Theme

Digital Transformation

Green Transformation

DKSH Taiwan Ltd.

Product Description :

EVALED® RV F is the line of mechanical recompression evaporators designed to reach the highest level of reliability in heat transfer, with minimum impact in terms of fouling and scaling.

High efficiency forced circulation shell & tube heat exchanger with horizontal tubes allows wastewater concentration up to the salts solubility limits and to manage also suspended crystals.

Wastewater is constantly treated: the distillate and the concentrate are continuously separated and then simply discharged through a pump. Heat is recovered by cooling the two outlet streams using the inlet effluent.

Available in different materials to treat different effluents containing dissolved salty, organic compounds and even the most aggressive salted wastewater (high chlorides content), produced by various industries.

The MVR is the lowest energy consumption evaporation technology.

• Maximum water recovery;

• Effective reduction of waste to be disposed of;

• Modular and flexible;

• Intuitive HMI;

• Plug & play;

• Minimum labour.

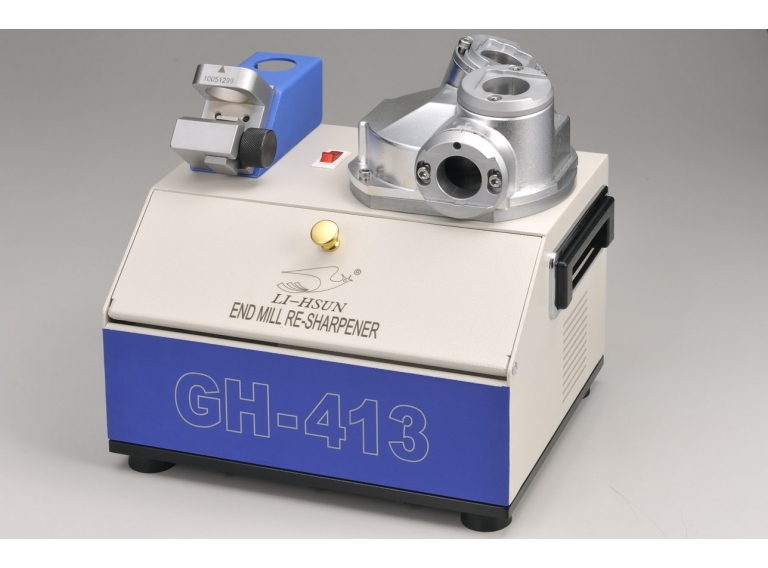

GP MACHINERY CO., LTD.

Product Description :

The Hiteco birotary heads series Tilt HX PLUS (90 °) are ideal for light alloys, composite materials and plastics working. Discover the liquid cooled electrospindles available with the various configurations.

Advantages:

1. Designed for machining composite materials, plastic and light alloys

2. Optimisation of the machining times thanks to the high positioning speeds

3. Excellent stiffness despite the light weight

NINE-9 CUTTING TOOLS CO., LTD.

Product Description :

Nine9 chamfer mill is designed for chamfering and countersinking with an indexable insert.

The insert is a specifically designed for use in high speed machining ; the multiple flutes

provide for increased feed rate, optimizing performance and reducing cutting time.

High performance chamfer tool for upgrading your machining process.

For front and back chamfering. Eliminates 2nd operation or deburring time.

● Excellent Repeatability

• Smallest Indexable counter sink, diameter ø7 mm.

• The insert is dual-relief angle, specially edge honning and optimized coated for high cutting speed.

• Optimized the number of teeth on the holder to achieve higher feed rate.

● Economical

• Each insert has 4 cutting edges.

• Long tool life.

● Applications

• For front and back chamfering.

• 90° counter sink and 45° chamfering.

• For counter sink, circular chamfering, contour chamfering and face milling.

SONG GIA INDUSTRIAL CO., LTD.

Product Description :

●精密鉸孔神器-浮動鉸刀柄,可解決以下問題:

1. 孔的直線行差

2. 鉸刀不耐用

3. 孔的尺寸擴大,尺寸精度達不到要求

4. 孔的中間大,兩頭小,圓柱度達不到要求

5. 內孔表面粗糙度達不到要求

6. 大批生產時無法保證孔徑尺寸的一致性 。

●浮動鉸刀柄的特點:

1.可透過360度浮動讓鉸刀對準下孔徑,避免對不準而造成擴孔或縮孔

2.徑向振幅抑制在5μm以下

3.提高鉸孔光潔度

4.彌補車床公差,提高鉸孔精密度

5.提高鉸孔的直線度和圓柱度

●浮動鉸刀柄可應用加工機械:鑽床、立式加工中心、研磨機。 可夾持工具:鉸刀、滾光刀

**產品連結→→https://www.songgia.com.tw/tw/products/other-tools/floating-reamer-holder

JEFFER MACHINERY CO., LTD.

Product Description :

This machine comes in a one-piece construction that has been heat-treated to achieve maximum rigidity. The rails are thermal treated and precisely ground to reach hardness of more than HRC 60˚. Furthermore, options are available to adopt rails of various lengths to meet different knife grinding requirements. The machine length can be customized for specific needs from 1,600 to 4,000mm. Rough and finish grinding wheels can be controlled manually and automatically. The minimum grinding wheel downfeed amount is 0.005mm and the spindle is equipped with an automatic cooling system which ensures excellent cooling effect. The SSG-8 employs an automatic lubrication system for smoother operation and longer service life.

SSG-8 Feature :

1. Knife tools movement type.

2. After grinding by coarse wheel and fine wheel, knife

tools can be sharp.

3. Force cooling system on motor shaft obtains better

cooling effect for the knives.

4. Grinding wheel lifting seat is used by ball bearing screw,

it can adjust up and down movement in precision.

5. Water splash guard and coolant tank are made of

stainless steel.

6. Grinding Capacity (Magnetic Chuck) LxW :

2500x200mm