Theme

Digital Transformation

Green Transformation

FINTEK INDUSTRY COMPANY LIMITED

Product Description :

Initial pinch 3-Roll plate bending machine

Affordable single pinch bending application, flexible use of small space workshop

3 rolls camber designed with hardness HRC 50-53 degrees, dealing with various material processing

Build in high quality hydraulic system with overload protection

The first choice for petty workshops or personal studio, small invest and fast get back

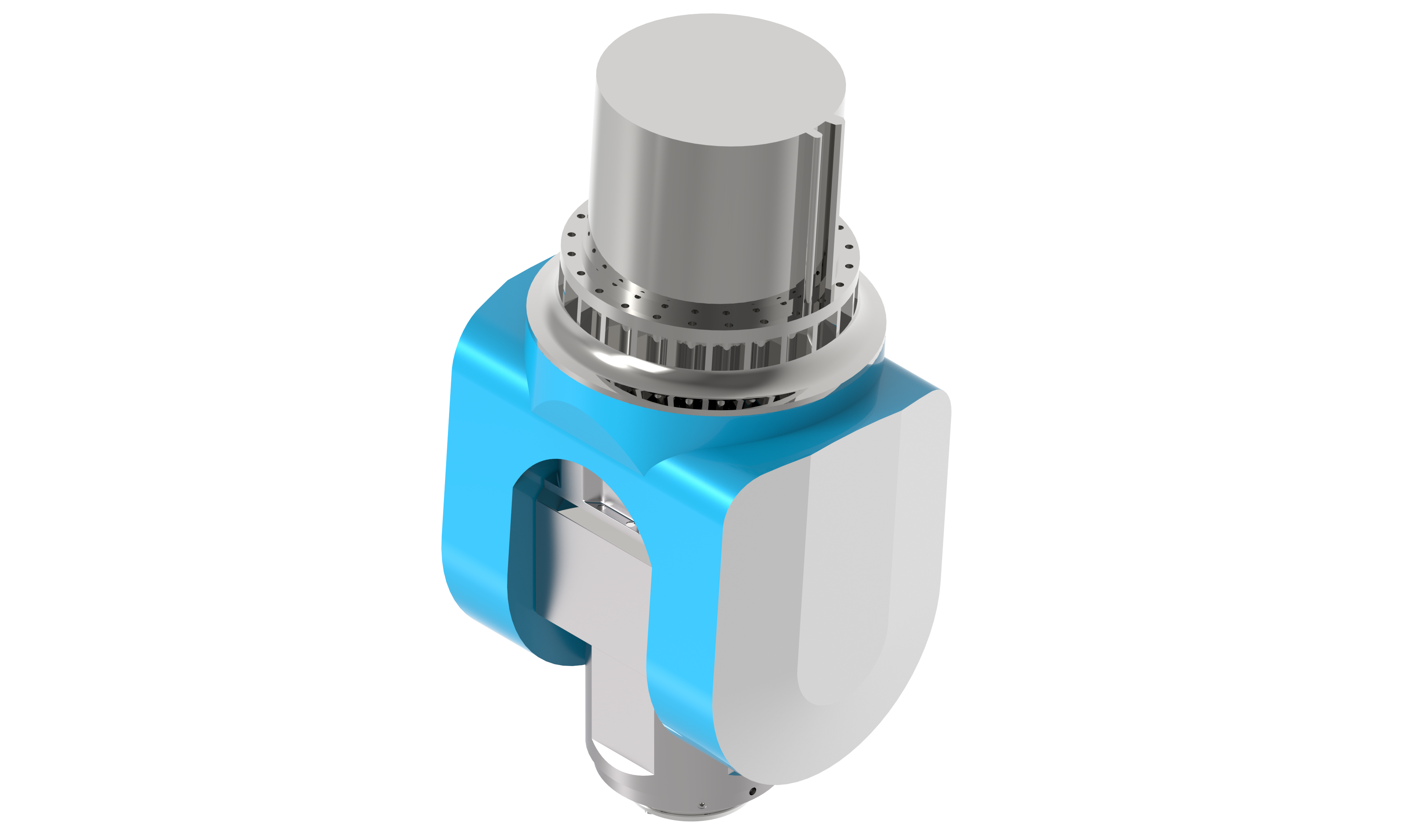

GP MACHINERY CO., LTD.

