Theme

Digital Transformation

Green Transformation

WEXTEN PRECISE INDUSTRIES CO., LTD.

Product Description :

■All models use DC inverter compressors with smooth start-up, no instantaneous large

starting current characteristics, and low power consumption.

■When the heat load is low, the cooling unit operates at a low load, with high energy efficiency.

■The exclusive design of the multi-function LCD panel with an accuracy of ±1℃ can keep the

electric cabinet at a constant temperature, control heat sources, and improve the lifespan of

electronic components.

■ Uses environmentally friendly refrigerants with low Global Warming Potential (GWP) values.

■More than 95% of materials that can be recycled, contributing to environmental protection.

WIN HO TECHNOLOGY INDUSTRIAL CO., LTD.

Product Description :

主軸箱 <br />

全部齒輪及槽軸都用合金鋼製成<br />

經滲碳處理及精密研磨。 <br />

旋轉式變速機構操作簡單。<br />

<br />

齒輪箱 <br />

全能車製螺紋機構,任意車製。 <br />

公制螺紋、英制螺紋、模數螺紋、<br />

徑節螺紋,不需變換齒輪。<br />

<br />

床身 <br />

高剛性之肋骨結構。 <br />

3V床軌設計,精度永保如新。 <br />

高精度寬大床面、經淬火並研磨。 <br />

一體成型落地底座適合重型工件並延長使用年限。<br />

<br />

兩頂心距離 <br />

全系列兩頂心多300mm可實際車<br />

削更長工件。<br />

<br />

尾座 <br />

軸承支撐,移動輕便。<br />

<br />

護床 <br />

滑座與床鞍加長加寬,重切削更強。 <br />

調整容易的超負荷安全裝置。<br />

SPINDLE 配有潤滑油手動和自動雙重潤滑給油系統。 <br />

<br />

主軸 <br />

超大直徑主軸,主軸孔徑153mm,230mm(OPT)。 <br />

超精密軸承三點支持式。<br />

<br />

快送及自動跳脫 <br />

自動縱向可任意控制跳脫距離,有縱向及橫向<br />

快送選擇。<br />

WEXTEN PRECISE INDUSTRIES CO., LTD.

Product Description :

■Single refrigerant circuit is with multiple oil circuits, and it provides independent flow rate and pressure precisely.

■ Different liquids can be controlled temperature at the same time,and it can be customized.

■ Temperature control of Dual-PCB for each of plural circuits and it can adjust temperature individually.

■ It has temperature compensation and preheated function.

■ Temperature control precision is +0.5~1.5 ㆍC. (It can be customized of other temperature control precision.)

■ Saving about 50% of floor space.

■ Using high-efficiency environmental refrigerant and without pollution.

■ Up-to 95% materials of machine are recyclable and eco-friendly.

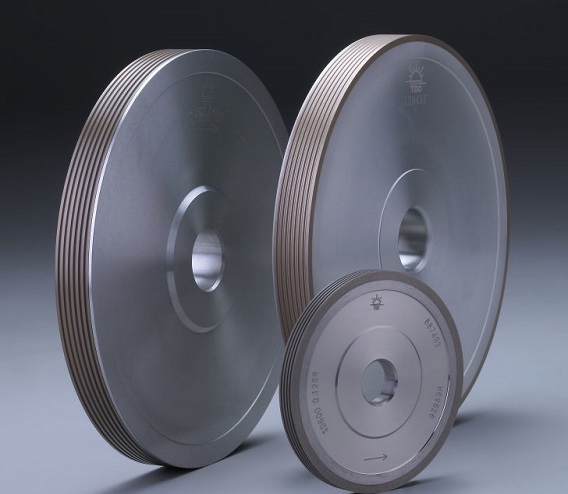

TAIWAN ASAHI DIAMOND INDUSTRIAL CO., LTD.

Product Description :

* Processing Method|Grinding

* Applications|Semiconductor Material Processing

* Silicon wafer edge grinding wheels require strict shape precision and wear resistance, and require stable grinding capabilities, so metal bond grinding wheels can be used. We can provide single groove or multi groove, integrated coarse and fine grinding wheel according to customer’s requirements.

