Theme

Digital Transformation

Green Transformation

LEADWELL CNC MACHINES MFG., CORP.

Product Description :

The multi-function machine with B-axis can easy have bevel angle drilling and cutting work. The best torque is 3000Nm, and with curved coupling, it can easily do a heavy cutting job shop work and also curved surface milling. The machine uses special Electro Spindle, which can reach 12000rpm, it is a special machine can do a first mill and end mill in the same machine. The Y-axis design is a perpendicular type, and match with our moving column machine structure, the Y-axis have complete movement. It will not have dead space for the travel. (Y-axis travel /-130mm).

Max. swing: 750 mm

Max. turning diameter: 670 mm

Max. turning length: 1700 mm

Bar capacity: 78 mm

X-axis travel: 600+50 mm

Y-axis travel: ±130 mm

Z1-axis travel: 1750 mm

Z2-axis travel: 1725 mm

B-axis angular stroke: 240°(-30°~+210°) mm

Spindle speed(chuck): 3500 rpm

Spindle nose(chuck): A2-8/10"

Spindle speed(electro): 12000 rpm

X/Y/Z1/Z2-axis rapid traverse: 30/24/30/30 m/min

Tool storage capacity: 40 T

HO CHEN MACHINERY & ELECTRIC IND. CO., LTD.

Product Description :

XYZ axes travel: 500x400x185mm (20"x16"x7") inch

U axis travel: 300mm (12") inch

Z axis single travel: 400 mm (16") inch

Work table: 800x450 mm (31"x18") inch

Max. Workpiece: 1250x650x390 mm (49"x26"x15") inch

Max. Workpiece weight: 1400 kg

Max. Electrode weight: 185 kg

Machine net weight: 2100 kg

Oil level: 110-360 mm (4"-14") inch

Packing Size(LxWxH):2340x2320x2500 mm (92"x91"x98") inch

Work Table to platen:

1. Z axis single travel: 230-630 mm (9"x25") inch

2. UZ axis: 230-715 mm (9"x28") inch

Filter: 1

Paper filter:2

Capacity:550 Liters

Machine Features

> Windows CE controller

> A dialog window with picture description.

> Special repaired frames to quicken the maintenance speed.

> Close-loop design of digital feedback on three axes of the machine significantly increases positioning precision and ORBIT-CUT machining accuracy and efficiency.

> Simple operation interface.

> Common function keys are located on the operational panel for direct use.

> Hot key setting.

> ATC (automatic tool change) and C-axis 360° index can be installed; the process of coarse machining to ultra-fine machining can be completed at one time.

> Dialogue diagram provides various hole-expanding modes such as quick search of edge, centers and datum marks.

> Rich color graphic (the same resolution as a PC screen).

> Automatic multi-step machining (coarse, medium coarse, medium fine, fine, superfine)—up to 10 steps.

> Unlimited number of machining conditions can be saved as machining archives. Each set of machining conditions can be edited, modified or stored. They are easy to edit and easy to find.

> Automatic origin search and multi-point coordinate memory capability.

> 1/2 design capability, ARC automatic discharge waveform detection and automatic adjustment.

> Automatic center position detection, automatic compensation, search of hole center and deepest point; fixed hole machining (cyclic mode, independent mode), which is suitable for different machining conditions; Radial, circular, square, linear (vector), coning, 45° hole-expanding machining.

> Three-axis beeline, two-axis arc, three-axis helix.

> Chinese/English versions interface, metric/British system switch and Z-axis quick up, quick down, slow up and slow down capability.

> Lateral machining, three axes, six directions (plane rotation).

> All alarms describe the source, date and exact time of problem occurrence.

> Optical scale is applied for close-loop position control, enabling extreme position for machining.

> Automatic editing—settings can be done according to type of material, work piece size, machining depth, one side die clearance, final current and rate of electrode wear.

> CNC models possess conventional capability of consistent level of energy discharge, achieving stable and rapid machining and smooth high quality on machining surface while the rate of electrode wear is still low.

> Monitor page indicates machining path and orbital pattern in use.

PHD Books Co., Ltd.

Product Description :

機械雜誌的第一品牌

充滿未來性之「機械新刊」具備三點特色:

第一,「選對的主題」。機械新刊每月所挑選的文章,都是對機械產業非常重要的指標性主題,多元化的內容整合,適合讀者每月翻看,汲取新知。

第二,「用對的人」。機械新刊之主編群結合產、官、學、研各界專家菁英,提供最優值的文章和綿密的產業資訊。現在是知識經濟的時代,在知識情商方面,哪一家公司有新產品?哪一家公司有好技術?透過機械新刊廣大的客戶產品資訊,讓您在通路行銷,研發製造各方面都能領先群倫。

第三,「做對的事」。機械新刊的市場定位及聚焦策略,考量傳承與創新之間的平衡,希望雜誌內容能兼顧廣度與深度,除了持續保持專業文章的深度,更重要是與市場貼近,完全掌握市場脈動,同時加入人文的溫度。

