Theme

Digital Transformation

Green Transformation

NINE-9 CUTTING TOOLS CO., LTD.

Product Description :

Nine9 chamfer mill is designed for chamfering and countersinking with an indexable insert.

The insert is a specifically designed for use in high speed machining ; the multiple flutes

provide for increased feed rate, optimizing performance and reducing cutting time.

High performance chamfer tool for upgrading your machining process.

For front and back chamfering. Eliminates 2nd operation or deburring time.

● Excellent Repeatability

• Smallest Indexable counter sink, diameter ø7 mm.

• The insert is dual-relief angle, specially edge honning and optimized coated for high cutting speed.

• Optimized the number of teeth on the holder to achieve higher feed rate.

● Economical

• Each insert has 4 cutting edges.

• Long tool life.

● Applications

• For front and back chamfering.

• 90° counter sink and 45° chamfering.

• For counter sink, circular chamfering, contour chamfering and face milling.

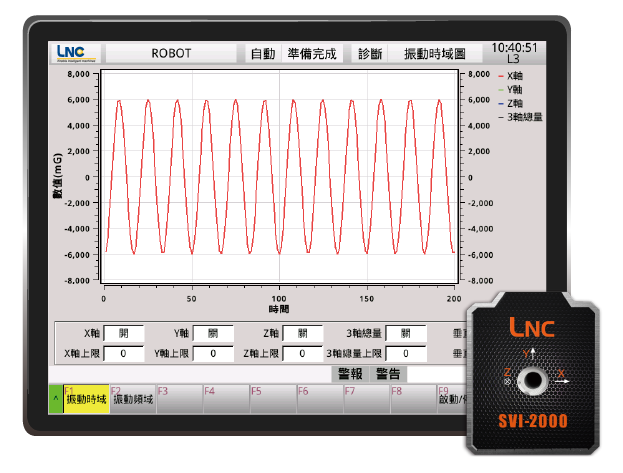

LNC TECHNOLOGY CO., LTD.

Product Description :

‧Low profile, high performance, easy installation, high applicability

‧High sensitivity, high precision

‧measurement:±16G, extremely low signal /noise ratio

‧XYZ three-axis vibration detection

‧Measuring frequency 3.32kHz(max.)

‧EtherCAT protocol

‧Water and oil proof, great anti-interference ability

‧Support time domain graph, frequency domain graph, abnormal vibration section marking of program function

‧Support smart function development: Broken tool detection, abnormal vibration detection, spindle protection, tool wear, adjustment assistance, equipment health inspection, etc.

SIEMENS LTD., TAICHUNG BRANCH OFFICE

Product Description :

