Theme

Digital Transformation

Green Transformation

HAINBUCH GmbH

Product Description :

Ideal for today's high paced manufacturing environment!

Convenient, that the HAINBUCH quick change-over systems fit on all your machines. Even better, that you can change your clamping devices in a matter of minutes, thus earning money quicker and allowing you to manufacture job-oriented. And, thanks to our unique technology, you will achieve a repeatability of ≤ 0.003 mm on the interface.

However, our high-speed solutions have even more to offer: As you will experience shorter machine downtimes along with reduced processing and throughput times,

your quick change-over systems will pay off in no time. Better yet, you will not have to compromise on quality, rigidity or precision.

Select the spindle connection and the clamping device that is right for you from our extensive assortment. We can even accommodate you if you are already using clamping devices made by other manufacturers. We will simply adapt them to our interface.

CHIN MING PRECISION TOOLS CO., LTD.

Product Description :

★ Single Crystal Diamond(Ultra Precision Cutting):

【CVD- HV8,000 ~ 10,000】

【MCD- HV5,000 ~ 10,000】

Work Material:Ceramic, Gold / Silver / Aluminum / Copper / Zinc / Magnesium Alloy, Titanium Alloy, Graphite, Carbon Fiber / Glass Fiber, Wood, Bakelite, Acrylic, Stone, Electroless Nickel, Carbide.

★ Polycrystalline Compound Diamond【HV6,500 ~ 8,000】:

Work Material:Ceramic, Aluminum / Copper, Titanium Alloy, Graphite, Carbon Fiber / Glass Fiber, Wood, Bakelite, Acrylic, Stone, Carbide.

★ Polycrystalline Cubic Boron Nitride【HV3,000 ~ 5,000】:

Work Material:Hardened Steel(HRC45~65°), Powder Metallurgy.