2017年起,博士文創事業經營機械新刊,以「廣遞新知,用心規劃」為宗旨,努力建立遍及海內外的讀者群。我們計畫以台灣為中心,向海外拓及讀者群,讓所有華語專業人士,都能翻閱機械新刊,從中獲得想要的資訊。另外,我們要使刊物成為客戶最佳的行銷利器。我們充分瞭解客戶的需求,讓機械新刊成為情資收集的專業平台,展示產品的最佳舞台。機械新刊紙本刊物搭配電商規劃,讓廠商在數位時代,將有更高更長久的曝光。

機械新刊充滿前景,「選對的主題」、「用對的人」、「做對的事」,我們的團隊專業,充滿競爭力,發行人出身機械產業,親身投入用心經營。機械新刊才剛要開始發光發熱,我們有絕對的信心,成為機械雜誌的第一品牌。

SCN MACHINERY CO., LTD

Product Description :

180°油壓反轉合模機 - SDP series<br />

<br />

Tonnage: 50 - 600 ton<br />

Bolster Area: 1000 x 800 - 4500 x 3000 mm<br />

<br />

龍門型高強性、高精度機身設計,操作簡單的控制系統。<br />

動作精確,機台易操作,可減少勞動者的勞累,提高工作安全。<br />

適用於各類精密成型模具精修。(沖壓模、射出模、鋁壓鑄模)<br />

上模可180°完全翻轉,方便工作人員精修模具。<br />

標準附件:10"LCD觸控螢幕。<br />

符合ISO 9001:2015認證

TES ELECTRICAL ELECTRONIC CORP.

Product Description :

FEATURE:

Compliant with IEC 61672-1 class 1 standard

Dynamic range of 90dB

AC and DC outputs

Data transfer using USB

microSD card

Real-time 1/1-Octave and 1/3-Octave analysis

Measurement can be started by internal or external trigger

Comparator output to trigger external devices

Super high – contrast backlight TFT – LCD color display

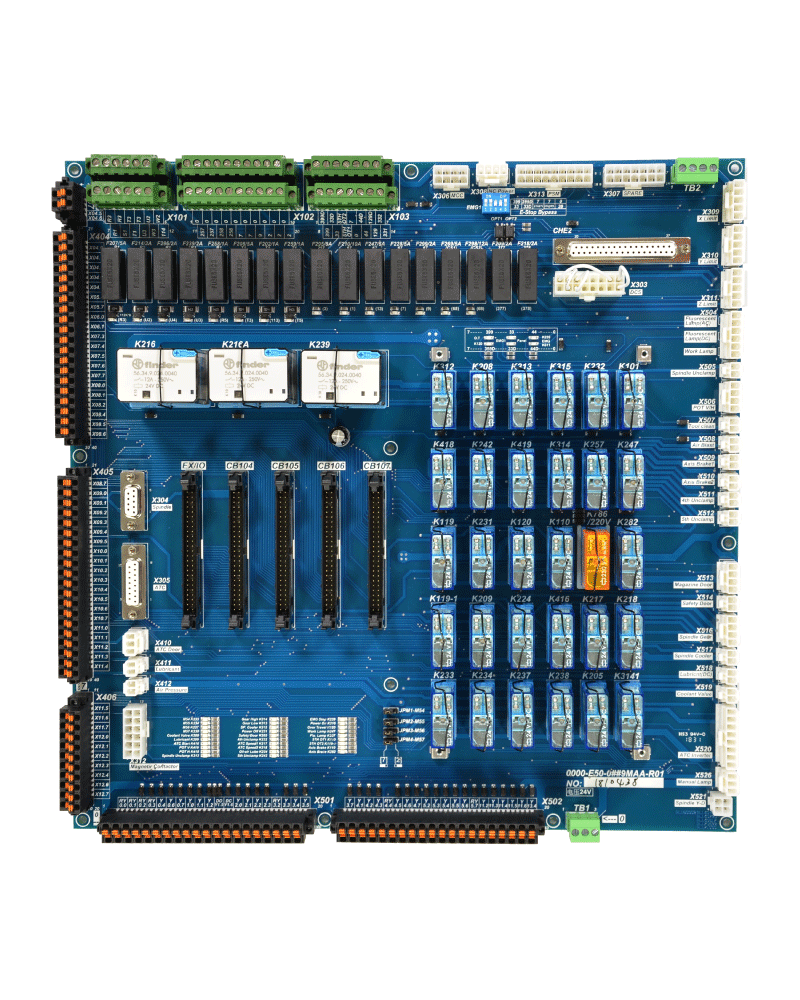

YEU-LIAN ELECTRONICS CO., LTD.

Product Description :

OEM/ODM circuit board combined adapter board, relay board, patch board and I/O board into one piece - all optimized to customers' needs. The PCB circuit board can customize various controllers such as FANUC, MITSUBISHI, SIEMENS, FAGOR, HEIDENHAIN and industrial types. Apply to CNC machines like lathes, milling machines, turning, multitasking machines, machine tools or industrial machinery.