade type and extra long blade type (AERO-ETL, AERO-EXTL) are corner radius end mills applied to roughing and finishing.

The 2-short-blade type (DLC-AIR-EDS) is corner radius end mills applied to roughing and finishing.

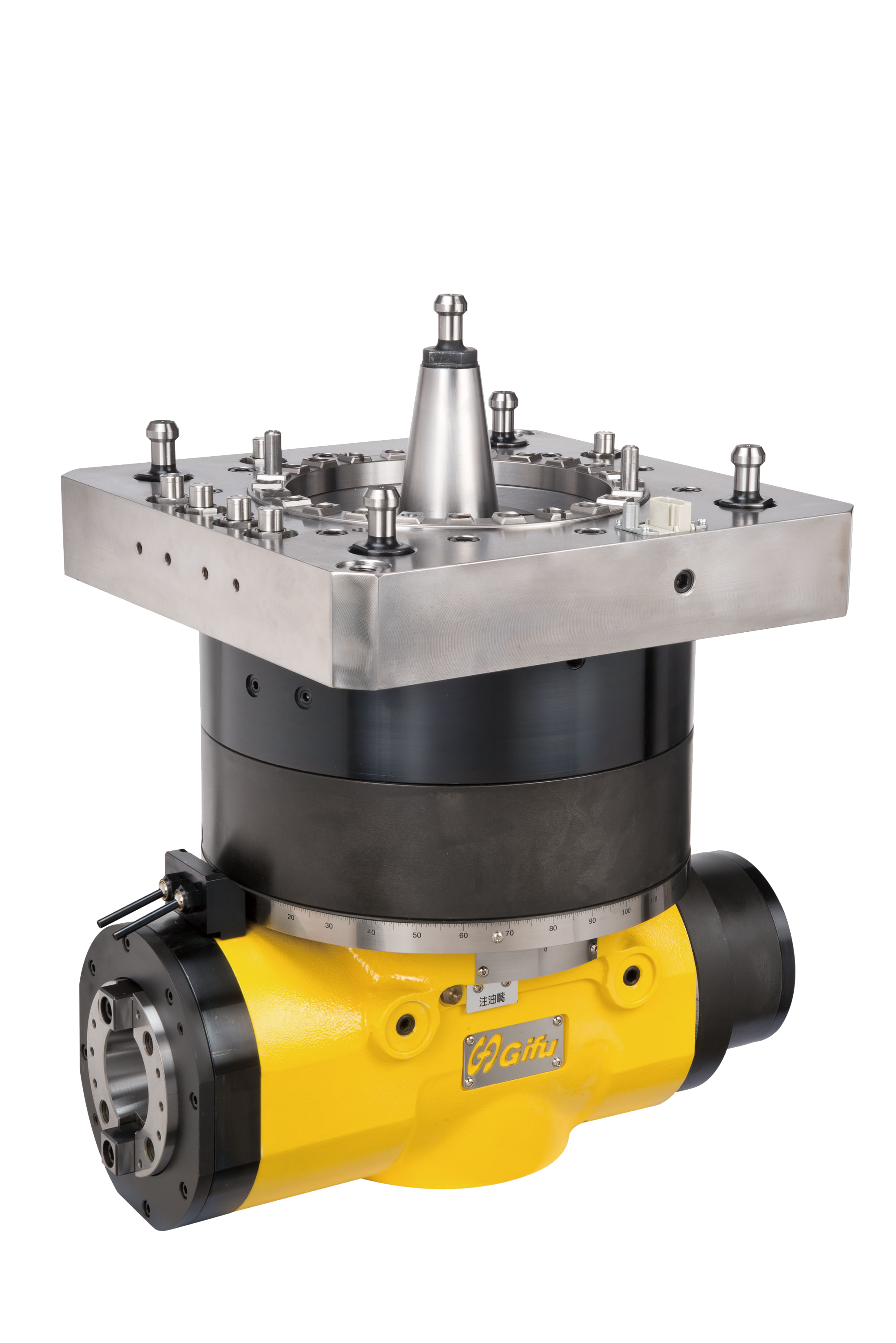

GIFU ENTERPRISE CO., LTD.