* Processing Material | Silicon Crystal

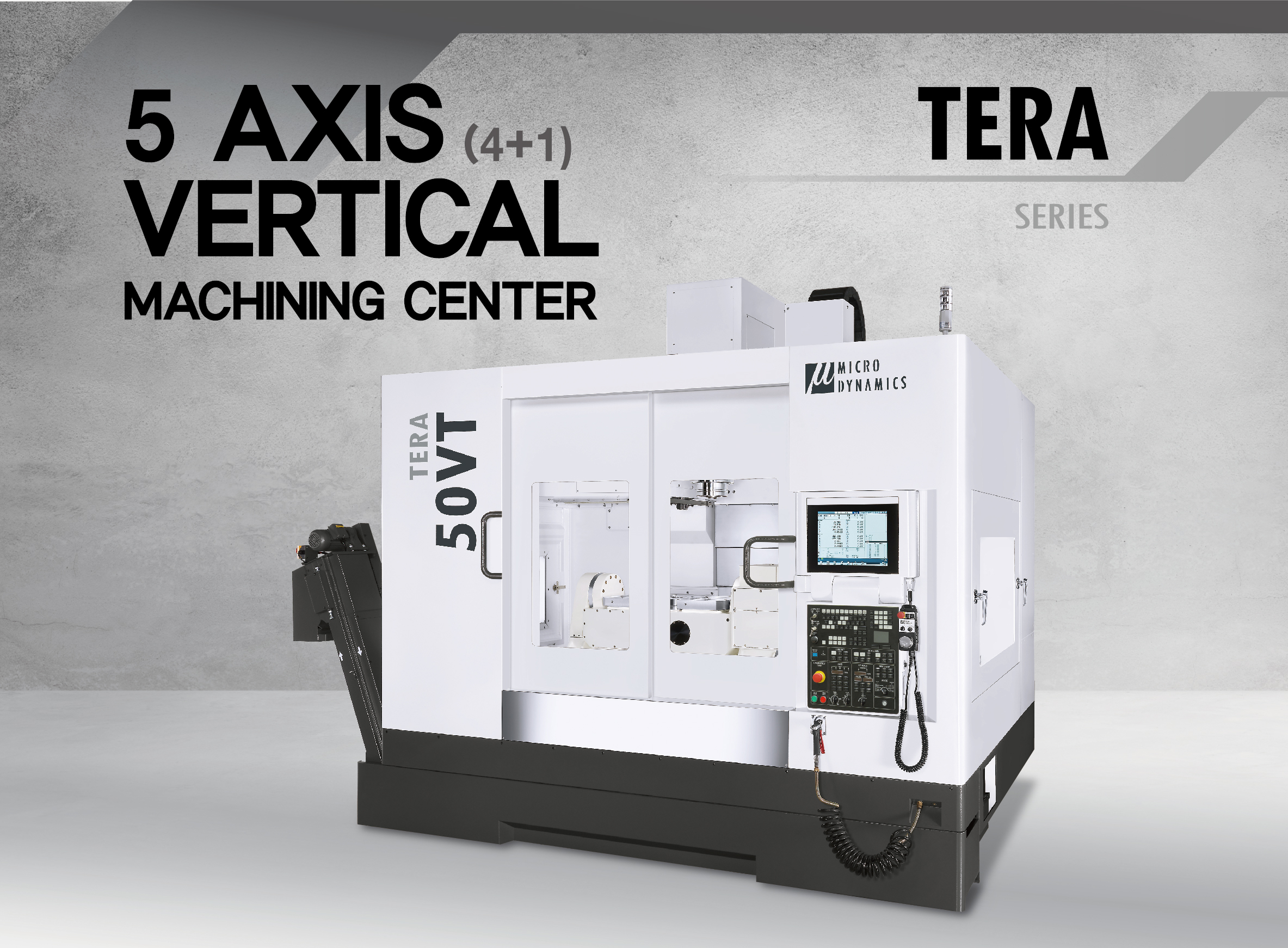

INNOSERV FA INC. TAIWAN BRANCH (BVI)

Product Description :

Micro Dynamics Vertical Machining Center Line opens a new era in multi-purpose and versatile machining centers. Compact, durable, powerful, strong and accurate, the MEGA/TERA Series starts a revolution in the market: the smallest C-frame machines provide powerful and precise results for manufacturers of dies and molds, aerospace, automotive, semi-conductor, job shops and general machine sectors.

The MEGA/TERA Series has been designed with the latest in technology being utilized throughout the machine with productivity in mind. From its EtherNet/IP architecture for easy automation and integration into systems and cells, to its Motion Control for fast and smooth operations used in all industries, the MEGA/TERA Series has quickly become one of the industries leading machine tool lines of Vertical Machining Centers.

The MEGA/TERA Series has been refined through years of research and development of new technologies that greatly enhance the machines for the rigors of the Mold and Die industry.

All series are equipped with

■ 15,000 rpm Built-In Spindle

■ Thermal Compensation (DYPEC)

■ Micro Dynamics HMI

E-TECH MACHINERY INC.

Product Description :

EGM series is a combinations of grinding operations for internal, external, end-face, groove, radius, internal and external step, and taper grinding can be executed in one chucking. Thus, it greatly increases grinding efficiency and also ensures better concentricity and accuracy of the ground parts.