Theme

Digital Transformation

Green Transformation

KAO FONG MACHINERY CO., LTD.

Product Description :

KG series gantry five-sided machining center is able to choose to carry all kinds of automatic additional head (90゜angle milling head, universal head, extension head, speed-up extension head ... etc.) auto tool changer. Standard verticaland horizontal tool changer magazine tool with optional multi-head library for automatic head exchange. Angle head part has 5° division curved tooth with standard high precision, and are able to select 1/2.5°division or watering function at the center. KG5A series bridge crane five-axis machining center is mainly designed for the processing demand on medium and large weight workpieceparts, with world-class high-quality five-axis manufacturing technology to complete the five-axis processing, it synchronously completes vertical, horizontal and a variety of free angle of processings, which substantially increases the processing efficiency. Floor-type workbench with super load capacity, up to 2.5 tonsweight per square meter. Adopting HSK-A63 24,000 rpm high-speed spindle or the heavy cutting spindlewithHSK-A100 10,000 rpm high-torque output depends on different maching applications, which greatly improves the processing efficiency of large workpiece, and fully meets the processing needs of different industries.

MING YANG MACHINERY CO., LTD.

Product Description :

This multi-tasking turning center is an advanced machine designed to process precision complex parts in one setup.

Power & Versatility: It has Double Spindles, a VDI/BMT 12 station Turret and a 2nd Y-Axis for back machining with 14 tools for a total capacity of up to 38 tools. This solution with superimposed cutting is a powerful combination of precision and two Y-axes for machining of complex workpieces with extremely fast cycle times.

Front Machining: BMT45 12-Stations, Up to 24 tools, 7.5/11 kW Spindle Power, 55 mm Through Hole.

Back Machining: Gang Tools Slide: 14 Tools, 3 Cross Live Tools, 3 Face Live Tools, 3 OD & 5 ID Tools.

BENIGN ENTERPRISE CO., LTD.

Product Description :

• Heavy duty mill for wide range of applications

• Machine body is made of Meehanite casting.

• 5 HP inverter driven spindle, variable speeds

• X & Y axes automatic feeds driven by 1⁄2HP 12P motor and inverter

• Z axis rapid up-down driven by 1⁄2HP 6P motor.

• ISO 40 spindle, quill diameter 105mm

• Y & Z axes square ways

• Turcite-B coated on X & Y saddle.

• Hardened table and all slide ways.

AUTOCLAWS PRECISION MACHINERY CO., LTD.

Product Description :

1. Suitable for round-bar shape objects to clamp before cutting process.

2.Using the advanced high-strength alloy steel, the key components have been treated with hardening which is strengthening the structure and enhancing the stability with accuracy and durability.

3.Large caliber design allowing the bar material go through, furthermore, it can be complemented to automatic processing eqipment for enhancing the machining efficiency.

4. The chucks complement the rotary hydraulic cylinder to provide a stable pressure for various chucking conditions.

5. Professional precision grinding makes it high-precision, precision repeat clamping accuracy, high clamping force.

KING NICE TECH.CO., LTD.

Product Description :

▎Liquid filter purification, easy removal.

▎ Patented technology - easily correspond with liquid,water-soluble and Pure-oil Auto.

▎ Processing can easily recover swarf and sediment without stopping.

▎ The highest filtration accuracy can correspond to 5 nano.

▎ Solve the problem of long-term deposit on CNC water tanks such as iron chips,aluminum powder,fine sediment,etc.after machining.

▎ Widely used in metal cutting, aluminum machining,grinding process,engineering plastics, etc.

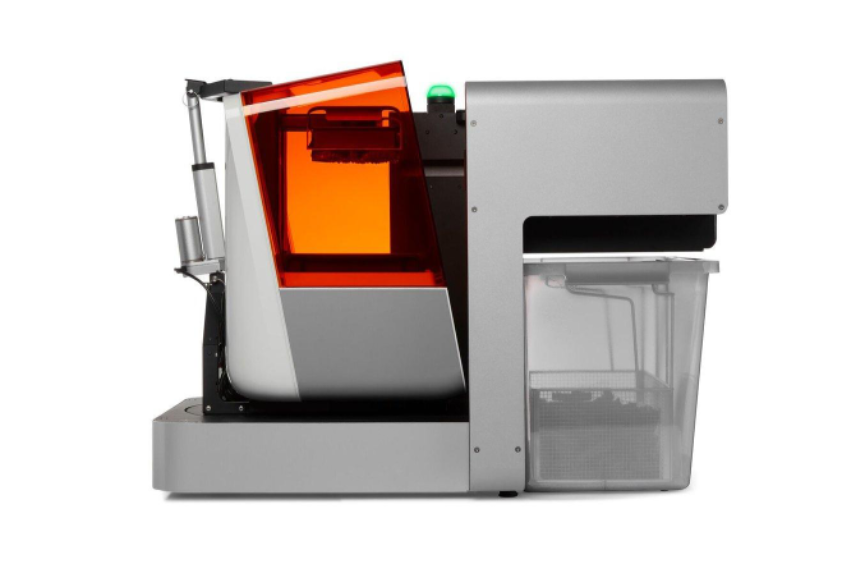

Taiwan TeamA Tech. Co., Ltd.

Product Description :

擺脫時間、地點的限制,利用自動化生產解決方案再創生產率新高!無需人工操作,24小時不停機生產,製造大量、高質量物件,使用 Formlabs 自動化解決方案(包含 Form Auto、群機管理和高容量樹脂系統),在 3D 列印工作流程中更高效的工作並重新定義生產能力。在不增加列印機管理複雜性的情況下擴展您的零件生產。從任何地方點擊發送,Formlabs 自動化解決方案將處理剩下的工作流程。

【最大程度地降低每個零件的成本,節省高達 80% 的勞動力】

在 Form Auto 出現之前,每個完成的零件都需要在後處理之前從成型平台上手動移除。Form Auto 透過將 Formlabs 獲得專利的「快速剝離技術」與「成型平台 V2 」結合使用,完全自動化地移除零件。蒐集的零件被放置在防紫外線的容器中,無縫批量轉移到 Form Wash。

【24 小時不間斷 3D 列印,無需額外程序】

Form Auto 自動化生產系統旨在不閒置列印機、不讓列印物件在序列中等待,無論現場是否有操作人雃,Form Auto 始終準備好開始下一次列印。 隨時隨地構建多列印機群,從辦公室點擊「列印」,立即在生產間開始生產。透過群機管理中的圖像和影片遠程監控和審查成品零件,設備內相機在完成時捕獲每個列印件來保存每個部分的記錄。