Theme

Digital Transformation

Green Transformation

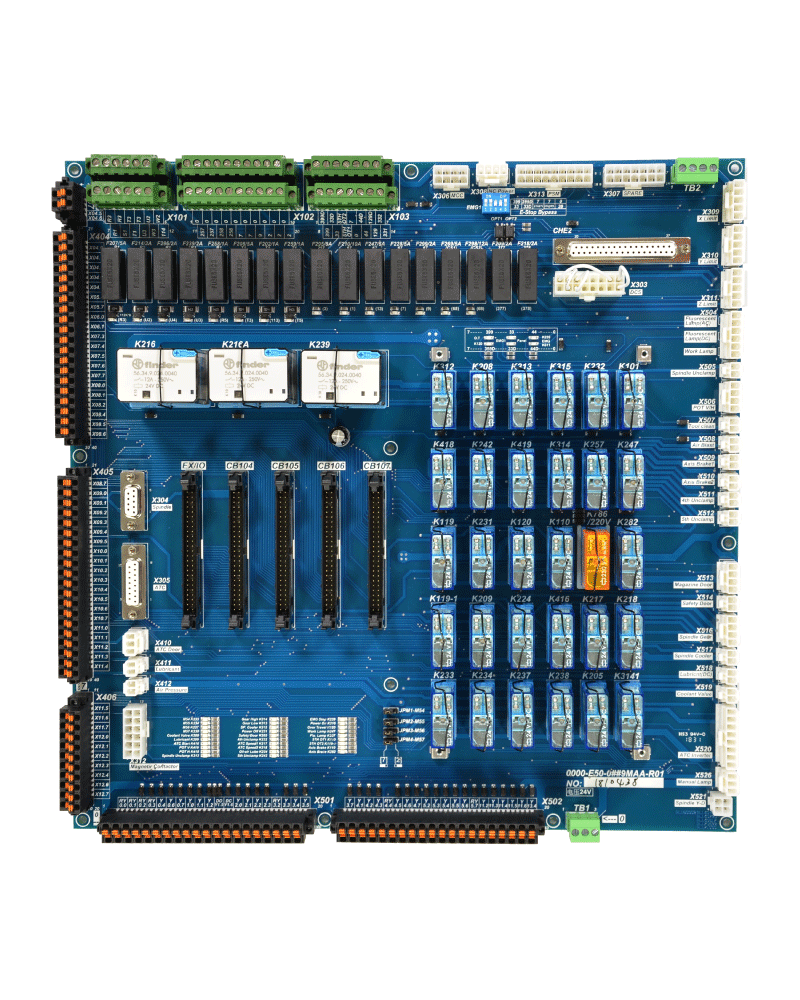

YEU-LIAN ELECTRONICS CO., LTD.

Product Description :

OEM/ODM circuit board combined adapter board, relay board, patch board and I/O board into one piece - all optimized to customers' needs. The PCB circuit board can customize various controllers such as FANUC, MITSUBISHI, SIEMENS, FAGOR, HEIDENHAIN and industrial types. Apply to CNC machines like lathes, milling machines, turning, multitasking machines, machine tools or industrial machinery.