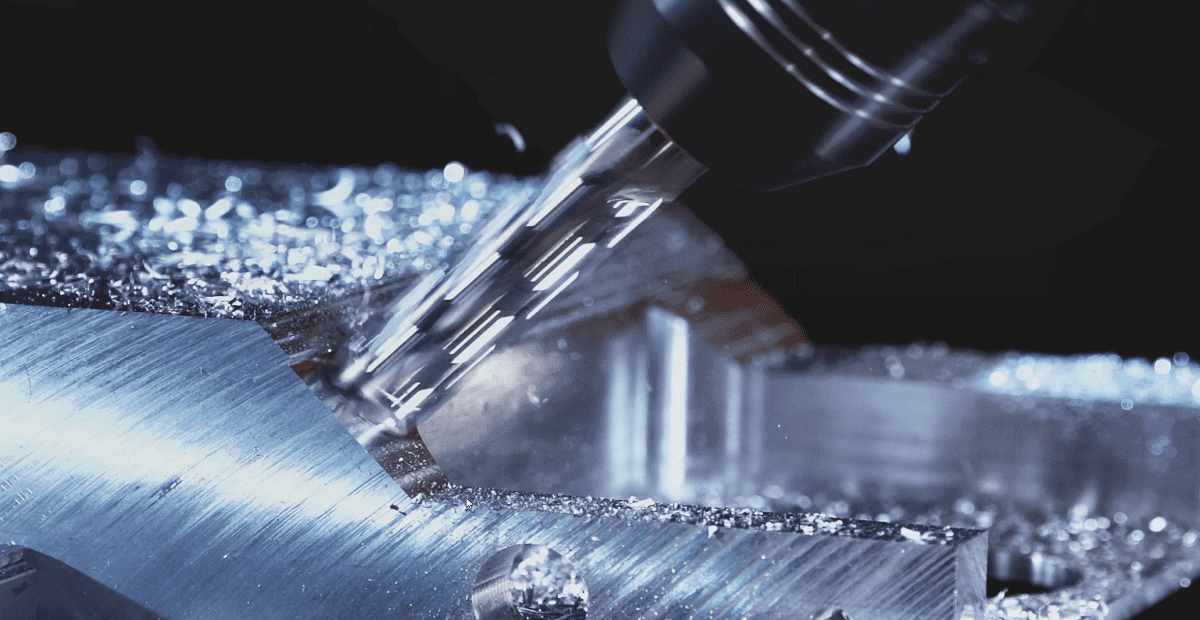

Optimizing the machining process using real-time data

Machine tool users incur unnecessary costs as a result of tool breakages, unexpected surface quality anomalies, cutting tools being replaced too early, and longer non-productive machining times. Do you know how to avoid these pitfalls and save money by leveraging your real-time cutting data?

FAIR FRIEND ENTERPRISE CO., LTD.

Product Description :

1. Improve tools life and cutting efficiency, especially ideal for particular process requirements of brittle or hard、 high-temperature superalloy and composite materials.

2. Increased precision and quality of the workpiece to achieve excellent cutting results. (smooth edge)

3. Perfected ultrasonic control technology for easy selection, automatic frequency, and power adjustment.

4. The strong chipping of chassis concentrates the chips into the path as ensures high efficiency.

5. Anti-scale cover + KEVLAR armor material, used in glasses, ceramics super hard metal processing which can preventing dust protection system effectively.。

NUMEN MACHINERY CO., LTD.

Product Description :

* Double column structure and high rigidity design can

provide mold processing industry with high precision

and high efficiency of the performance.

* The superior cutting rigidity, more user-friendly

operation mode and machine stability can improve

the efficiency of operators.

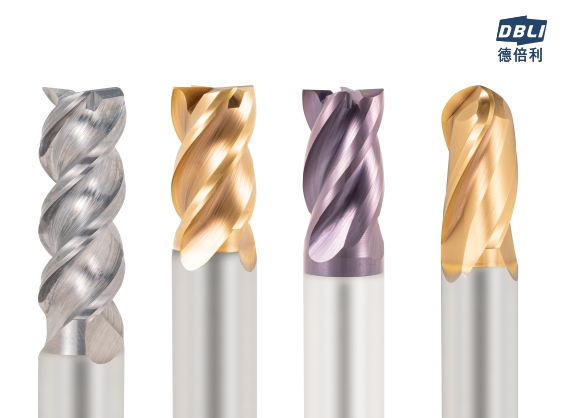

DEEP JET INDUSTRY CO., LTD.

Product Description :

1. Use in high speed machining and hard workpiece machining. It improves the quality and machining speed which is the best choice for precision processing.

◆Carbide Asymmetric Corner Radius End Mill (Steel)-Asymmetric helix angle 40º/42º and unequal flute design to effectively reduce the vibration rate and increase the tool's stability.

◆Carbide Asymmetric End Mill (Aluminum)- Reinforced asymmetric 50/50.5/51 and unequal flute design to effectively reduce the vibration rate and increase the tool's stability. This makes the surface smoother.

◆Carbide Asymmetric End Mill (Steel)-Reinforced asymmetric 36º/38 º design with special grinding technique to reach better surface roughness. Avoid vibration problem during machining and increase tool's stability.

◆Carbide Asymmetric End Mill (Aluminum)- Reinforced asymmetric 44.5º/45º/45.5º design with special grinding technique to reach better surface roughness. Avoid vibration problem during machining and increase tool's stability.

HERBERT ENTERPRISE CO., LTD.

Product Description :

1.Modelling

The main structure could do universal machining with soft or hard jaws without any limit of angle.

2.Function

The universal vise is suitable for milling, lathe, and CNC machining center especially for 5-axis CNC machining center with 200-1000cm machining table and 12000 rpm. The swivel base can move in two-way to find the center point, easy and efficient to meet customer’s requi-rement.Can be mounted to CNC machining center to rotate the work-piece via swivel base for processing.

3.Quality

With the heat treatment alloy steel, it’s hardness reach 50-60 degree with high durable quality. The parallelism accuracy reaches to 0.01mm. The main body can support the sliding base increase its stability.

