Theme

Digital Transformation

Green Transformation

ICOP Technology Inc.

Product Description :

The QEC-M series is an EtherCAT master that uses a dual-core, independently operating DM&P Vortex86EX2 processor for real-time, reliable synchronous EtherCAT control. The master core of the processor serves as the Arduino development environment; the slave core of the processor serves as the Real-time EtherCAT master. The two cores exchange data via Inter-Processors Communications (IPC).

GUEY CHERNG TRADING CO., LTD.

Product Description :

SIMPLE

Tool is clamped in 8 seconds by pushing

only one single button.

SAFE

No heat up – high clamping force. Excellent vibration dampening.

HIGH PRECISION

Toolholder runout TIR ≤ 1 μm

Total system runout TIR ≤3 µm at 3 x D.

powRgrip®

The tool clamping system of today and the future.

ASMITH MANUFACTURING COMPANY

Product Description :

★Handle: FRP has high stiffness and high loading. Load capacity 60 kgf, it is very light and an insulator to electronics. Users will not be frostbitten when the operating temperature is frozen.

Holder: The hole pitch can be adjustable within 18mm, easy to install. Waterproof (IP66). Working temperature is -20℃~150℃, resistance to acid, alkali, and greasiness.

Two ways for install: 1. Inner stationary type. 2. Outside stationary type.

In accordance with RoHS.

➤Material-Handle : Fibre-reinforced plastic(FRP), Black or Silver

➤Material-Holder : Polyamide(PA6-GF33), Black or Silver.

RAISE PRECISION CO., LTD.

Product Description :

CAPTRON is an experienced measuring technology manufacturer for the industry and the market leader in fill level measurement in the field of dispensing technology. Capacitive CAPTRON probes accurately and reliable measure the fill levels of liquids, bulky goods, pastes, adhesives and chemically aggressive materials.

With the CAPselect system for level sensors, you are able to freely configure the probe of your choice depending on the application, container type and sensor properties. CAPTRON produces these with millimetre accuracy to ensure full flexibility.

There are two systems to choose from: Compact probes, in which the electronics and probe form a single unit. Probes with external amplifiers that are suitable for applications with high temperatures and pressures.

Thanks to their wear-free electronics combined with high-quality material such as stainless steel, Teflon and Peek, CAPTRON level sensors are reliable, robust and long-lasting.

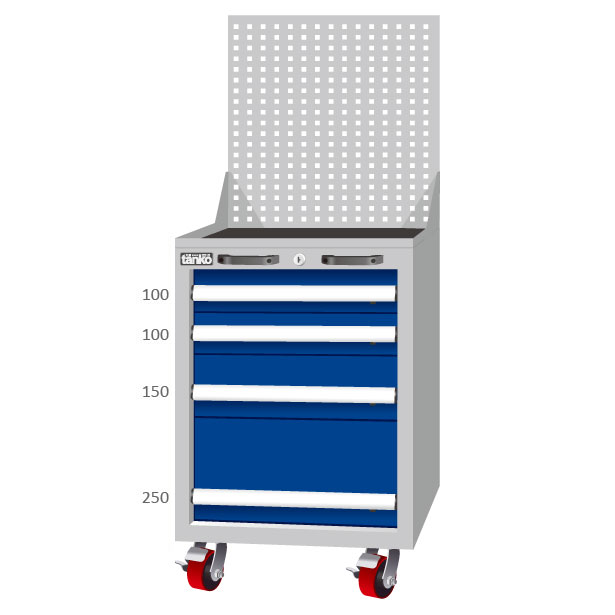

TANKO ENTERPRISE CO., LTD

Product Description :

► Hooks can be applied to perforated boards

► 4"x2" PU casters with total 1000kg loading capacity

► Normal Drawer: 90% extension with 100kg loading capacity

► Special bearing slides system gives you durable and reliable performance

► With striped rubber mat

► 1st drawer with division boxes, the rest with dividers

► Division boxes are suitable for storing small parts

► Adjustable dividers

► Full length aluminum handles with patented safety lock system

► Interlock system

HAWE Hydraulik Singapore Pte. Ltd. Taiwan Branch

Product Description :

Compact hydraulic power packs are a type of hydraulic power pack. They arecharacterised by a highly compact design, since the motor shaft of the electric drive also acts as the pump shaft. Compact hydraulic power packs are designed to supply hydraulic circuits with hydraulic fluid.