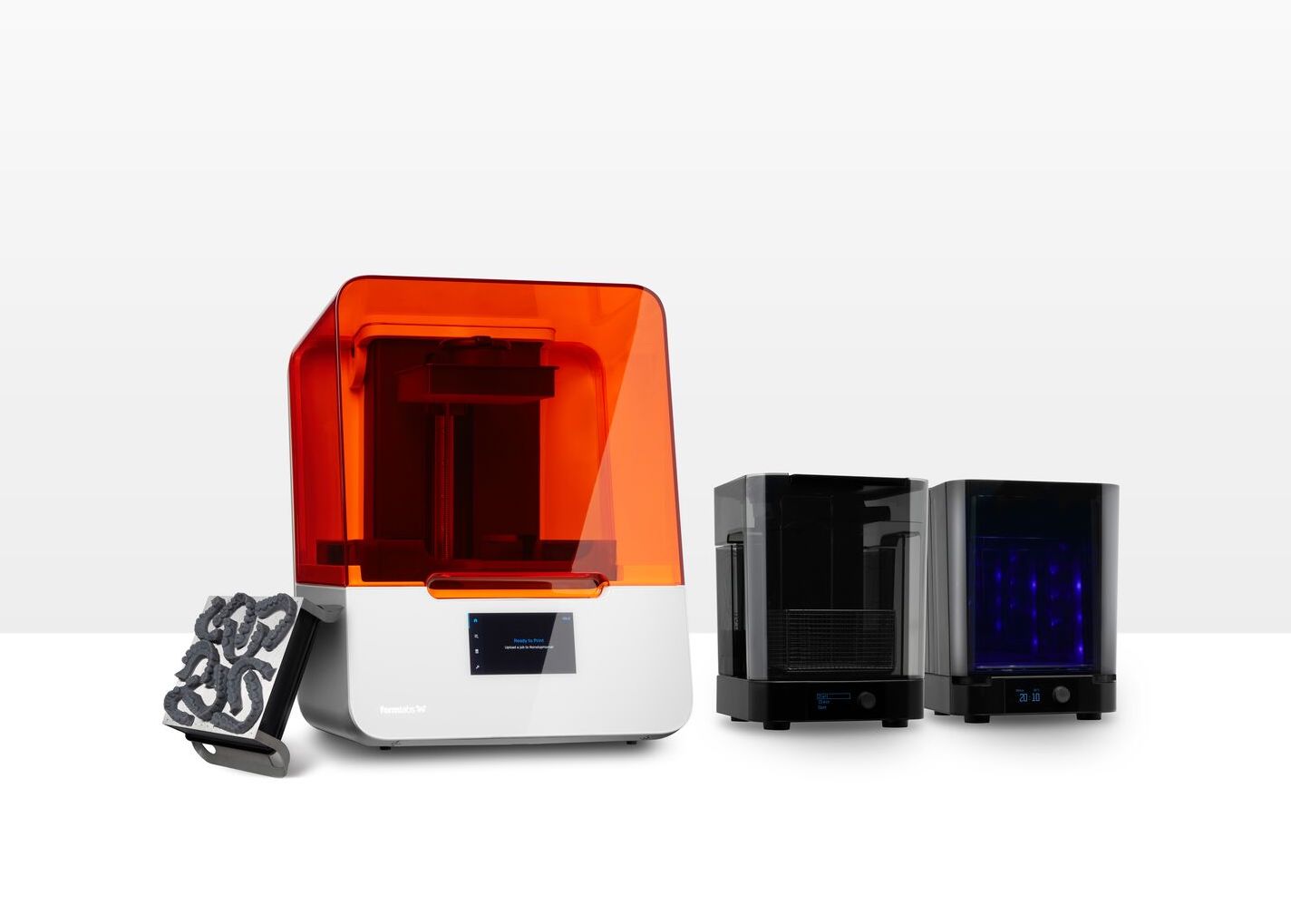

Taiwan TeamA Tech. Co., Ltd.

Product Description :

formlabs 熱銷光固化機種 Form 3+/3B+ 搭載專利研發「低應力光固化成型技術(LFS)」,其特色包含彈性樹脂槽與封閉式光學模組(LPU)等,雷射光可垂直照射到物件,大幅增加機器的可靠與穩定性,可印出高精確度、平滑度及透度更佳的高品質物件,桌面級的機種,也能達到工業級的效果。

搭配上為 Form 3+/3B+ 量身打造的後處理設備-自動清洗機 Form Wash 及恆溫光固機 Form Cure,提供完整、快速的 3D 列印製造流程。

Form 3+ 六大特色包括:

1. 前所未有的表面精細度

2. 極平滑的物件表面與透度

3. 彈性樹脂槽使成功率大增

4. 遠端列印超easy

5. 無與倫比的30多種多元樹脂材料

6. 輕觸支撐材帶來最佳效率

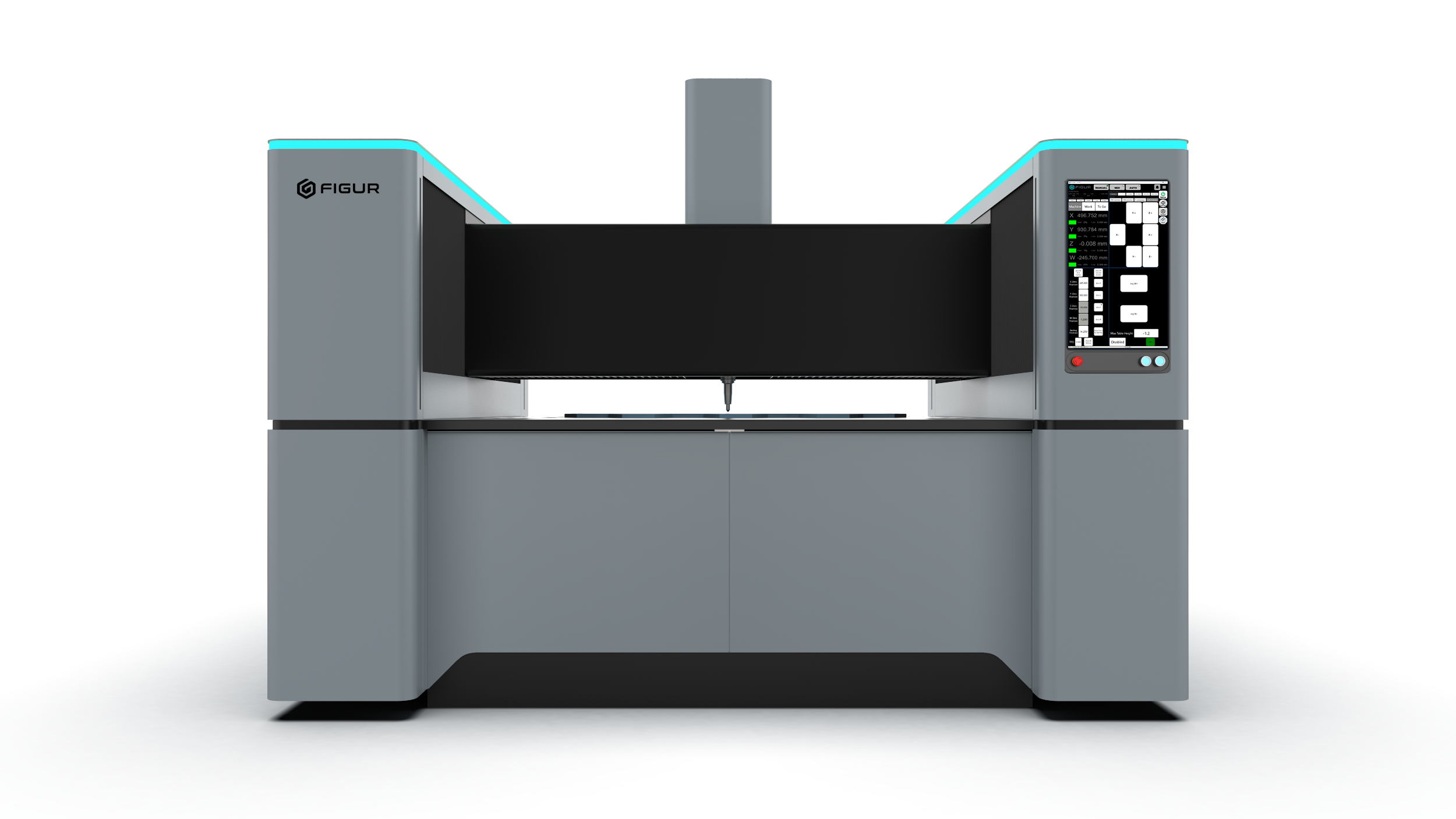

KAO FONG MACHINERY CO., LTD.

Product Description :

Optimized C-type structure of the proportion of gold design, machine rigidity and stability of good. Three-axis use the ball-type linear guideway. Achieving a perfect balance in the perspectives of promotion of precision and high rigidiy, the product is designed for the industry with high efficiency processing need. On the aspect of cutting chip with high efficiency, the performance is near perfect , the ultimate tool to enhance production efficiency and profit cration for investors. Mainly used in general precision machinery and 3C electronic parts, and automobile and locomotive industries, processing mold industry, aerospace, medical equipment industryand so on.

BENIGN ENTERPRISE CO., LTD.

Product Description :

• Heavy duty mill for wide range of applications

• Machine body is made of Meehanite casting.

• 5 HP inverter driven spindle, variable speeds

• X & Y axes automatic feeds driven by 1⁄2HP 12P motor and inverter

• Z axis rapid up-down driven by 1⁄2HP 6P motor.

• ISO 40 spindle, quill diameter 105mm

• Y & Z axes square ways

• Turcite-B coated on X & Y saddle.

• Hardened table and all slide ways.

