Theme

Digital Transformation

Green Transformation

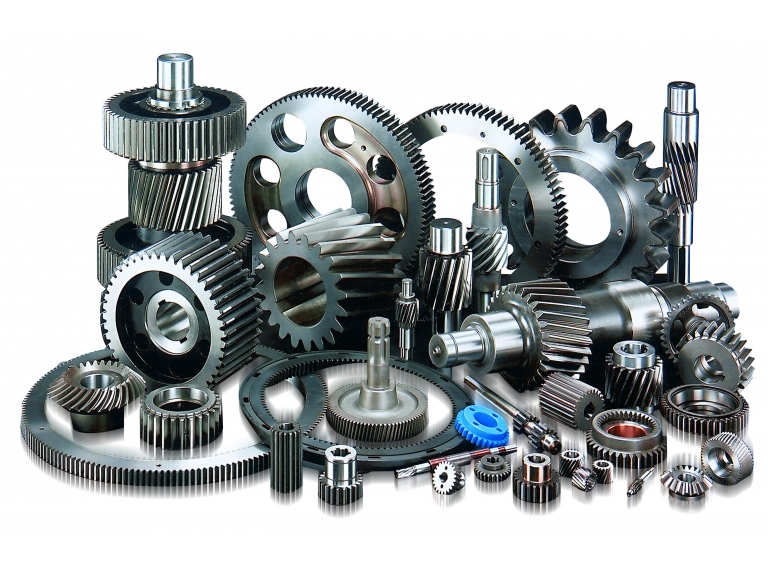

YANMECH Industrial Co., Ltd.

Product Description :

Product Features:Different from the previous positioning of the box jaws by the positioning key, this product will positioning parts into the product, can be locked with the screw lock or unlock, can avoid the traditional positioning the possibility of flying out in the rotation and the advantage of easy assembly.

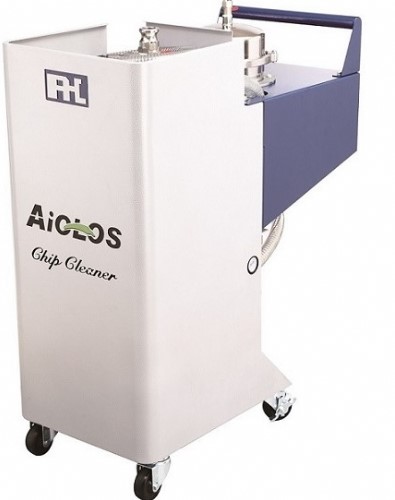

CHING HSYANG MACHINERY INDUSTRY CO., LTD

Product Description :

1. Stable construction, strong rigidity, low vibration and high cutting

accuracy.

2. Floating feeding method makes aluminum extrusion or material with a

little curve feed easily.

3. Extraordinary horsepower design. Horsepower can be adjusted

according to the demand of saw blades. It cuts fast and has great

productivity.

4. Two saw blade lubricating devices for powerful spray cooling and auto

cooling via cooling liquid.

5. Electronic saw blade protection device and automatic saw blade

stopping device ensure operational safety and the smoothness of the

sawed faces.

6. Patent, After cutting, separating work piece before cutting tool moves

backward, machined surface will be shiny without tooling trace, the life

of saw blade is long.

7.Digit display allows for easy, accurate and fast length adjustment.

8. Applicable for sawing and cutting aluminum, aluminum alloy, brass

alloy, brass and plastic.

9. Control knob provides easy central control and operation.

10. Automatic material-absence sensing and stopping device.

11. Can be equipped with a sawdust collector for clean and convenient

sawdust collection.

12. Action as below:

Put into the material, automatic feeding, automatic positioning,

automatic cutting, can be cutting round, square shaped, head material

and tail material are automatically separated.

