Theme

Digital Transformation

Green Transformation

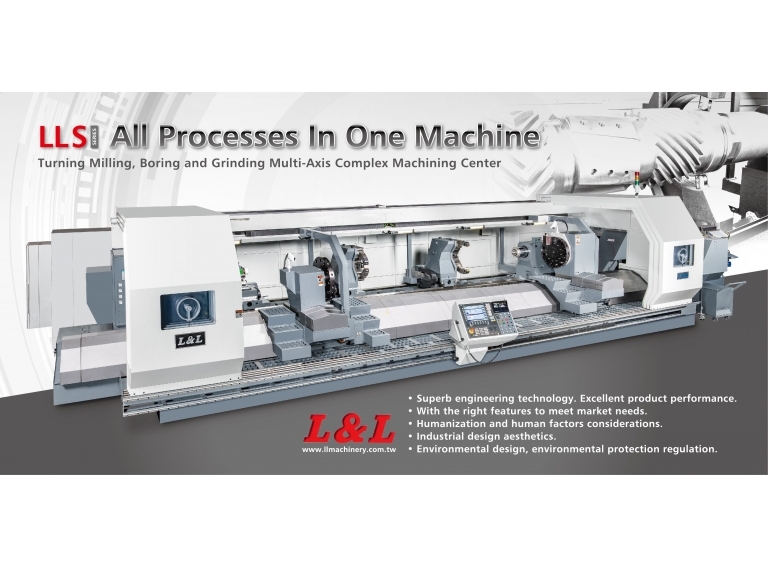

L & L MACHINERY INDUSTRY CO., LTD.

Product Description :

L&L LLS multi-axis composite cutting center machine, targeting the plastic rubber machinery industry, the application function exceeds customer demand:

a. Reduce the number of times of machining twice, reduce tool interference, and reduce work time by 50%.

b. Bed structure patent, one-piece casting, μ-level scraping process to ensure accuracy and stability.

c. Programmable tailstock, hydraulic center frame, independent chip removal device, programmable automatic door, high speed splash screen, full cover sheet metal design.

d. Full-cover design reduces the leakage of coolant, the design of the coolant collect plate for bed base, and the addition design of oil mist collector to reduce oil and gas pollution.

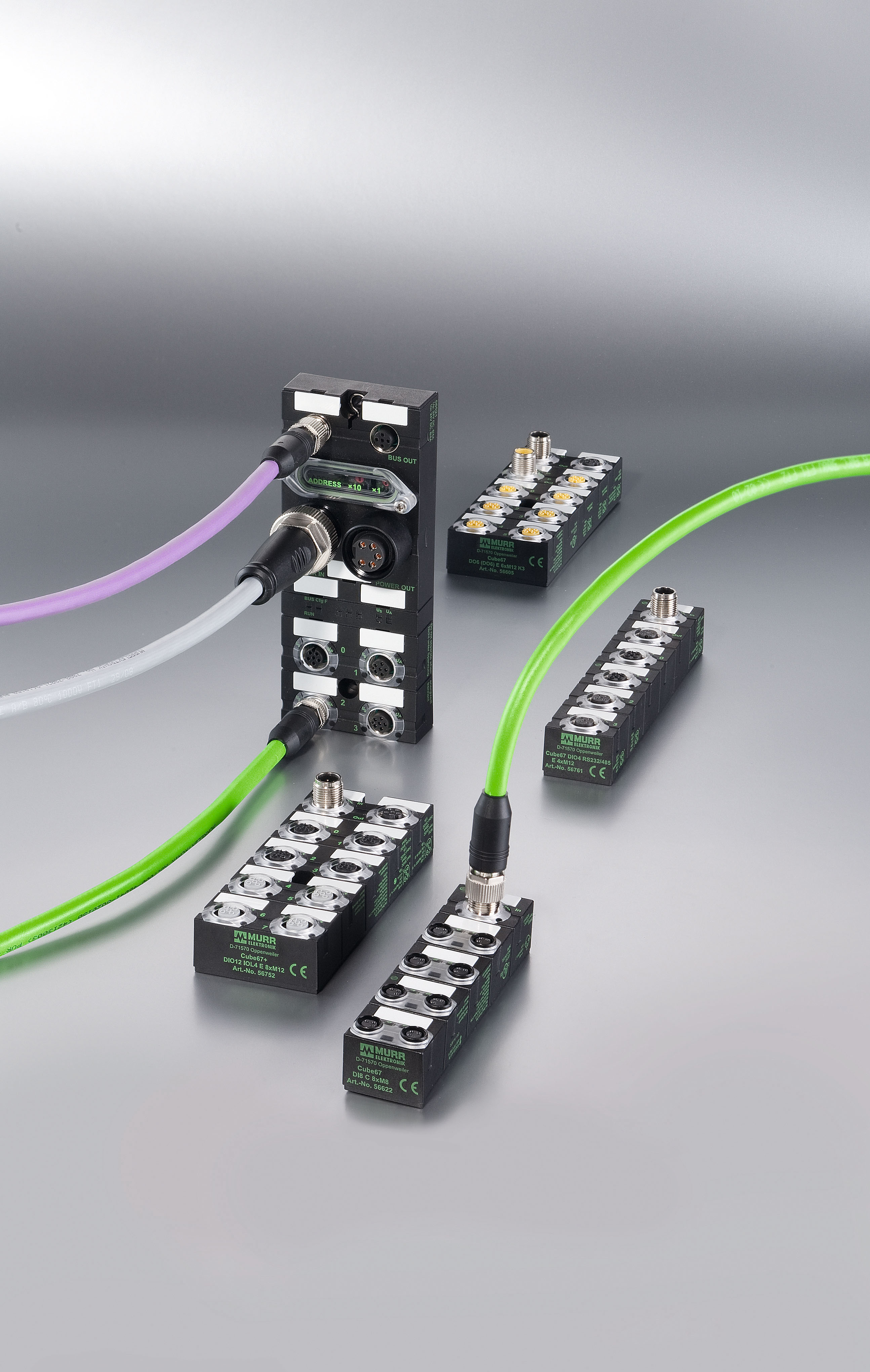

HIWIN TECHNOLOGIES CORPORATION

Product Description :