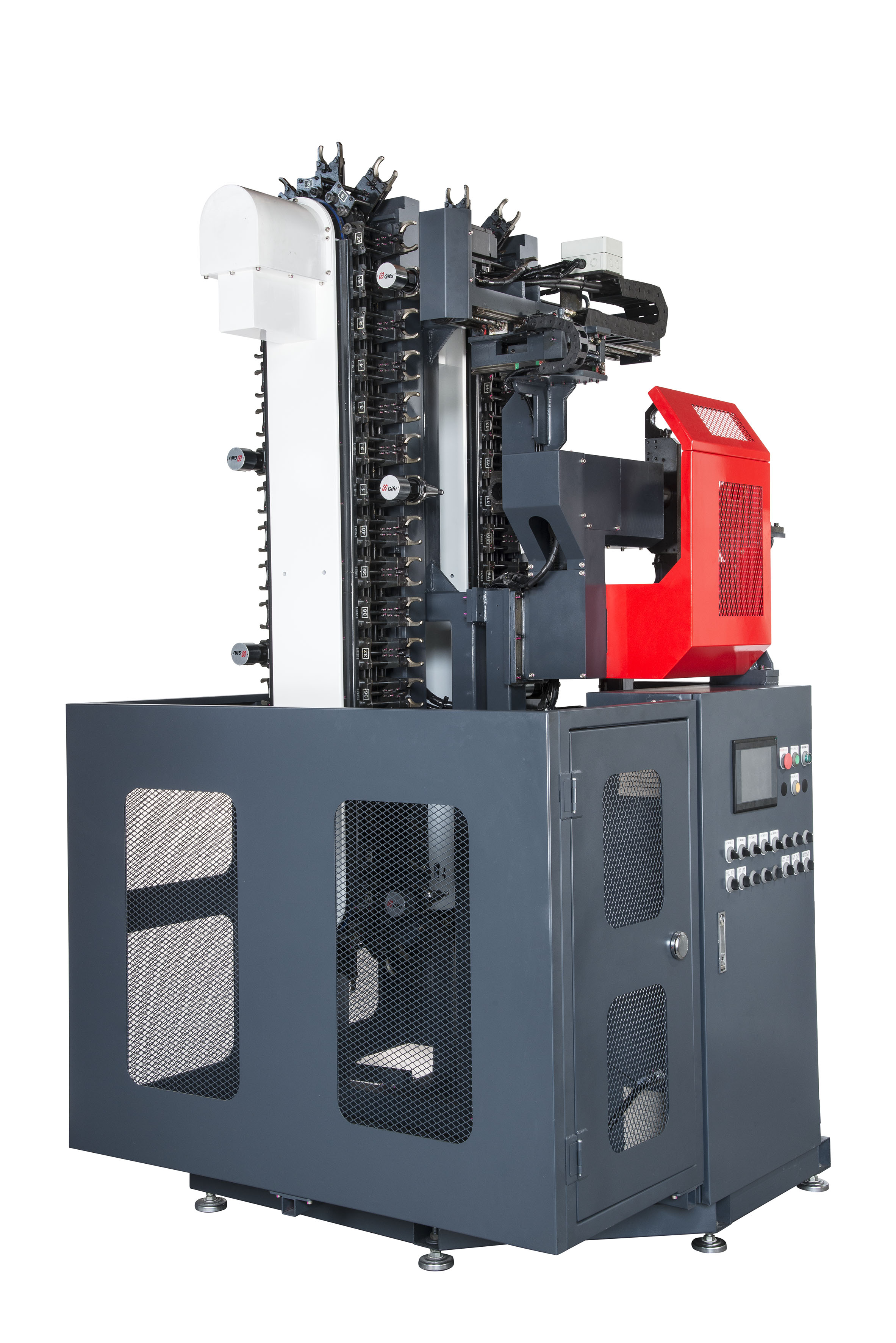

GIFU ENTERPRISE CO., LTD.

Product Description :

Applicable Specification:

BT40/CAT40/DIN40/HSK63/CAPTO6

Applicable Model:

Multi-Tasking Machines

1.The magazine can load 60/120/180 tools by front and rear allocation. Also, the magazine is adopted with high-quality and high positioning accuracy reducer and servo motor driven system.

2.The gripper replaces the tool pot to catch tools and achieve the purpose of lightweight and modularization

3.Innovative sub-tool pot tool catching system reduces 30% of the volume. The design of lightweight structure with fast moving speed achieves max. speed at 15m/min and the positioning accuracy of heavy loading is within ±0.1mm.

4.Two-stage advanced speedy tool changing system The best tool changing time can be adjusted according to different tool weights. The tool under 3 kg can complete tool changing procedure within 1 second.