Product Description :

AREA OF USE:

Processing structural components for trains and the air and space travel industries

Construction of models and prototypes

Design

RAW MATERIALS AND PROCESSING:

Finishing steel and cast iron

Roughing aluminium, Zamac, CFRP/GFRP

Artificial materials, wood and ureol

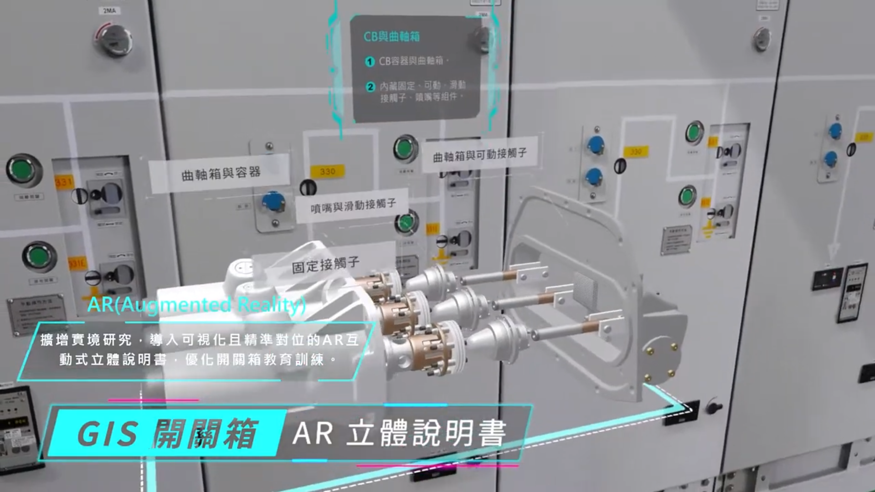

Administration for Digital Industries, moda

Product Description :

The Industrial XR SOP Solution""utilizes AR/VR/MR cross-platform integration technology to ensure seamless operation across various devices such as smartphones and head-mounted displays. It is specifically designed for the industrial sector as an XR intelligent carbon reduction integration platform service.

It's key features include support for ""cross-temporal"" information transmission and real-time monitoring, enabling precise and instant ""cross-span"" collaboration capabilities. Through the integration of virtual and augmented reality, information is transformed into a ""visualized"" presentation, allowing users to intuitively understand and operate, thereby assisting enterprises in effective resource management, reducing waste, and helping industrial production lines lower carbon footprints. This, in turn, improves energy efficiency and achieves a more environmentally friendly production model.

The application scope covers various stages of industrial production, including machine equipment, factory premises, vocational training, remote collaboration, maintenance and operation, and business showcases. Through comprehensive cross-platform integration technology, it provides intelligent, efficient, and eco-friendly solutions.

CHIN MING PRECISION TOOLS CO., LTD.

Product Description :

★ Single Crystal Diamond(Ultra Precision Cutting):

【CVD- HV8,000 ~ 10,000】

【MCD- HV5,000 ~ 10,000】

Work Material:Ceramic, Gold / Silver / Aluminum / Copper / Zinc / Magnesium Alloy, Titanium Alloy, Graphite, Carbon Fiber / Glass Fiber, Wood, Bakelite, Acrylic, Stone, Electroless Nickel, Carbide.

★ Polycrystalline Compound Diamond【HV6,500 ~ 8,000】:

Work Material:Ceramic, Aluminum / Copper, Titanium Alloy, Graphite, Carbon Fiber / Glass Fiber, Wood, Bakelite, Acrylic, Stone, Carbide.

★ Polycrystalline Cubic Boron Nitride【HV3,000 ~ 5,000】:

Work Material:Hardened Steel(HRC45~65°), Powder Metallurgy.