Theme

Digital Transformation

Green Transformation

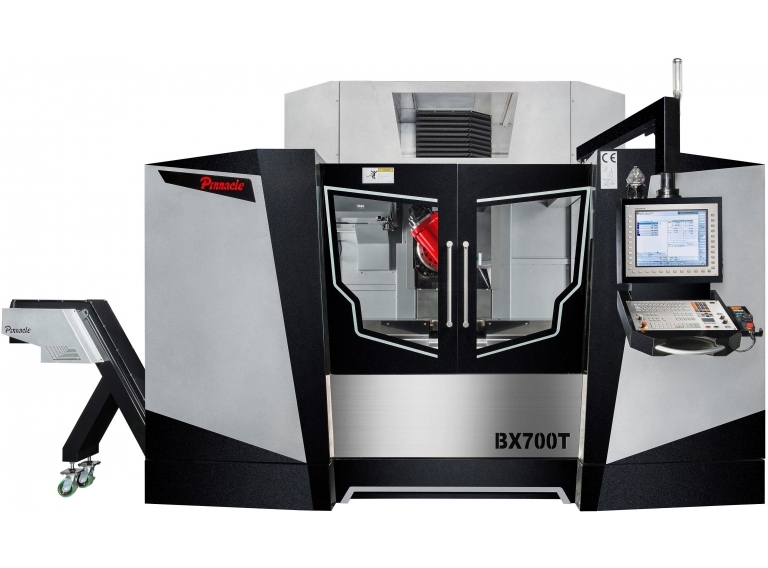

PINNACLE MACHINE TOOL CO., LTD.

Product Description :

2台立式 + 車床? <br />

立式+4軸轉台 + 車床?<br />

5軸機 + 車床?<br />

還在為複雜的工件煩惱買什麼機台嗎? <br />

BX700T絕對是最佳首選! Milling and Turning 銑車複合的五軸加工中心,B軸擺頭+/-120度,搭配內藏式15000轉主軸,內坎式C軸直徑630mm工作台,C軸轉速有800轉及1200轉作選擇。。專利設計,完美結合:最大的加工空間、最小的干涉、高精度及高效率的五軸銑車複合機。一台抵三台,投資成本相對少,佔地空間小。<br />

ZHAO YI HSIN INDUSTRIAL CO., LTD.

Product Description :

Providing clean compressed air without energy consumption

No power required

Applying characteristics of compressed air, hydromechanics and physical principles to design internal structure.

Consumable-free, maintenance-free

Exclusive patented structural design can separate moisture from compressed air without consumables.

Efficiency of air drying and moisture filtration: 99%

Patented high efficiency water-cooled heat exchanger and special air-water separation structure.

High quality, durable, and longevity up to 10 years

No compromise on quality, the product is made in Taiwan.

No electronic and other energy-driven device

Suitable for those who have special needs for compressed air.

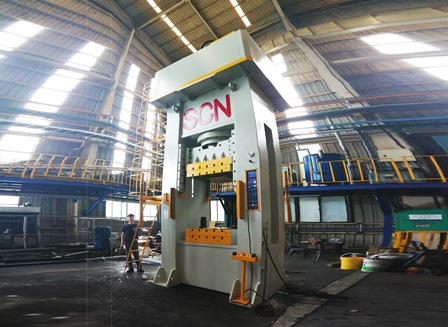

JAR HON MACHINERY CO., LTD.

Product Description :

1.Attached with multi head which can drill many parts at the same time in order to enhance efficiency.

2.Design a complete unit of multi head, guiding hole plate and jig in order to have high accuracy.

3.Suitable for reaming, drilling and chamfering.

4.Optional functions: "Auto. discharging chips" and "Auto. breaking chips".

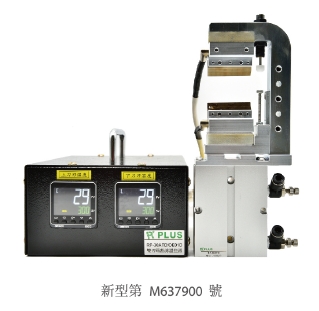

R PLUS TECHNOLOGY CO., LTD

Product Description :

Rplus pneumatic thermal cutters are designed for plastic molding and specified configuration. A designed pair of thermal knifes with a suitable heating rate, the unique design will reduce the heating time and reach the setting temperature in few seconds. The shearing is driven by a dual rod cylinder with 0.15~1Mpa range pressure.

Knifes are made by alloy special steel with heat-treatment. The heating capacity is 150W within 8mmx35mm heating bars , the range is 60~350C. The dual rod cylinder drives the thermal knifes will lead to a stable shearing effect, as well as higher efficiency, reduce the loss, faster shearing and depends on different type of plastic can be set variable heating temperature.

For modern manufacturing, we can integrate on a robot arm and automatically processing line.

Examples of widely application as head lamp of automobile,optical lens, acrylic products and Polycarbonate,etc. We forward to offer a safer , easier and efficiency tools.

GSTC TECHNOLOGY CO., LTD.

Product Description :

HAINBUCH is a German company founded in 1951, specializing in the design and manufacture of high-precision clamping systems and chucks, particularly for demanding CNC machine tools and automated machining industries. The company is renowned for its innovative technology and flexible solutions, supporting various machining processes such as turning, milling, grinding, and drilling.

HAINBUCH’s products emphasize efficiency, precision, and modular design, allowing for quick and easy changes of clamping systems to enhance machining flexibility and production efficiency. Their clamping systems are widely used in various industries, including automotive, aerospace, medical technology, energy, and mold making. Through continuous innovation and the development of high-quality products, HAINBUCH has become one of the global leaders in clamping technology solutions.