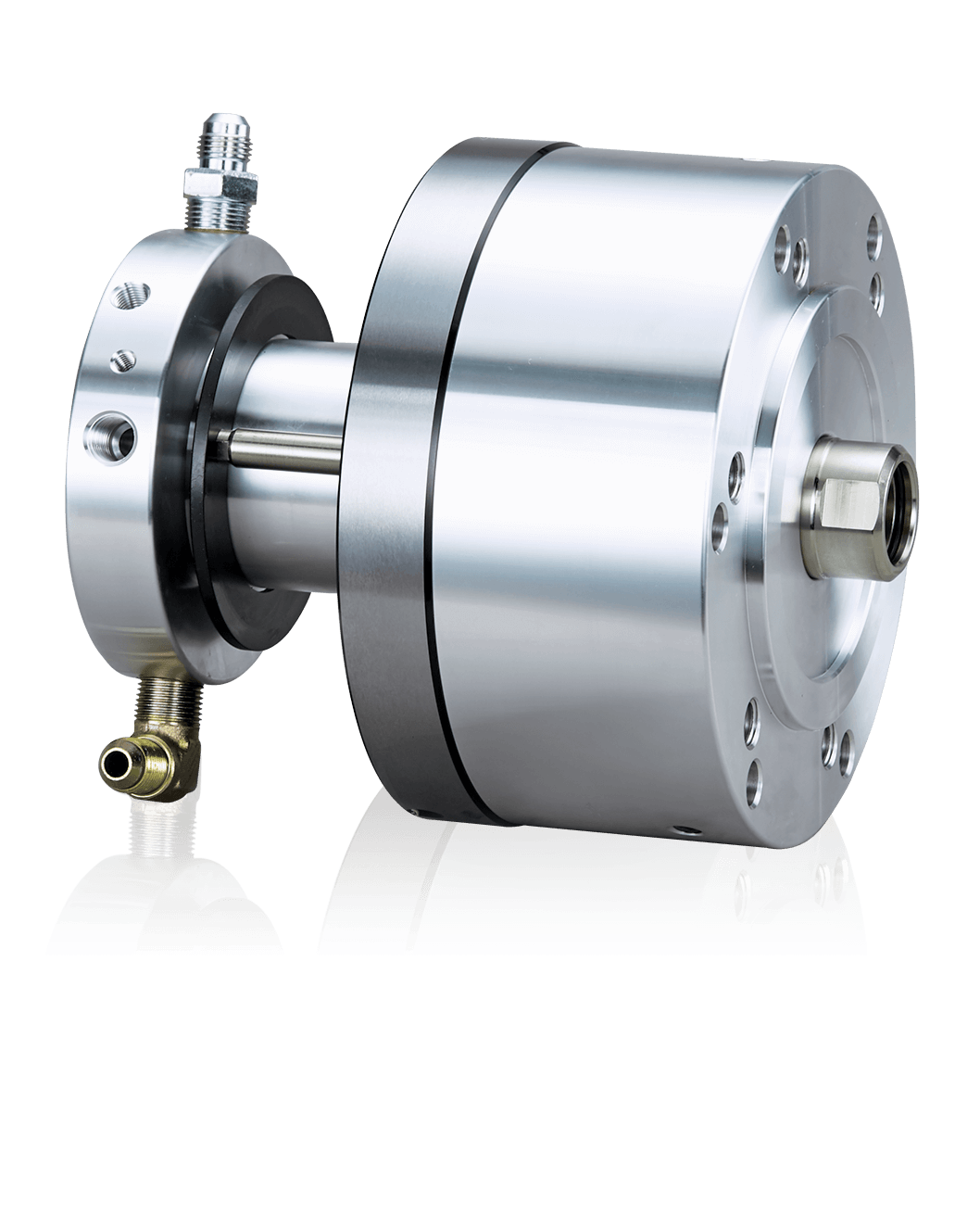

PRECISION MOTION INDUSTRIES, INC.

Product Description :

To solve the problem of reducing the mechanism which use one bearing to replace two bearing solution.

PMI’s designs and manufactures a variety of cross roller bearings that can handle radial, thrust and moment loads at the same time. These compact bearing feature rollers crossed at right angles between inner and outer rings. This structure can reduce the

combined height required for bearings, achieving high rigidity and excellent load capacity. There are currently Standard type CRB, Mounting Holed type CRBF, Robots Installation type CRBR and Customization type CRBX for choose.

TAIWAN FANUC CORPORATION

Product Description :

Lathe chips entanglement has always been the biggest subject of automation.

Entanglement can cause problems such as suspension, failure, and workpiece defects on the machine.

The servo learning oscillation function can effectively solve the chips entanglement problem, minimize the chips and realize the realm of automation.