The compact hydraulic power pack type INKA consists of the tank, the integrated motor and the radial piston pump or gear pump directly attached to the motor

shaft. The directly mounted electronic communication box with integrated realtime operating system allows the operating state to be recorded and visualised. The

measured values of the integrated multi-sensor (including the motor speed) can be passed on to the higher-level machine controls via standardised interfaces and processed there.

The consistently modular design of the type INKA means that different usage volumes and delivery flows can be realised quickly and easily from the modular

system. Compatible, ready-for-connection, complete solutions can be assembled easily using a wide range of connection blocks and the valve banks that can be combined with them.

Features and benefits

■ Prepared for condition monitoring with integrated sensors and communication box

■ Optimum efficiency through under-oil motor cooling, direct power transmission,and sophisticated heat dissipation

■ Suitable for nominal operating modes S2 (short period operation) and S3 (periodic intermittent operation)

■ Resource-saving due to small oil filling volume

Intended applications

■ Machine tools and material testing

■ Hydraulic tools

■ Handling systems

■ Presses and processing machines

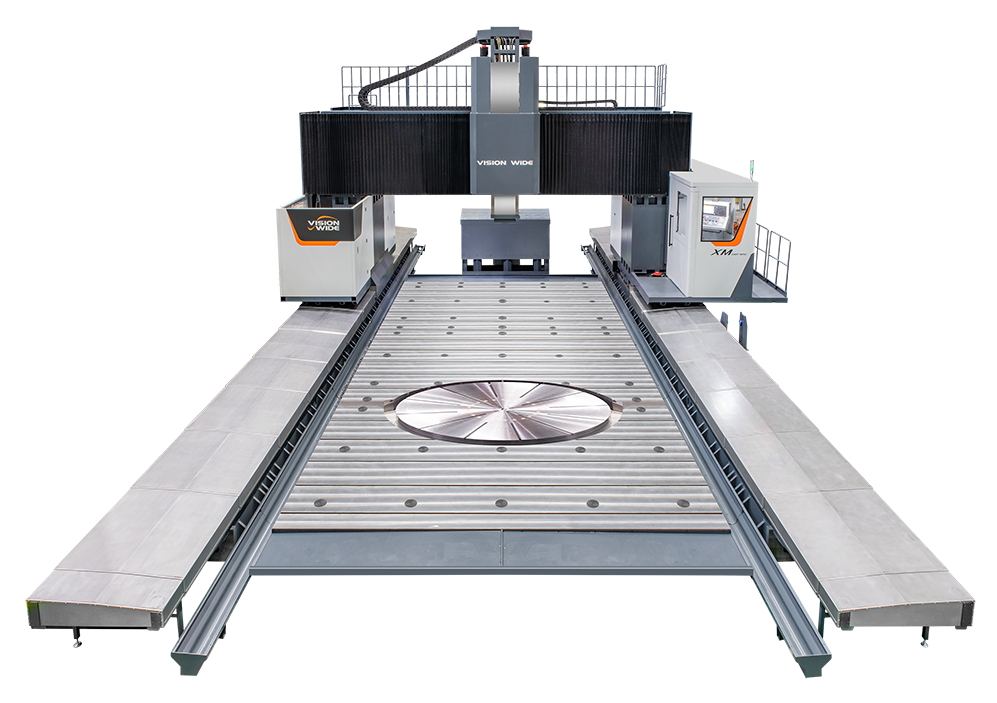

VISION WIDE TECH CO., LTD.

Product Description :

High Performance and Wide Application

XM series moving column machining center is a product developed for the machining needs of large-scale precision machinery, electric power, wind power, energy, petrochemical, transportation... and other equipment. It has:

Huge workpiece machining space: For precision machining of various types of structural parts, it can provide super large XYZ axis machining space.

• High-precise positioning: The high-standard geometric accuracy and positioning accuracy capabilities of the whole machine enable large-scale precision machining

• Heavy cutting capacity: Provide a variety of high-rated torque spindles to meet the processing and cutting capabilities of various materials.

• Fully automatic multi-face machining: This moving column machining center can be matched with various automatic attachment heads for high tangential speed mold surface machining and various types of precision parts complex angle machining, with excellent tool tip point error automatic correction function, and automatic additional head and tool exchange function, it can realize fully automatic machining performance.

• Milling and turning compound multitask: This moving column cnc milling machine can be equipped with a high-torque and high-speed vertical turning table to realize milling and turning compound automatic machining.