Theme

Digital Transformation

Green Transformation

HO CHEN MACHINERY & ELECTRIC IND. CO., LTD.

Product Description :

XYZ軸行程:1000x600x500 mm (39"x24"x20") inch

工作台:1250x750 mm (49"x29" )inch

最大工件:2000x1150x625 mm (79"x43"25") inch

最大工件重:4500 kg

最大電極重:350 kg

機器淨重:5700 kg

油位高度: 110-450 mm (4"-18" )inch

佔地面積尺寸(長x寬x高):4010x4050x2880 (158"x159"x113") inch

電極板至工作台面距離:430-930 mm (17"-37")

過濾箱:2

過濾網:4

容量:1900公升

3D CNC WINDOWS CE 控制器特點:

> 本系統是採用Windows CE 控制器。

> 採以對話式視窗來呈現且搭配圖片描述功能。

> 具有專門維修畫面來加快維修速度。

> 本機三軸均採用數字尺回授之全閉環迴路設計,故能使定位精度及ORBIT-CUT加工精度及效率大幅提升。

> 具有良好且簡易的操作介面。

*常用的功能鍵都在操作面板上直接使用。

*具有快速按鍵功能。

> 可加裝ATC自動換刀及加裝C軸360度分度,可自動修飾從粗加工至超細加工一次完成。

> 對話式程式,提供各種擴孔模式(各種快速尋邊,尋中心、尋基準點功能)。

> 具有較高顏色的畫質(與PC相同高畫色)。

> 可做自動多段加工(粗→中粗→中細→細→極細),最多可達10段。

> 加工條件採用加工檔案方式儲存,具有無限組加工條件,每組加工條件可直接編輯修改或儲存,編輯簡易查詢方便。

> 自動尋原點功能及多點座標記憶功能。

> 1/2設計功能及ARC自動放電波形偵測與自動調整。

> 自動中心測位自動補償,可尋孔中心尋孔最深點。定孔加工(循環式、獨立式),適合不同加工情況。放射狀、圖形、方形、直線(向量式)、錐度、45°擴孔加工。

> 三軸直線、二軸圓弧、三軸螺旋。

> 中/英文版及公/英制切換和Z軸快上、快下及慢上、慢下功能。

> 單軸側放,三軸,六種方向(平面旋轉)。

> 所有警報都可詳細描述發生的問題點、紀錄時間、日期。

> 採光學尺Close-loop位置控制,精度高。

> 自動編輯。可依材質、面積、加工深度、單側間隙、最終電流、電極磨耗等設定。

> CNC機型同樣具有傳統式等能量釋放功能,加工穩定快速,電極消耗小,表面精度均勻。

> 監視畫面加工路徑顯示和圖形顯示功能。

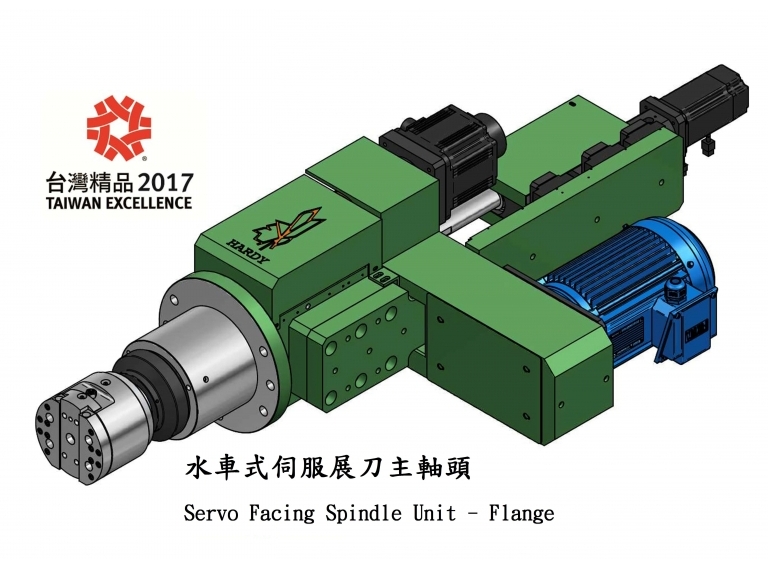

CHIEN CHENS MACHINERY CO., LTD.