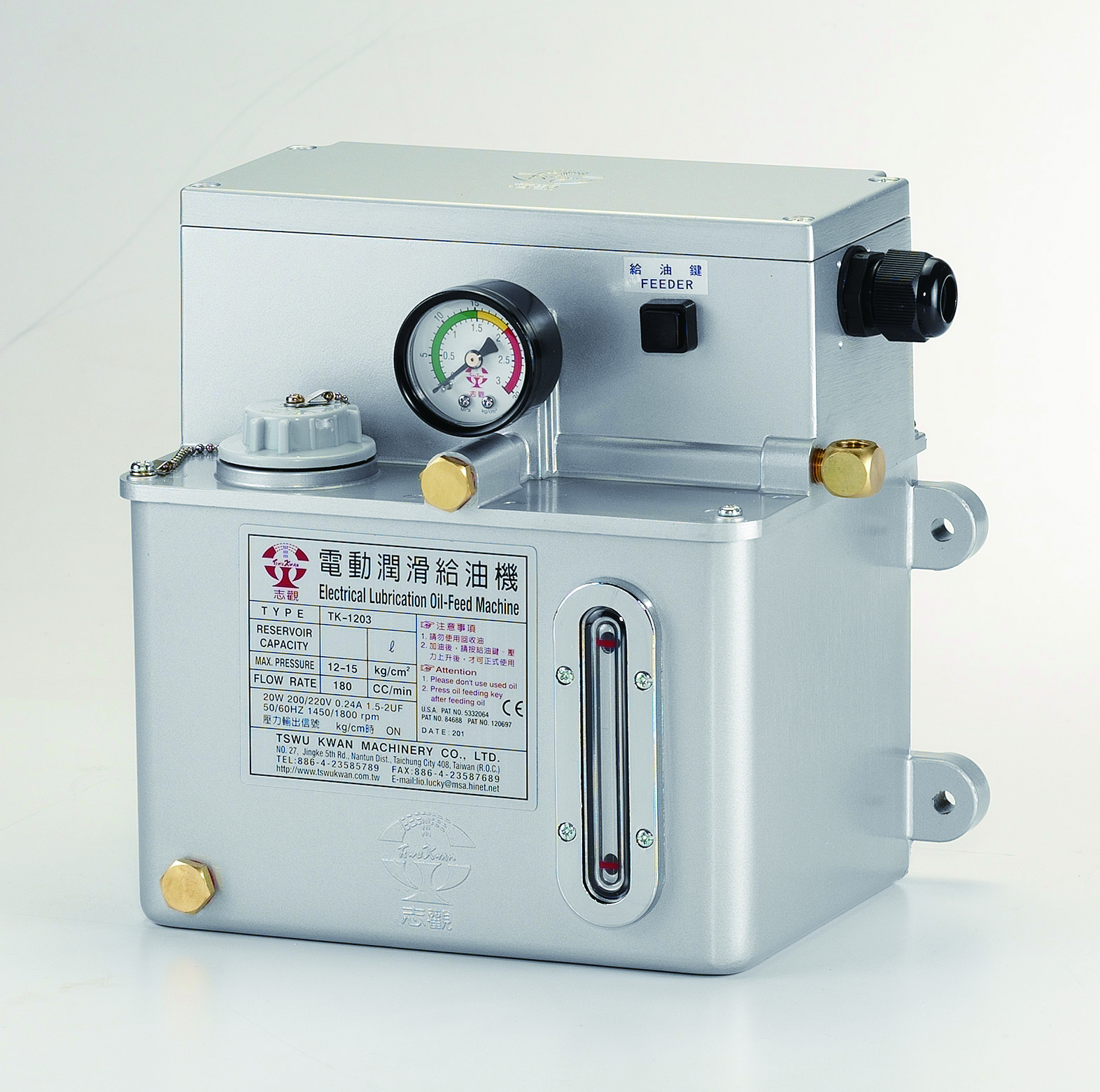

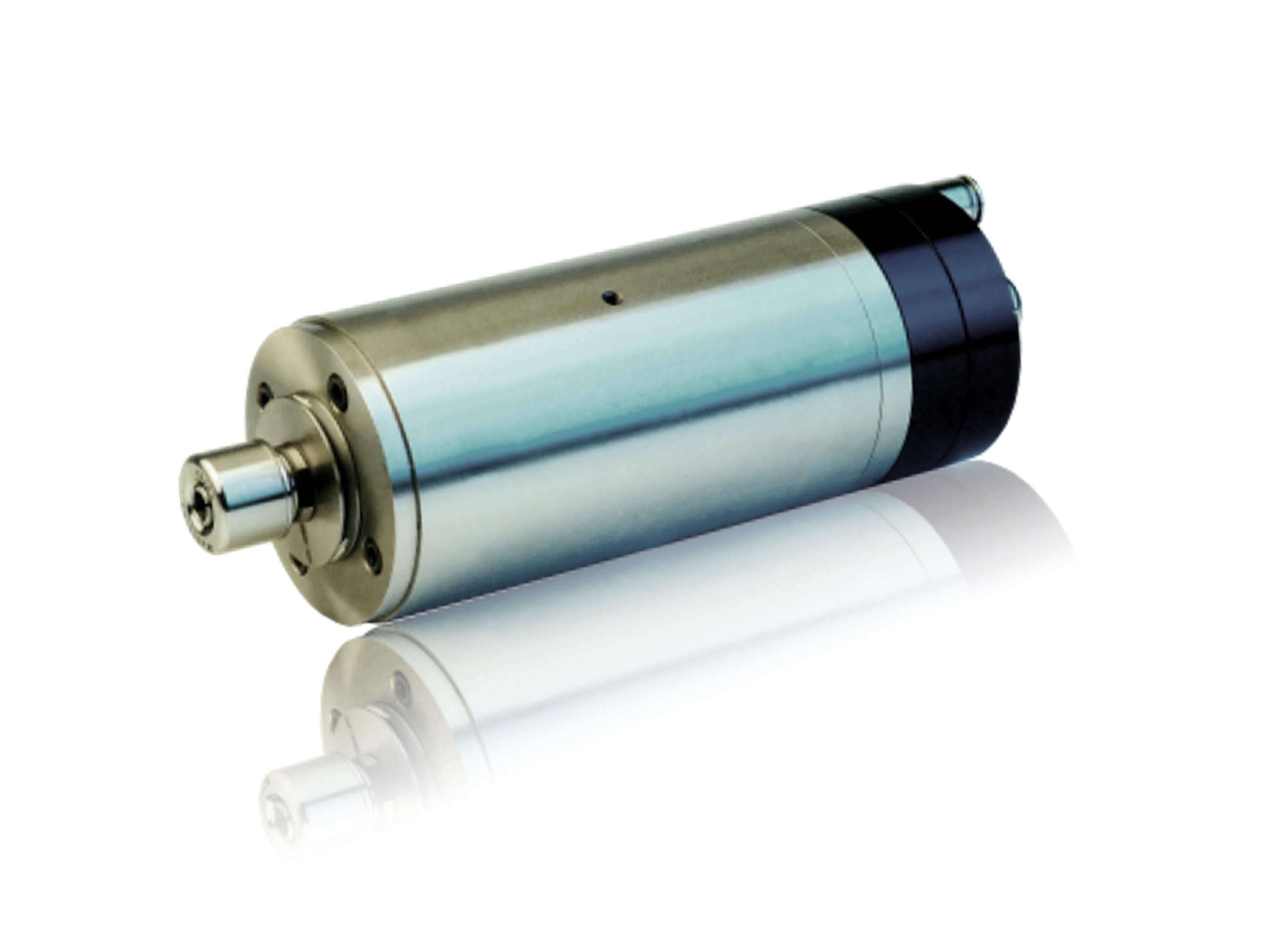

PINTAI MACHINERY CO., LTD.

Product Description :

● NC控制器配合彩色觸控螢幕,機器操控簡易<br />

● 三爪式夾持工件,夾持穩固,進給快速<br />

● 穩重的機體結構,具有最佳研磨穩定性<br />

● X,Y軸自動進給,採用伺服馬達驅動<br />

● 砂輪主軸及工件主軸均可無段變速<br />

● 砂輪主軸轉速50000 rpm<br />

● 高速砂輪主軸轉速,大幅提升加工效率,且研磨面精緻<br />

● 雙V型滑道,經熱處理硬化,滑道面經精密研磨,並貼附Turcite-B耐磨片及鏟花處理<br />

● 附三色警示燈,呈現機台操作狀態

RAISE PRECISION CO., LTD.

Product Description :

CAPTRON is an experienced measuring technology manufacturer for the industry and the market leader in fill level measurement in the field of dispensing technology. Capacitive CAPTRON probes accurately and reliable measure the fill levels of liquids, bulky goods, pastes, adhesives and chemically aggressive materials.

With the CAPselect system for level sensors, you are able to freely configure the probe of your choice depending on the application, container type and sensor properties. CAPTRON produces these with millimetre accuracy to ensure full flexibility.

There are two systems to choose from: Compact probes, in which the electronics and probe form a single unit. Probes with external amplifiers that are suitable for applications with high temperatures and pressures.

Thanks to their wear-free electronics combined with high-quality material such as stainless steel, Teflon and Peek, CAPTRON level sensors are reliable, robust and long-lasting.

CHIEN CHENS MACHINERY CO., LTD.

Product Description :

Specification

Table size: 2600 x 650 mm

Longitudinal travel: 2400 mm

Cross travel: 800 mm

Y slide way width: 1980 mm

Z Slide high: MAX 800 mm

Z Slide way width: 500 mm

Spindle taper: NT#50(BT)

Spindle motor: 7.5HP / 4P

Spindle speed: 70~1200 RPM

Feeding speed: 10~6000 mm/min

Ballscrew: Ø40 mm P=8 C3

Net weight: 6800 kgs