Theme

Digital Transformation

Green Transformation

ENSINGER ASIA HOLDING PTE. LTD. TAIWAN BRANCH

Product Description :

TECAPET PET polyester from Ensinger is specially formulated to provide improved toughness, and enhanced machinability. This PET polyester also offers excellent sliding and wear properties, and a low coefficent of friction. TECAPET's superior chemical resistance, non staining characteristics, and distinct lack of centerline porosity, makes it a desirable material for a variety of applications especially in the food industry that might involve solvents, cleaning chemicals, or direct food contact.

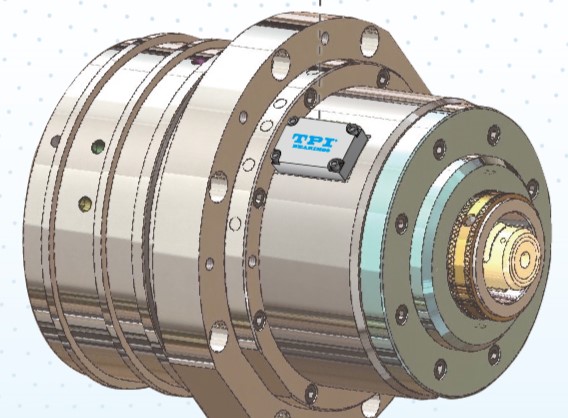

GRINTIMATE PRECISION INDUSTRY CO., LTD.

Product Description :

a.Equipped with exclusive hydrostatic bearing spindle system with high rigidity, low friction, and no wear features.

b.Spindle rotation accuracy within 1μm.

c.Equipped with THK/NSK high precision ballscrews, ensuring the zero backlash feeding.

d.High rigidity and high vibration resistance capability on hydrostatic spindle, comparing to the conventional ball bearing/dynamic bearing spindle during heavy cutting, it represents the high machining efficiency for more than 10 times and can greatly reduce the machining time & labor cost.

e.Our machines are 100% designed and manufactured in Taiwan,all casting components are processed of stress relieving to ensure the machine stability.

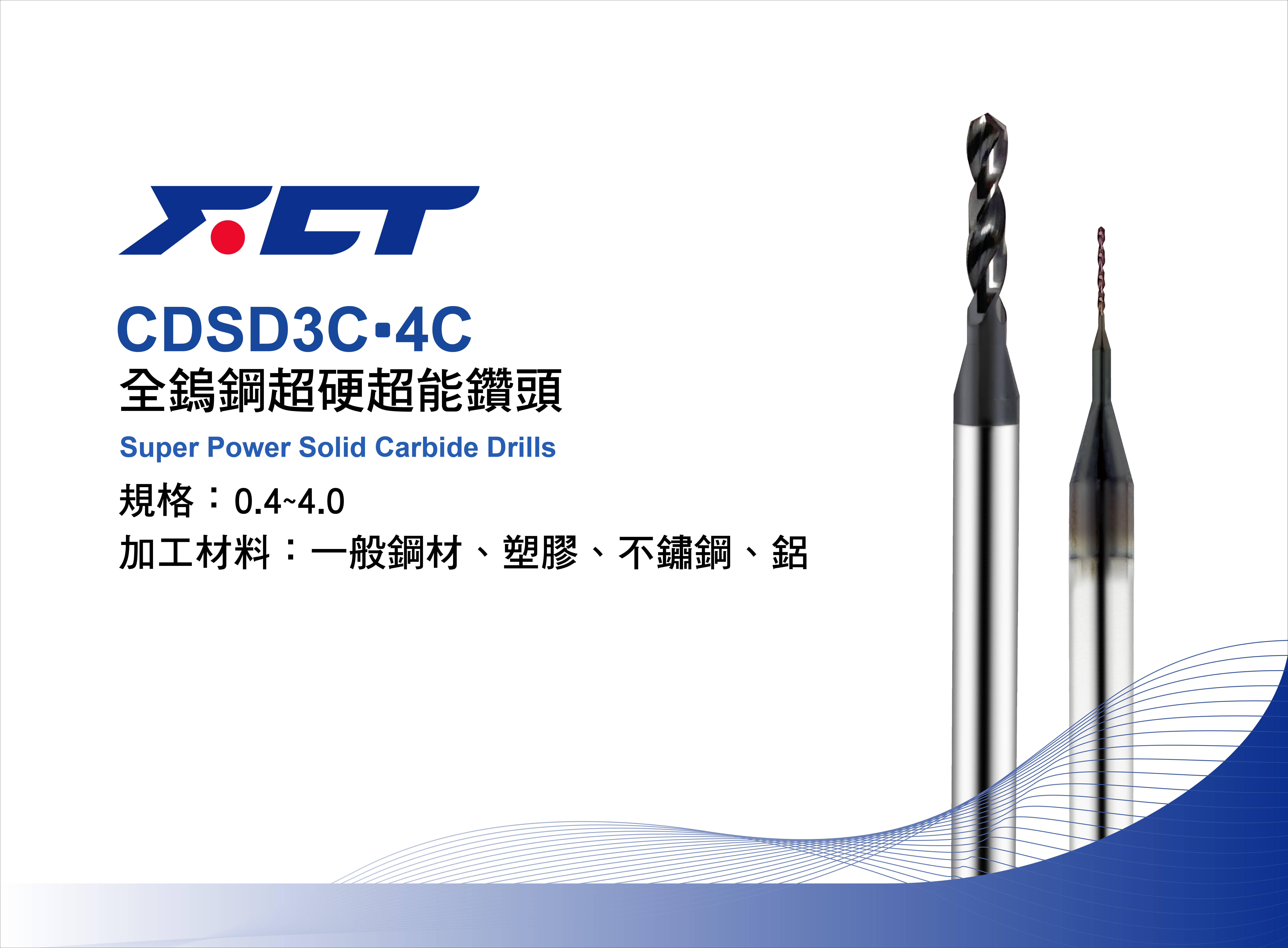

A Being Kou Tools Co., Ltd.