Product Description :

Model:Semi-Auto 90-degree CTS Milling Head (Maximum Torque:1000N.m) (Maximum RPM:2000r.p.m)

1.The exquisite design helps to reach the purpose at the most limited space.

2.Adopts spiral bevel gear with high rigidity and accuracy to keep reliable running and long life time of the product.

3.High torque transmission and high cutting efficiency.

4. The hydraulic tool pulling design of the spindle makes easy tool loading.

5.The design of extension body is exquisite with solid structure.

6.High accuracy, low vibration and good dynamic rotation accuracy.

7.It can be adopted for CTS system.

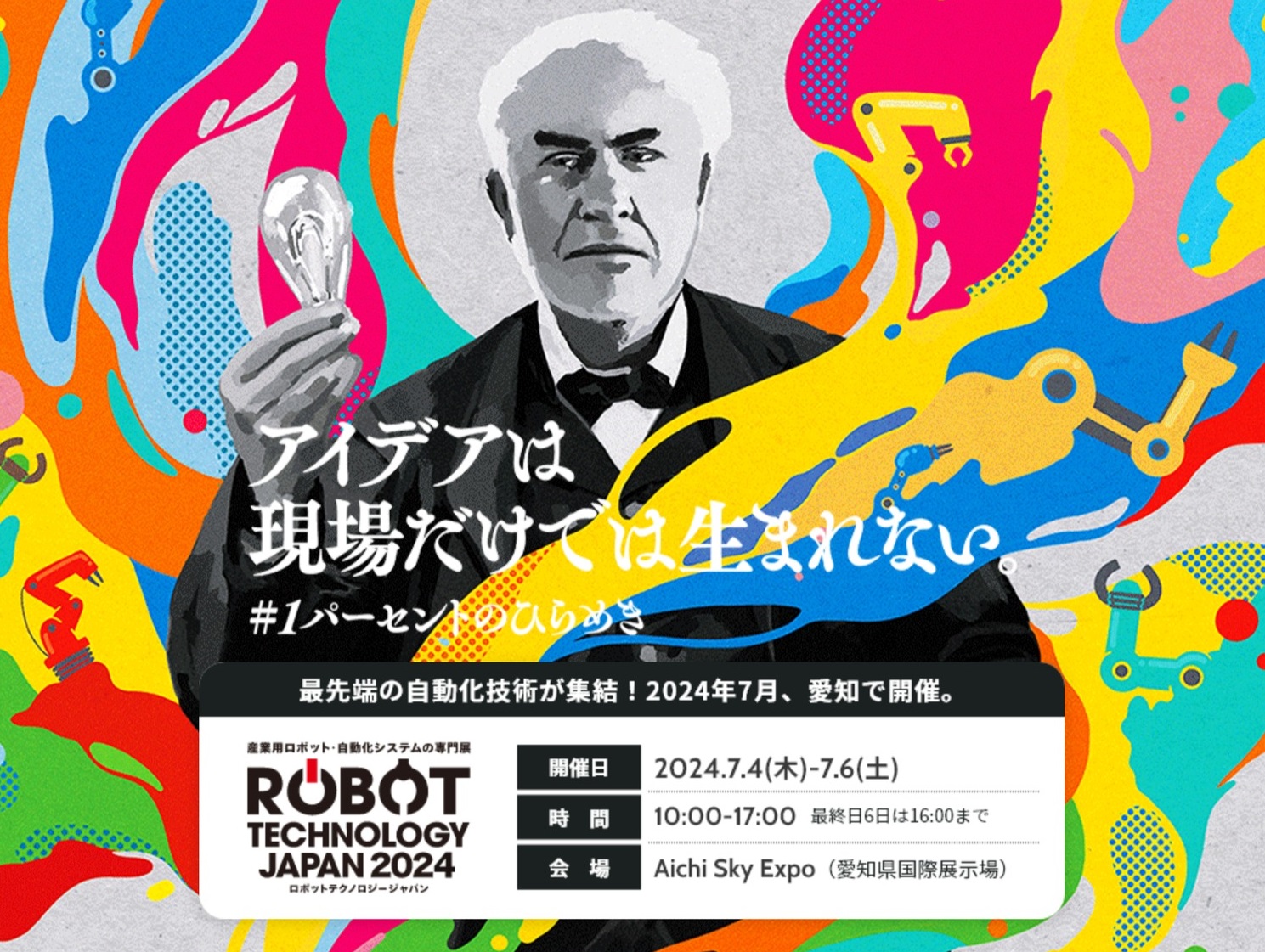

Lotus Business Information Co., Ltd.

