Theme

Digital Transformation

Green Transformation

YEU-LIAN ELECTRONICS CO., LTD.

Product Description :

The Manual Pulse Generator Engraving Handwheel by YEU-LIAN is designed for CNC operation panels, enhancing applicability through metalworking materials. It protects against dust, water, and oil, with an optical rotation, non-contact detection structure ensuring no vibration affects signal output. The encoder withstands 3 million cycles maintaining high precision, and features anti-static design, wide voltage range (DC5V to 24V), high reliability, and strong consistency. It's easy to install, suitable for various automation equipment, and CNC systems, ideal for CNC MPG pendant controllers and CNC operation panels.

ROYAL PRECISION TOOLS CORPORATION

Product Description :

▶High speed

▶High precision, high efficiency

▶High dynamic rotary accuracy

▶Balancing adjustment within G1, low vibration

▶Modularized easily

▶Thermal displacement, high stability

▶Short overall length, low inertia

▶High motor power, high moments of inertia

▶Applications: Milling, turning, mill-turn, multi-spindle

BLUM PRODUCTION METROLOGY CO., LTD.

Product Description :

– THOUSANDS OF MEASURING VALUES OF ALL TOOL CUTTING EDGES PER SECOND

– UP TO 60% LESS MEASURING AND CHECKING TIME

– MEASUREMENT AND MONITORING OF ALL KINDS OF TOOLS, TOOL FORMS AND CUTTING MATERIALS

– COMPENSATION OF SPINDLE DRIFT AND TOOL CUTTING EDGE RUN-OUT ERRORS

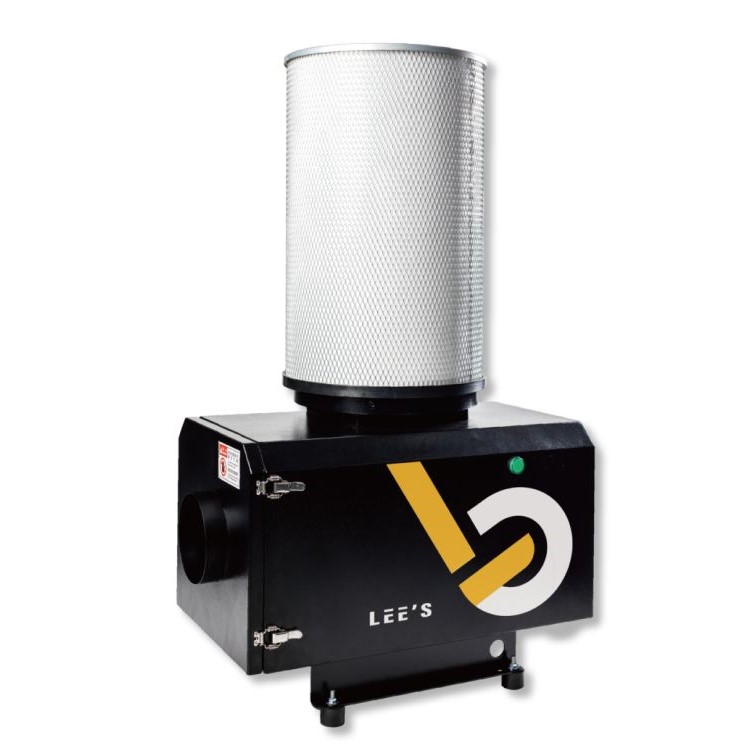

TOP POWER MACHINERY ENTERPRISE CO.

Product Description :

We exclusive patented technology and is committed to developing and producing products that meet global environmental protection goals. The machine is made of all metal and stainless steel materials. From the perspective of environmentally friendly equipment, it realizes the concept of net-zero and low consumables. Using the principle of physical centrifugation, a unique oil throwing device is designed, which can effectively extend the maintenance cycle and increase the filtration rate of oil smoke generated by the processing machine to more than 85%. In addition, the new generation design improves the performance of the machine with the same horsepower by 50%. Under the same efficiency, the power saving rate can be as high as 200% to 400%.

TONGTAI MACHINE & TOOL CO., LTD.

Product Description :

‧The VP-12 combines the advantage of a smaller footprint with a large internal machining space, equipped with a high-speed spindle to meet the requirements of efficient and precise machining.

‧Direct-drive spindle BBT-40 provides a high rigidity and high efficiency.

‧The tool magazine allows for flexible tool placement and pre-selection, coupled with a high-speed ATC mechanism to reduce non-cutting time, showcasing efficiency similar to drilling and tapping machining centers.