TAIWAN 3AXLE TECHNOLOGY CO., LTD

Product Description :

Created to meet the demands of modern welding, MAXWELD combines a stylish appearance with outstanding performance. Focused on space optimization, it makes your workspace more spacious and efficient. MAXWELD is the world's first model to adopt a large-area airflow design, specifically designed for high-temperature environments within factory facilities. This unique airflow design ensures that the equipment maintains effective cooling even under high-temperature conditions. Additionally, MAXWELD comes equipped with dust-proof cotton to effectively prevent dust from entering, ensuring the stable operation and extended lifespan of the equipment.

INNOSERV FA INC. TAICHUNG BRANCH

Product Description :

Micro Dynamics Vertical Machining Center Line opens a new era in multi-purpose and versatile machining centers. Compact, durable, powerful, strong and accurate, the MEGA/TERA Series starts a revolution in the market: the smallest C-frame machines provide powerful and precise results for manufacturers of dies and molds, aerospace, automotive, semi-conductor, job shops and general machine sectors.

The MEGA/TERA Series has been designed with the latest in technology being utilized throughout the machine with productivity in mind. From its EtherNet/IP architecture for easy automation and integration into systems and cells, to its Motion Control for fast and smooth operations used in all industries, the MEGA/TERA Series has quickly become one of the industries leading machine tool lines of Vertical Machining Centers.

The MEGA/TERA Series has been refined through years of research and development of new technologies that greatly enhance the machines for the rigors of the Mold and Die industry.

All series are equipped with

■ 15,000 rpm Built-In Spindle

■ Thermal Compensation (DYPEC)

■ Micro Dynamics HMI

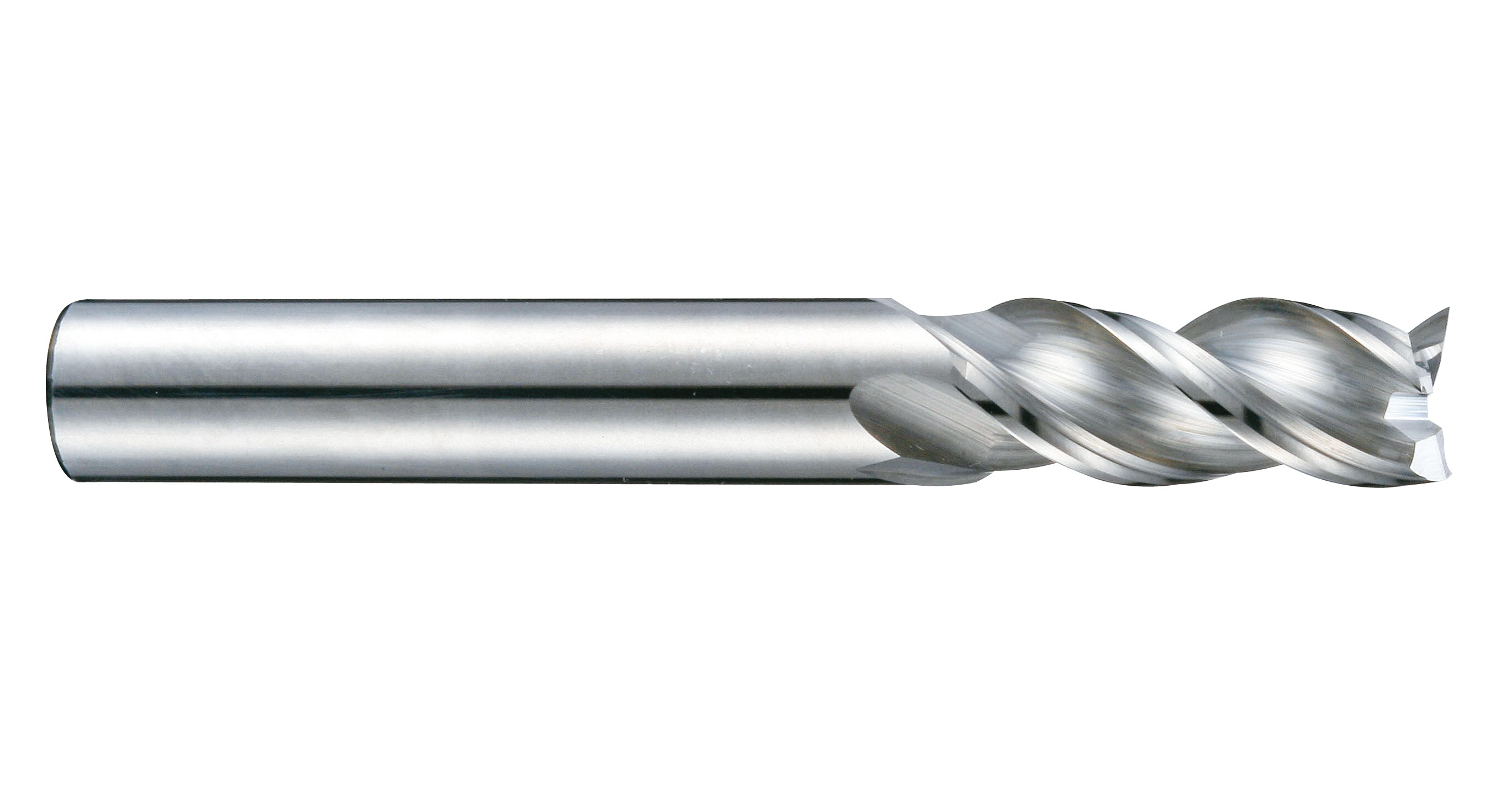

7-LEADERS CORP.

Product Description :

End Mills for Aluminium- 3 Flutes

Design with sharp cutting edge, high removal cutting geometry, and fine grinding smooth surface to prevent sticking problem.

Higher finishing of cutting edge to have better surface roughness after processing.

Application for roughing and finishing in various Aluminium.