Product Description :

Specification

Table size: 1515 x 470 mm

Longitudinal travel: 1300 mm

Cross travel: 600 mm

Y slide way width: 720 mm

Z Slide high: MAX 810 mm

Z Slide way width: 420 mm

Spindle taper: NT#40(BT)

Spindle motor: 5HP / 4P

Spindle speed: 70~3600 RPM

Feeding speed: 10~6000 mm/min

Ballscrew: Ø32 mm C5

Net weight: 3500 kgs

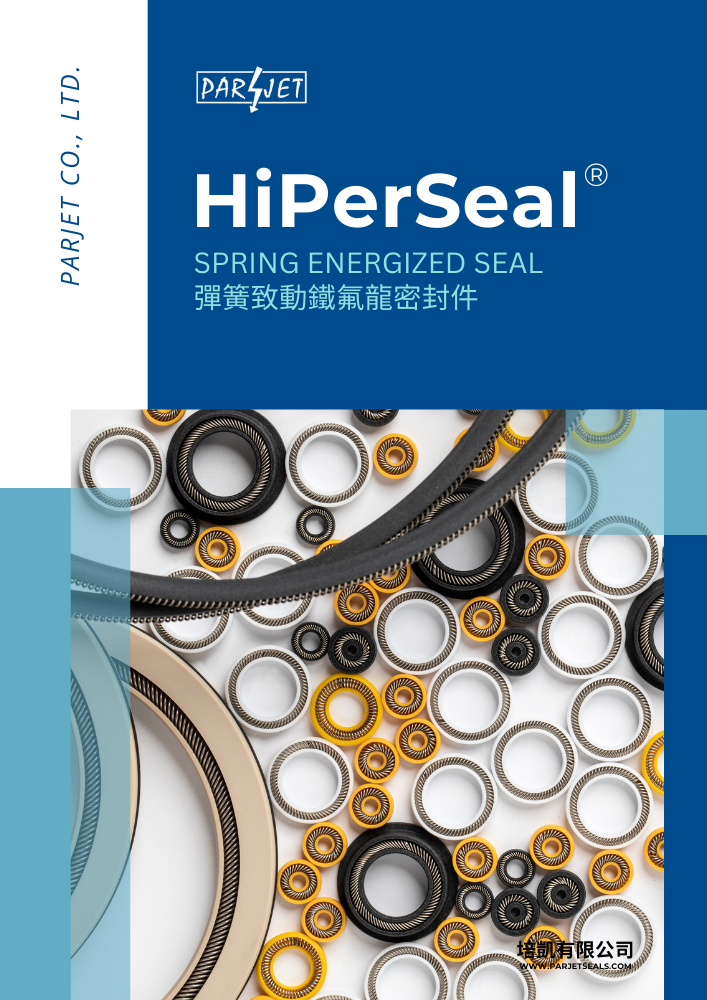

Parjet Co.,Ltd.

Product Description :

HiPerSeal®, aka Spring Energized Seal and Teflon Spring Seal, is a U-shaped machined performance polymer that utilizes a single spring energizer to provide force for the sealing lips. The seal jacket is made from PTFE compounds using high-performance polymer fillers to enhance overall spring seal life and wear resistance properties. The system pressure ultimately increases the sealing force and creates a leak tight seal. Because the spring loaded seal utilizes a spring, slight misalignment is tolerated, and the sealing force and jacket wear is more consistent. Spring energizers are available in corrosion resistant metal alloys such as stainless steel, Elgiloy and Hastelloy to meet the most serious corrosive and high temperature applications. We offer a wide variety of springs energizers including Canted Coil springs, Helical springs and Cantilever springs. For more information, you may refer to the tab "Spring" under "Products".

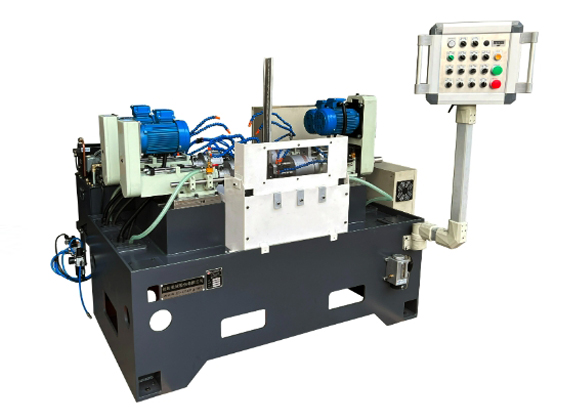

YI CHANG MACHINERY CO., LTD.