Product Description :

This is one of the biggest B to B exhibitions held in “Central Japan,” an industrial area with a cluster of manufacturers. In 2022, 202 companies with 1,096 booths were registered in the exhibition.

The scope of the exhibition is specialized in “industrial robots” used in manufacturing sites and logistics bases, “devices and equipment” with industrial robots integrated in them, and “automation systems” using like AGVs/AMRs.

TONGTAI MACHINE & TOOL CO., LTD.

Product Description :

‧The VP-12 combines the advantage of a smaller footprint with a large internal machining space, equipped with a high-speed spindle to meet the requirements of efficient and precise machining.

‧Direct-drive spindle BBT-40 provides a high rigidity and high efficiency.

‧The tool magazine allows for flexible tool placement and pre-selection, coupled with a high-speed ATC mechanism to reduce non-cutting time, showcasing efficiency similar to drilling and tapping machining centers.

‧High quality spindle and high rigidity structure design subject to high standards of machine accuracy to achieve good cutting performance.

‧By Tongtai production system, we check every detail process from design, manufacturing, assembly and QC.

GENTIGER MACHINERY INDUSTRIAL CO., LTD.

Product Description :

1. The structure design highlights the stability during high-speed processing.

2. The base design provides multi-angle processing and improves support strength.

3. The tool length measurement device is designed inside the ATC door to avoid contamination.

4. Equipped with high-precision DD motor rotary table.

5. Sheet-metal integration reduces assembly time.

6. Internal bevel design to avoid chip residue.

7. Multi-window device improves operation convenience.

8. Could be equipped with automation/remote monitoring to improve production efficiency.

9. Ergonomically designed to reduce operator fatigue and improve safety.

10. Small footprint improves equipment utilization.

11. High Speed, stability, and precision provide a competitive edge in precision mold and die machining.

FALCON MACHINE TOOLS CO., LTD.

Product Description :

Improved grinding performance, precision and stability

Chevalier's FSG-20/24ADIV Series of surface grinders now includes four new machine sizes, along with several newly designed features: a traveling column structure to further reduce vibration and achieve higher accuracy; a spindle that can withstand heavy load grinding; and a double-V guideway for smooth, stable longitudinal movements. Fully supported worktable design. Maximum table speed: 30 m/min (98.4 fpm), increases processing efficiency. Integrated machine-body temperature control system greatly improves accuracy and stability.

These four larger sizes, along with the entire FSG-20/24ADIV Series, offer several design features to shorten processing and non-processing preparation while delivering high-precision workpieces: iSurface control, variable speed spindle, constant surface speed, smart grinding path and in-machine manual dynamic balancing.

The driving forces behind this series pave the way to smart manufacturing by meeting the current grinding demands and standards required by the automotive, electric vehicle, mining, aerospace and job shop industries.