Product Description :

MicroCentric was founded in 1969. 50 years of advancing engineering and high-quality manufacturing has earned MicroCentric the reputation as the global leader in precision workholding technology. Each MicroCentric product is backed by superior design, the highest quality materials and precision workmanship for reliable, long term performance and unmatched accuracy.

MicroCentric is renowned for building workholding products of unmatched precision and accuracy. Most MicroCentric’s precision chucks have a standard repeating accuracy of .0001″ (0.002mm), and many models are accurate to within .00005″ (0.001mm).

OSCAR E.D.M. COMPANY LTD.

Product Description :

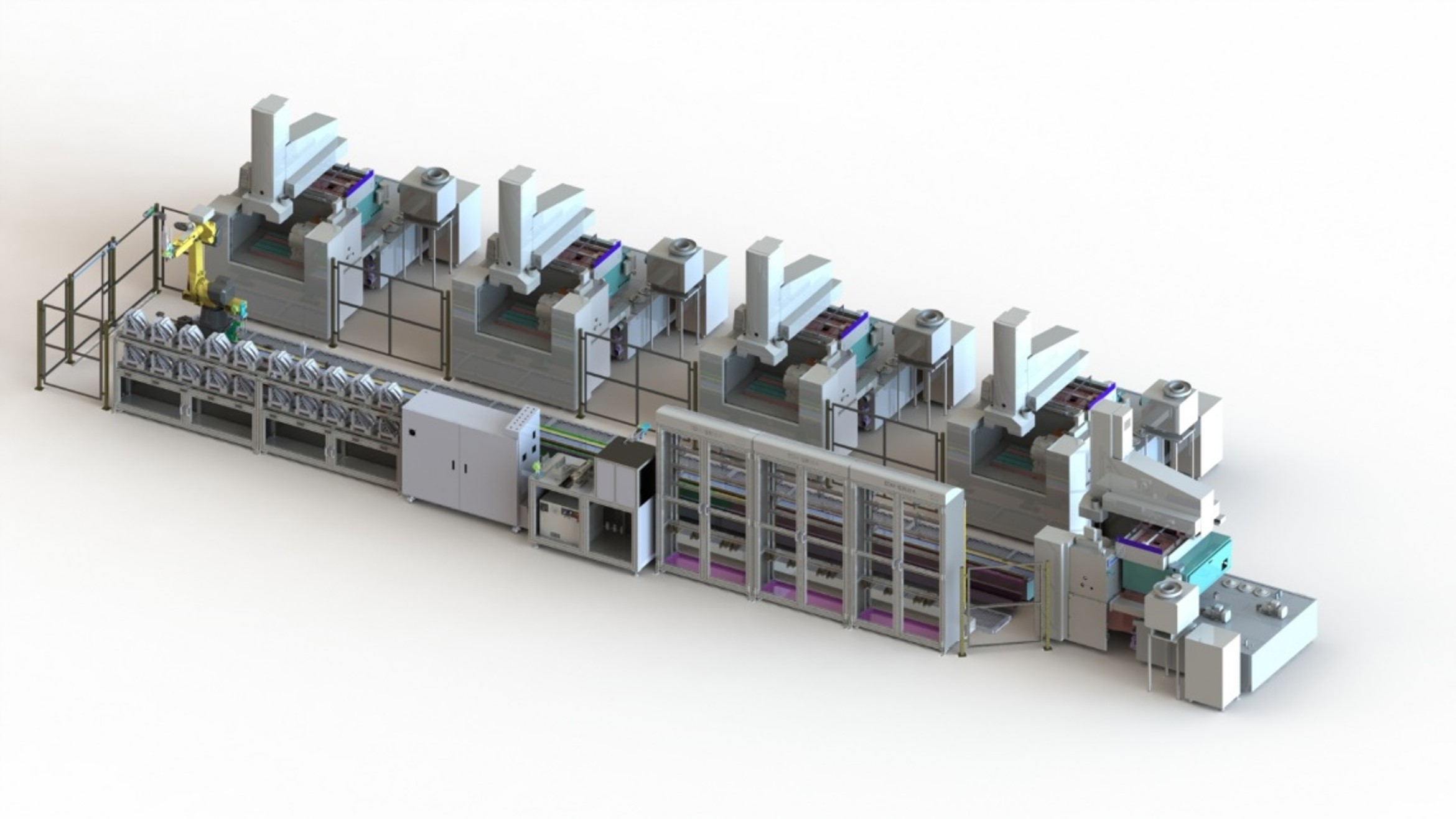

Quick Integration

EX/EXD Series electrical discharge

machine, capable of easy integrated with

MES system, online measurement,

storage system and etc via OPCUA, API.

Smart Production line

Actual application on automobile moulding industry in

Europe. EX series sinker EDM integrated with MES and

milling machine where perform the production just-intime

without any interruption. By increasing 30% of

overall equipment effectivenss (OEE), 2 EDM will then

bring out extra 3,000 hours working time per year