Product Description :

Linking a made horizontal Unith drilling machine and tapping machine with a hydraulic sliding table, assemble with an automatic loading and unloading system, enables rapid completion of drilling, tapping, and double-sided chamfering tasks.

This setup saves labor and allows precise control of relative positions.

If you have any thoughts or inquiries about our machine, please leave a comment below or call our company. We look forward to engaging and communicating with you!

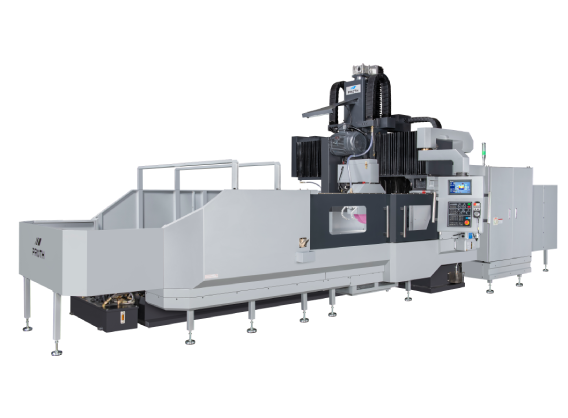

GRINTIMATE PRECISION INDUSTRY CO., LTD.

Product Description :

a.Equipped with exclusive high rigidity hydrostatic rotary table, static rigidity greater than 400kgf/μm, Φ600/800table with a load capacity of >10000KG.

b.Mitsubishi/Fanuc controller available, with human-machine interface(HMI) which features fast communication and convenient for user-friendly operation.

c.The high rigidity of our hydrostatic spindle both radially and axially enables our spindles to produce a wide range of finishes-from speedy heavy cutting of >0.3mm to mirror-like finish.

d.To maximize stability and load capacity, the Y-axis(up/down) and the Z-axis (forward/backward) of the grinding wheel spindle are equipped with SCHNEEBERGER/THK/NSK lineal guideway.

e.Equipped with THK/NSK high precision ballscrews, ensuring the zero backlash feeding.

f.Our products are on hundred percent designed and manufactured in Taiwan. To guarantee the stability of machine, all of the cast components go through a pressure relieve process

PROTH INDUSTRIAL CO., LTD.

Product Description :

1.A : Auto-cross H : Hydraulic longitudinal R : Rapid up/down.

2.Hydraulic System : Two single-acting hydraulic cylinders are used with their piston rods anchored at very specific positions.This enhances rigidity and creates a very stable table motion; table float is eliminated.

3. Grinding spindle : The precision high rigidity spindle is of a cartridge type design. This provides for easier accessibility and service when maintain is needed.

4. Upgradable CNC numerical control.

R PLUS TECHNOLOGY CO., LTD

Product Description :

1. Automatic detection cutting processing work. Prevent cutting process failure or missing.

2.After cutting the part surface smooth with better quality.Good quailty.High stability.

3.Best cutting state feedbacck signal function. Can be connected to the manipulator or robots. The installation is more convenient.Widely versatility.

4.Automatic testing possesses function. While system upfrades to industrial 4.0, ours products still can be used. Reducing the risk of investment and waste

BUFFALO MACHINERY CO., LTD.

Product Description :

AXILE’s automated G6 Robotic Pallet Changer (RPC) solution features a 2-axis robot that keeps machines supplied with workpieces 24/7 from the back side of the machine. Part processing continues simultaneously within the machining center while operators deal with workpieces at the holding area at the back, significantly raising production efficiency to boost throughput.

The G6 RPC solution caters to diverse production requirements, with multiple options available based on workpiece specifications:

8 pallets (workpiece max. size 500 x 305 mm; max. weight 220 kg)

10 pallets (workpiece max. size 400 x 305 mm; max. weight 220 kg)

16 pallets (workpiece max. size 230 X 305 mm; max. weight 98 kg)

20 pallets (workpiece max. size 160 x 250 mm; max. weight 30 kg)

With AXILE’s digitalized intelligent automation solutions, manufacturers can eliminate production bottlenecks and ramp up production.