4.Innovative

HERBERT TMV successfully conveys the spirit of HERBERT - reliable, stable, innovative and professional.

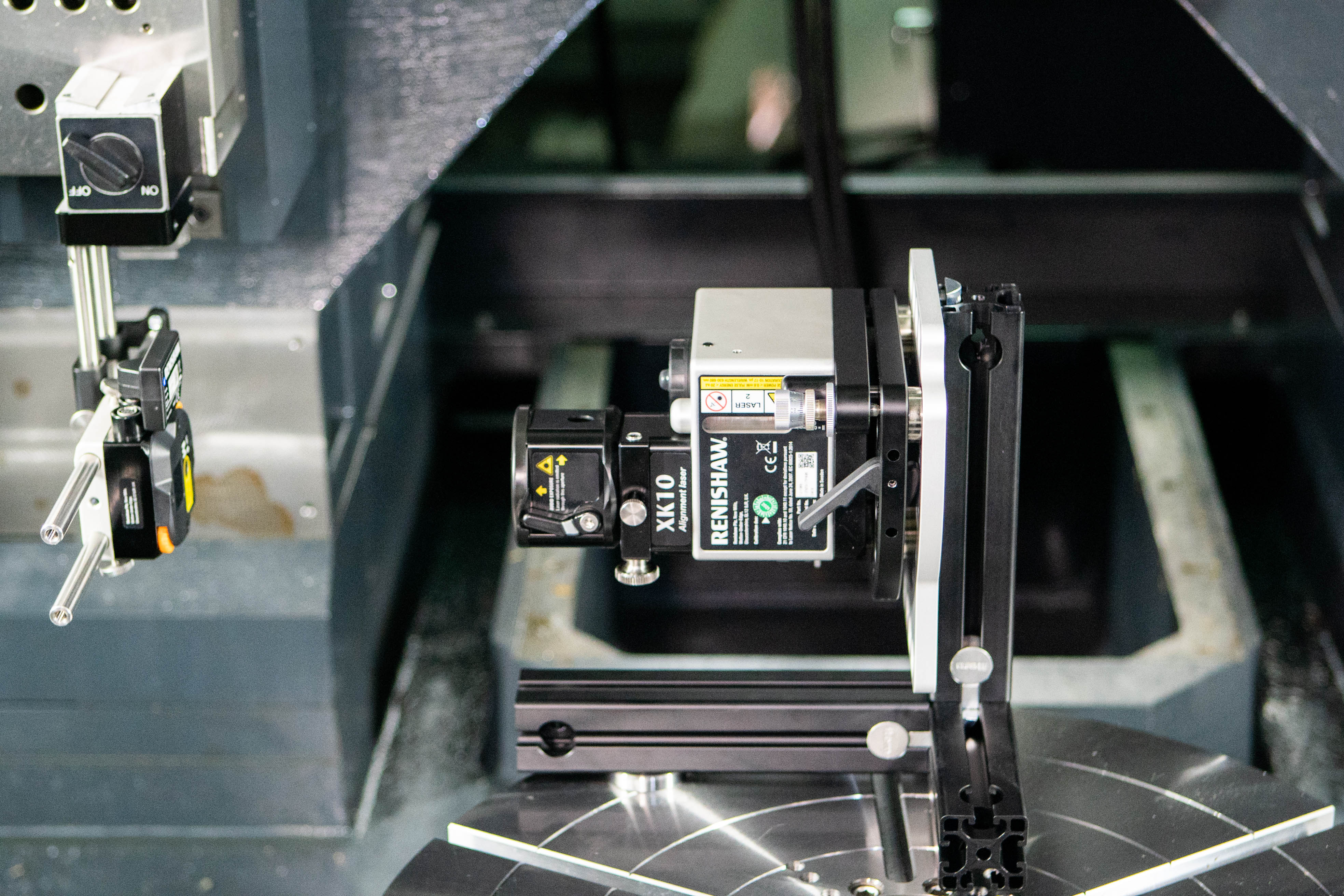

G-TECH INSTRUMENTS INC.