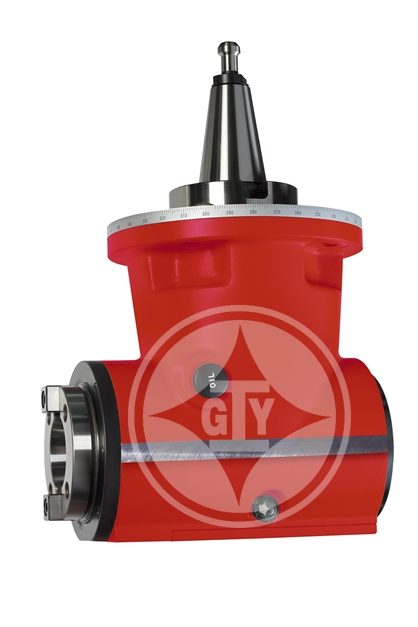

ROYAL PRECISION TOOLS CORPORATION

Product Description :

▶High speed

▶High precision, high efficiency

▶High dynamic rotary accuracy

▶Balancing adjustment within G1, low vibration

▶Modularized easily

▶Thermal displacement, high stability

▶Short overall length, low inertia

▶High motor power, high moments of inertia

▶Applications: Milling, turning, mill-turn, multi-spindle

TAIWAN 3AXLE TECHNOLOGY CO., LTD

Product Description :

Colour Marking Fiber Laser

Marking Machine

Good for metal materials, All polycarbonate material, plastic Stainless steel and other metal materials surface marking.

Laser safty goggles, Simple Fixture, External red light, Foot Switch.

Taiwan laser marking software

Availavle in 9 languages, English, Traditional/Simplified Chinese, German, Japanese, Polish, Portuguese, Turkish, Vietnamese, Portuguese, Turkish, Vietnamese.

Deep engraving, Metal marking, Serial number, QR code, Data matrix all in one machine.

Auto focus up to 4cm.

3D Rotary up 120º degree.

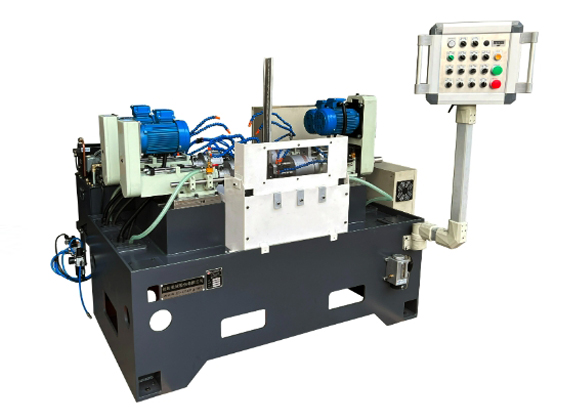

YI CHANG MACHINERY CO., LTD.

Product Description :

Linking a made horizontal Unith drilling machine and tapping machine with a hydraulic sliding table, assemble with an automatic loading and unloading system, enables rapid completion of drilling, tapping, and double-sided chamfering tasks.

This setup saves labor and allows precise control of relative positions.

If you have any thoughts or inquiries about our machine, please leave a comment below or call our company. We look forward to engaging and communicating with you!

OSCAR E.D.M. COMPANY LTD.

Product Description :

1.X and Y sideways with manual handwheels for positioning, servo driven Z axis. COC-280 for orbit function available (option).

2.IPC industrial CPU, color LCD screen.

3.FAGOR linear scale with 0.005mm resolution (standard).

4.C7 ball screw with precisely scraped sideways, self-designed strong heat-treated FC25 casting. In combination with proper maintenance advised by OSCARMAX ensure high accuracy and reliability for decades.

5.V8 Copper and graphite special circuit to increase efficiency and minimize electrode wear-out.

6.TURBO (option) & EZ SPARK (option) - OSCARMAX selt-developed high-speed circuits help to increase efficiency and MRR of standard (TURBO) and super hard (EZ-SPARK) materials, especially for deep ribs and roughing operations.

7.Technologies for sparking steel (SKD11, P20, NAK80, STAVAX, stainless steel), aluminum, tungsten-carbide, titanium, copper, copper alloys and nickel alloys materials using graphite, copper, and tungsten-copper electrodes.

8.Memory for multiple coordinates (100 work-points).

9.DC servo drive with manual fine tuning to maintain process stability and surface integrity.

10.Remote control box for easy operation.

11.FULLY automatic programming.