‧High quality spindle and high rigidity structure design subject to high standards of machine accuracy to achieve good cutting performance.

‧By Tongtai production system, we check every detail process from design, manufacturing, assembly and QC.

GRINTIMATE PRECISION INDUSTRY CO., LTD.

Product Description :

a.Equipped with exclusive high rigidity hydrostatic rotary table, static rigidity greater than 400kgf/μm, Φ600/800table with a load capacity of >10000KG.

b.Mitsubishi/Fanuc controller available, with human-machine interface(HMI) which features fast communication and convenient for user-friendly operation.

c.The high rigidity of our hydrostatic spindle both radially and axially enables our spindles to produce a wide range of finishes-from speedy heavy cutting of >0.3mm to mirror-like finish.

d.To maximize stability and load capacity, the Y-axis(up/down) and the Z-axis (forward/backward) of the grinding wheel spindle are equipped with SCHNEEBERGER/THK/NSK lineal guideway.

e.Equipped with THK/NSK high precision ballscrews, ensuring the zero backlash feeding.

f.Our products are on hundred percent designed and manufactured in Taiwan. To guarantee the stability of machine, all of the cast components go through a pressure relieve process

KO-YAN PRECISE MACHINERY CO.,LTD

Product Description :

GJ-400 series from COMIRK combines internal grinding and cylindrical grinding in a single machine. Multiple face grinding can be accomplished with one setup for the work-piece. This machine not only saves considerable amount on machine investment costs and labor costs, but it also features dramatically upgrade for better machining efficiency and machining accuracy.

Machine Features

-Various speed of spindles selection allows for the highest grinding efficiency

-Double wheel spindles exhibit high efficiency internal and external grinding

-Internal, external, end face and tapered face can all be ground in one process

-Highly rigid machine structure ensures the best possible stability during grinding

-X, Y, Z axes are all mounted with high precision linear guide-ways.

-This machine is equipped with a FANUC CNC controller

-Multi-face grinding requires only one setup for the work-piece.

-Non-circular grinding function is available (Optional)

-Fully enclosed splash-guard

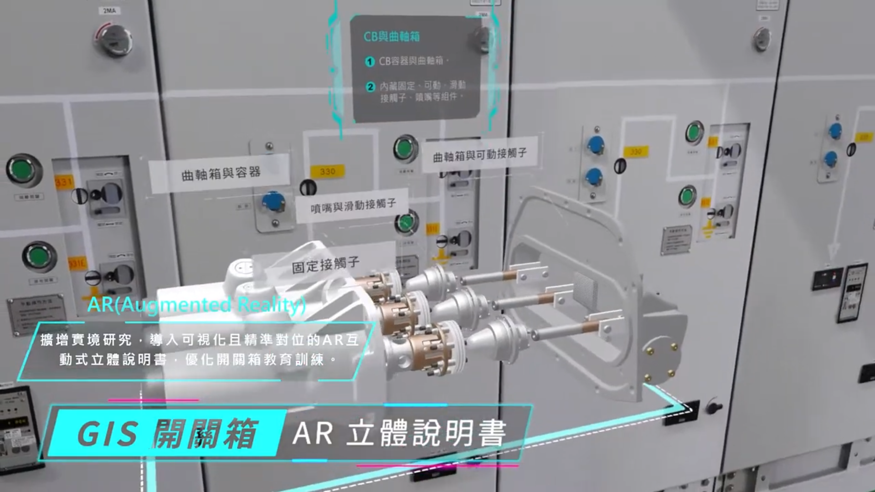

Administration for Digital Industries, moda

Product Description :

The Industrial XR SOP Solution""utilizes AR/VR/MR cross-platform integration technology to ensure seamless operation across various devices such as smartphones and head-mounted displays. It is specifically designed for the industrial sector as an XR intelligent carbon reduction integration platform service.

It's key features include support for ""cross-temporal"" information transmission and real-time monitoring, enabling precise and instant ""cross-span"" collaboration capabilities. Through the integration of virtual and augmented reality, information is transformed into a ""visualized"" presentation, allowing users to intuitively understand and operate, thereby assisting enterprises in effective resource management, reducing waste, and helping industrial production lines lower carbon footprints. This, in turn, improves energy efficiency and achieves a more environmentally friendly production model.

The application scope covers various stages of industrial production, including machine equipment, factory premises, vocational training, remote collaboration, maintenance and operation, and business showcases. Through comprehensive cross-platform integration technology, it provides intelligent, efficient, and eco-friendly solutions.