Product Description :

★POSITION INSPECTOR: Quick health check of your machine tool linear axis

★POSITION ANALYZER: In-depth analysis & diagnostics of your machine tool linear axis

★ROTARY AXIS INSPECTOR: Quick health check of your machine tool rotary axis

★ROTARY AXIS ANALYZER: In-depth analysis & diagnostics of your machine tool rotary axis

★SPINDLE INSPECTOR: Quick health check of your spindle accuracy & performance

★SPINDLE ANALYZER: In-depth analysis & diagnostics of your spindle accuracy & performance

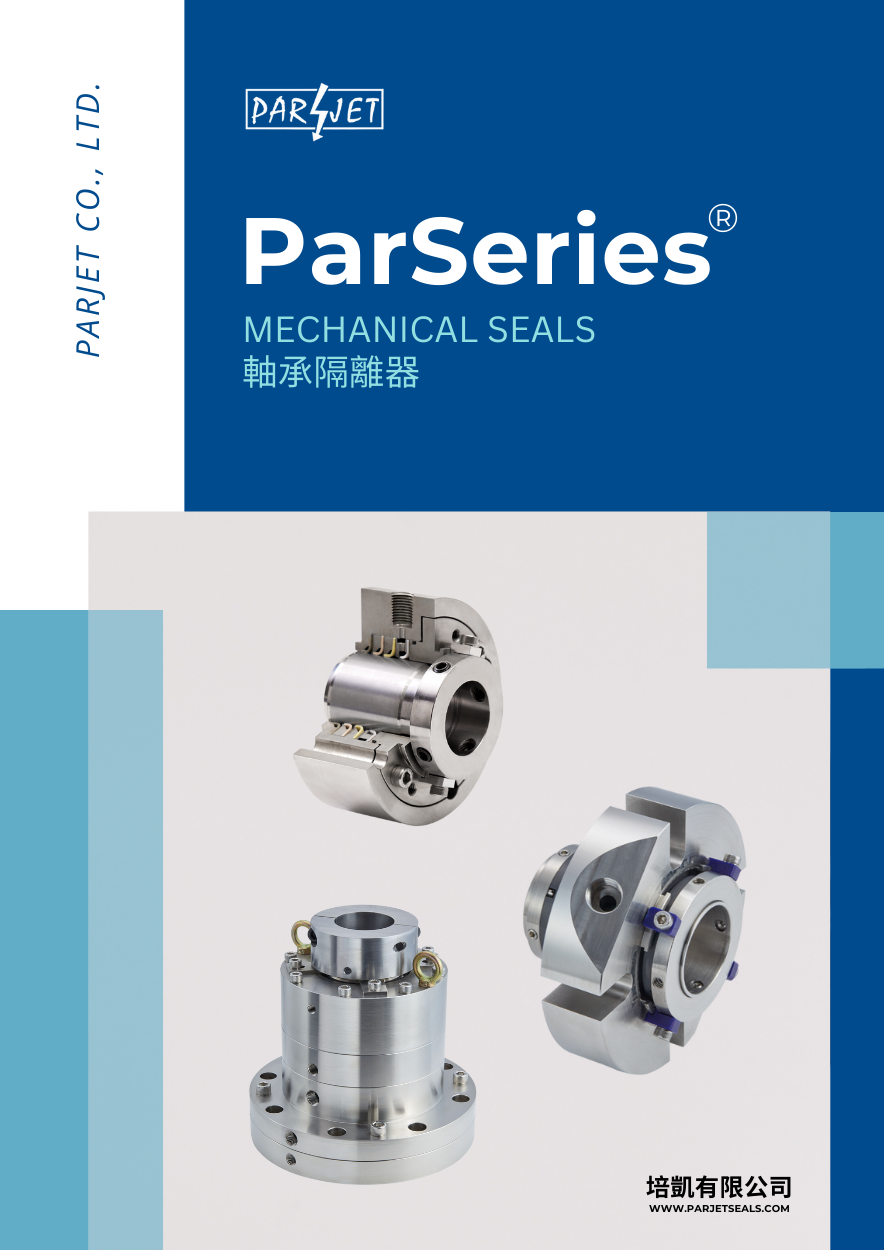

Parjet Co.,Ltd.

Product Description :

Parjet has become a leader in the sealing industry by providing a full range of sealing solutions. For every complex seal application, Parjet has a solution.

Mechanical shaft seals are often an ideal sealing method. They provide the most suitable sealing method under many conditions especially high temperatures, high pressures, high viscosity (sediment), high speeds, large diameters, and many others. Most importantly, we have a highly technical mechanical seal providing and customizing the most optimal sealing solution for you.