【ESG Sustainable Goal for Motion Control Components】

According to TrendForce research, the green factories will boost the global smart manufacturing market, which will reach $620 billion by 2026. As the concept of ESG sustainability has set off a wave of enthusiasm around the world, HIWIN linear motion components have also continued to focus on intelligent energy-saving innovation, providing simple, safe and modular designs to help customers upgrade from the inside out and embrace the trend of ESG energy saving!

The world’s first Intelligent 4.0 Ballscrew i4.0BS®, together with Intelligent 4.0 Guideway i4.0GW® and Intelligent Single-Axis Robot provide users to monitor health conditions of multiple machines and allow users to plan the production and pre-schedule the maintenance. The function of improving productivity and reducing carbon emission is also in line with the ESG sustainable goal.

-i4.0BS® multi-function sensors design with algorithm, effectively monitor the status of the Ballscrew. The users can monitor machines' conditions anytime.

-i4.0GW® sensor can be mounted on the block according to customers' demand. The system is fully compatible with i4.0BS®.

-The intelligent single-axis robot iSR has a modular design to meet the users' needs in various fields.

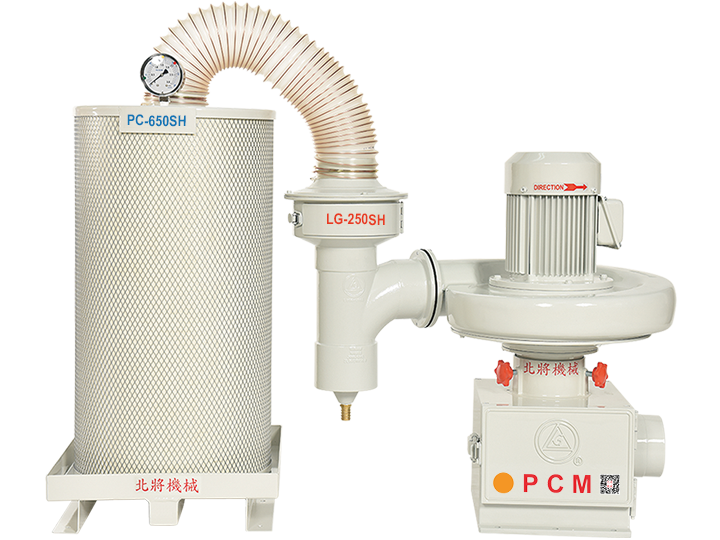

PEI CHIANG MACHINERY CO., LTD.

Product Description :

S系列經濟型 產品特色:

● 半油性切削液專用

針對水性切削液設計之HEPA濾材,有效過濾水霧懸浮微粒

● 高效淨化有毒物氣

再過濾油霧回收機餘氣、PM2.5懸浮微粒60%,配合二段式高壓油霧回收機,整體過濾效能達95%

油霧回收機本體特色 :

●機體材質鋁合金成型,重量輕,堅固耐用

●強力高風壓,最大可達320mmAq流量流速穩,過濾效能高

●使用感應式馬達,電量省 散熱快 適合長時間運轉

●結構式原理回收油霧,直立式設計,不震動,低噪音

●安裝容易,不佔空間,使廠內機械移位佈置更容易

●捨棄式濾網,10秒快速更換,保養容易,工安無慮

分離式油煙處理座特色

●標配之壓力錶:可輕易檢知是否有阻塞的情況 、 判斷濾材更換時間

●專利結構設計:由上往下之設計原理,以高風壓加速濾材所吸附的油氣集結快速垂降, 使壽命有效延長

●分離式之設計:因應現場需求,可直接安裝於機台上方或任意位置

●彈性多功組合:可單獨選購或配合任何有動力送風之末端空氣處理

● 免保養易更換:濾材無需保養,分離式之設計使濾材更換更加容易

適用範圍:

CNC車床、CNC铣床、CNC綜合切削加工機、CNC磨床、放電加工機、滾齒機、洗淨槽、防鏽油噴霧回收及會產生

白煙、細油氣、水霧、油霧之各種設備的回收淨化處理。

選配項目:

● 活性碳AC-650 ● 油煙處理器S-350 ●油煙處理器SH-650 ●側掛鐵架 ●直列式四腳架 ●並列式四腳架

HEIDENHAIN CO., LTD. (TAIWAN)

Product Description :

In addition to milling operations, the TNC 640 also combines operations from milling, turning, and grinding processes. This sets the TNC 640 apart as a high-end control within its field of application. It is particularly well suited to HSC and 5-axis simultaneous machining, including on fully automated machining centers. The TNC 640 stands for perfect surface quality, exceptional accuracy, and very short machining times combined with shop-friendly operation and programming. On a milling/ turning machine with TNC 640, you machine the complete work piece on one machine in whatever sequence is needed. You can switch back and forth regardless of the machine and its axis configuration. The TNC 640 makes all necessary adjustments, e.g. switching to diameter display and setting the datum in the rotary table center. Batch Process Manager allows you to optimally plan and execute production jobs with great ease. With Batch Process Manager you can flexibly define the sequence of your jobs and, prior to machining, check to ensure that all of the required tools are available and that the NC program will run without errors.