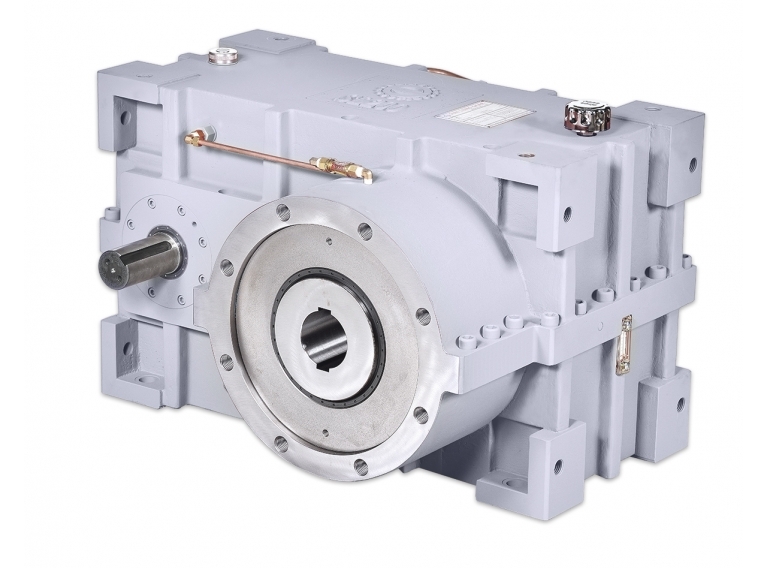

SUN LUNG GEAR WORKS CO., LTD.

Product Description :

【SL5 ~ SL250系列】 三隆研發團隊依AGMA (美國齒輪製造協會) 標準規範設計,經電腦模擬運算及應力分析安全強度之計算,創造出最佳傳遞效率、低噪音、高扭力之優質齒輪箱組合架構。搭配內部高精度齒輪結構及維修方便性設計出最實用、最美觀之獨特外型。齒輪箱上下左右的出力方向均可依客戶需求,提供最完整的解決方案。內部元件採用最高品質SKF或FAG軸承及最有效的二層防漏油NOK油封裝置與超耐磨鍍硬鉻強化處理,均為最優質確保品質的設計。本公司齒輪箱均經嚴格品管檢驗測試,對於噪音、工作溫度、振動完全符合綠能環保標準。

WELE MECHATRONIC CO., LTD.

Product Description :

1.立車主軸轉盤以進口交叉滾子軸承設計,確保重負荷的能力及長期的精度壽命。

2. Z軸226 mm方型滑枕搪孔軸採硬軌配Turcite B結構,VTC1612-CW標準行程900mm。

3.底座、立柱、橫樑、工作台等大型鑄件依製造需要,經由最新的3D設計,剛性最佳化,並以

多年經驗訂定有效的退火程序以消除殘餘應力,多年實際應用經驗,確實能達成有效的長期精

度保持性。

4.X、Z軸標準配備採用「雙編碼器」的「雙」半閉環回饋系統,經濟有效的提高各軸的定位精度。

(X、Z軸可選購德國Heidenhain或西班牙FAGOR光學尺)。

5.VTC-CW標準刀庫容量為16P(16儲位),車刀型式及分配數目可依客戶要求處理。

6.主軸箱等關鍵零件係利用自有的「大型臥式鏜孔機」及「大型高精度三次元量測儀(三座標量床)」

確實達成應有的加工精度,確保優良的組裝基礎。

7.承襲歐美先進工具機廠的標準,以嚴格維護的「1.2米x1.2米」高精密度的方形標準平板做為精密

精度的基礎,對各項關鍵零件進行精密鏟花(刮研),使機器的各處結合面和滑動面均能達到正確的

幾何精度,確保機器應有的精度和壽命。

8.搭配高規格的Fanuc數控系統,標準功能包含:15吋彩色液晶螢幕、Fanuc全鍵式操作面板、

2MB記憶容量、Ethernet網路接口、Flash記憶卡插口、剛性攻牙及各種特殊補間(插補)等多項

高規格功能,能經濟有效的滿足各種使用需求。

9.採用的各項配套零組件均經過長期使用驗證,可確保機器長期運行的可靠性。

10.完整的品檢測試流程,搭配先進的自動光學直準儀、雷射干涉儀、球桿檢測儀、線上動平衡儀等

精密檢測儀器,確保出廠的機器都能達到設計的性能和應有的功能。

11.經驗豐富的研發團隊,突破老舊的包袱,協助客戶達成各種特殊需求。

12.兼具經驗和熱誠的服務團隊和完整的服務體系,可以及時有效的讓用戶的機器長保最佳使用狀態。