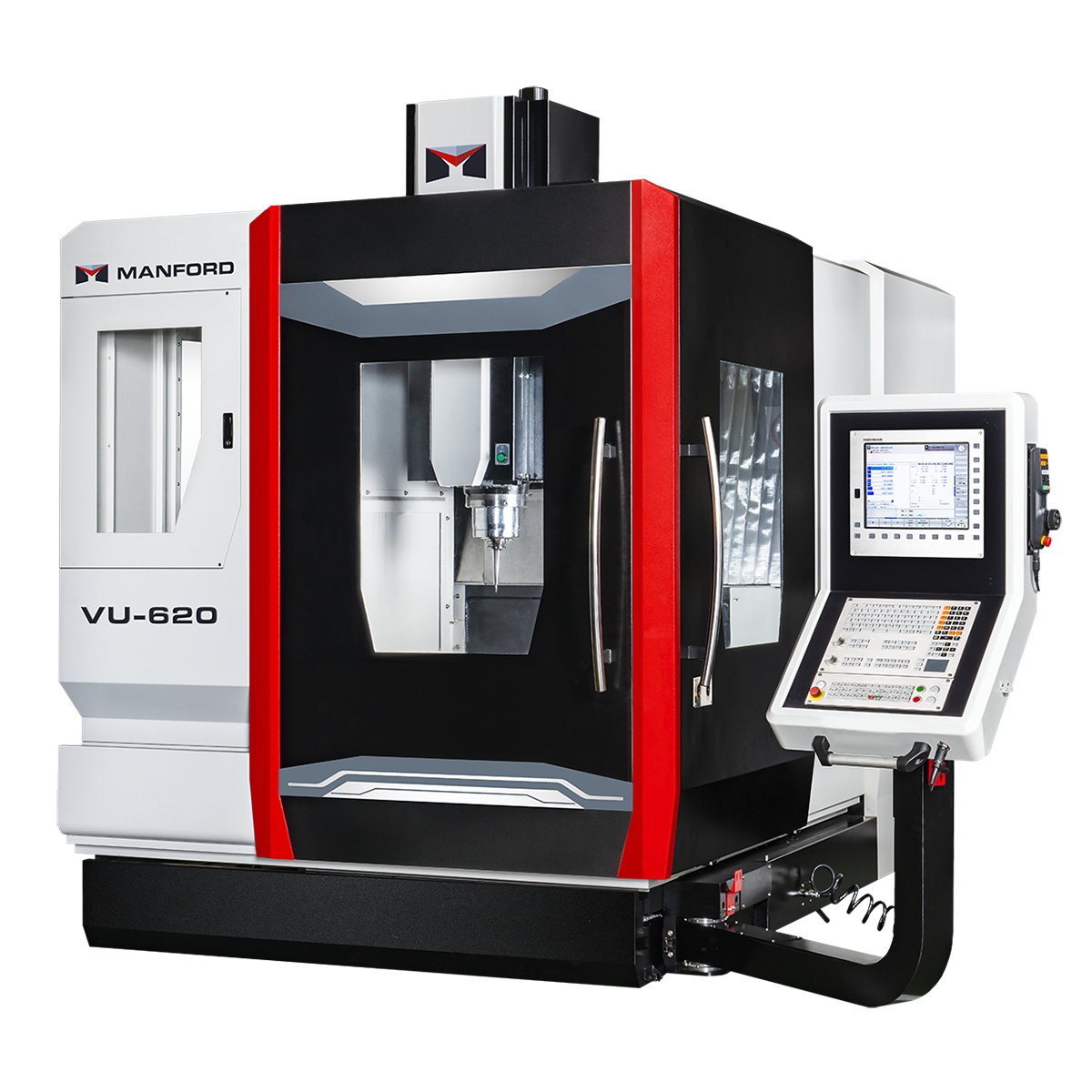

MANFORD MACHINERY CO., LTD.

Product Description :

Turnkey solution of VU-620 product line enables Manford to process and optimize parts efficiently, enhance productivity and accuracy. VU-620 adopts low-pollution components and complies with eco-friendly regulations. Occupying compact floor dimensions is also one of the features of VU-620.

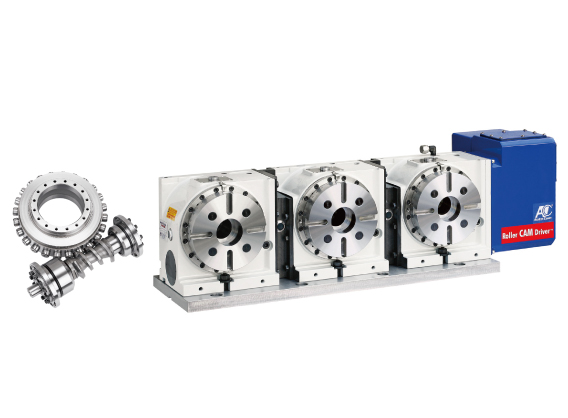

VU-620 offers high speed, high accuracy and more reliable quality. Twin doors design with wide open space is easy for loading workpiece. Movable column C-shape provides superior rigidity. Rotary table with one-piece iron casting provides excellent ductility and greater anti-vibration. Rotary table selection: standard worm gear, or double DD motor.