Theme

Digital Transformation

Green Transformation

HEIDENHAIN CO., LTD. (TAIWAN)

Product Description :

Angle encoders for rotary and tilting axes are indispensable for machine tools on which high positioning accuracy and a high machining rate are essential. Because angle encoder measure angular motion of the axis directly and immediately. Mechanical transfer elements therefore have no influence on position measurement, both kinematics errors and the influences of forces are measured by the angle encoder and considered in the position control loop. This can eliminate a number of potential error sources: Gear errors, reversal error, errors due to deformation of the drive mechanics by machining forces.

NUMEN MACHINERY CO., LTD.

Product Description :

*High-rigidity structure design, using C3 precision ball

screw for axial feed and direct drive with servo motor.

* X/Y/Z axes installed with roller type of linear slide way

to ensure rigidity of axial movement and fast feed rate.

* Direct drive spindle.

* Suitable for various processing industries.

* 4th axis / 5th axis applications.

HO CHEN MACHINERY & ELECTRIC IND. CO., LTD.

Product Description :

X axis travel:

Single movement: 1125 mm (44" )inch

Dual movement: 560 mm (22") inch

YZ axis travel 700x500 mm (28"x20") inch

Work table: 1850x850 mm (73"x33") inch

Max. Workpiece: 2800x1400x700 mm (110"x55"x28") inch

Max. Workpiece weight: 5800 kg

Max. electrode weight: 400 kg

Machine net weight:8350 kg

Oil level: 110-550 mm (4"-22") inch

Packing size(LxWxH): 5430x4600x3090 mm (214"x181"x122") inch

Work Table to platen: 700-1200 mm (28"-47") inch

Filter: 4

Paper filter:8

Capacity:3400 Liters

Machine Features

> Windows CE controller

> A dialog window with picture description.

> Special repaired frames to quicken the maintenance speed.

> Close-loop design of digital feedback on three axes of the machine significantly increases positioning precision and ORBIT-CUT machining accuracy and efficiency.

> Simple operation interface.

> Common function keys are located on the operational panel for direct use.

> Hot key setting.

> ATC (automatic tool change) and C-axis 360° index can be installed; the process of coarse machining to ultra-fine machining can be completed at one time.

> Dialogue diagram provides various hole-expanding modes such as quick search of edge, centers and datum marks.

> Rich color graphic (the same resolution as a PC screen).

> Automatic multi-step machining (coarse, medium coarse, medium fine, fine, superfine)—up to 10 steps.

> Unlimited number of machining conditions can be saved as machining archives. Each set of machining conditions can be edited, modified or stored. They are easy to edit and easy to find.

> Automatic origin search and multi-point coordinate memory capability.

> 1/2 design capability, ARC automatic discharge waveform detection and automatic adjustment.

> Automatic center position detection, automatic compensation, search of hole center and deepest point; fixed hole machining (cyclic mode, independent mode), which is suitable for different machining conditions; Radial, circular, square, linear (vector), coning, 45° hole-expanding machining.

> Three-axis beeline, two-axis arc, three-axis helix.

> Chinese/English versions interface, metric/British system switch and Z-axis quick up, quick down, slow up and slow down capability.

> Lateral machining, three axes, six directions (plane rotation).

> All alarms describe the source, date and exact time of problem occurrence.

> Optical scale is applied for close-loop position control, enabling extreme position for machining.

> Automatic editing—settings can be done according to type of material, work piece size, machining depth, one side die clearance, final current and rate of electrode wear.

> CNC models possess conventional capability of consistent level of energy discharge, achieving stable and rapid machining and smooth high quality on machining surface while the rate of electrode wear is still low.

> Monitor page indicates machining path and orbital pattern in use.

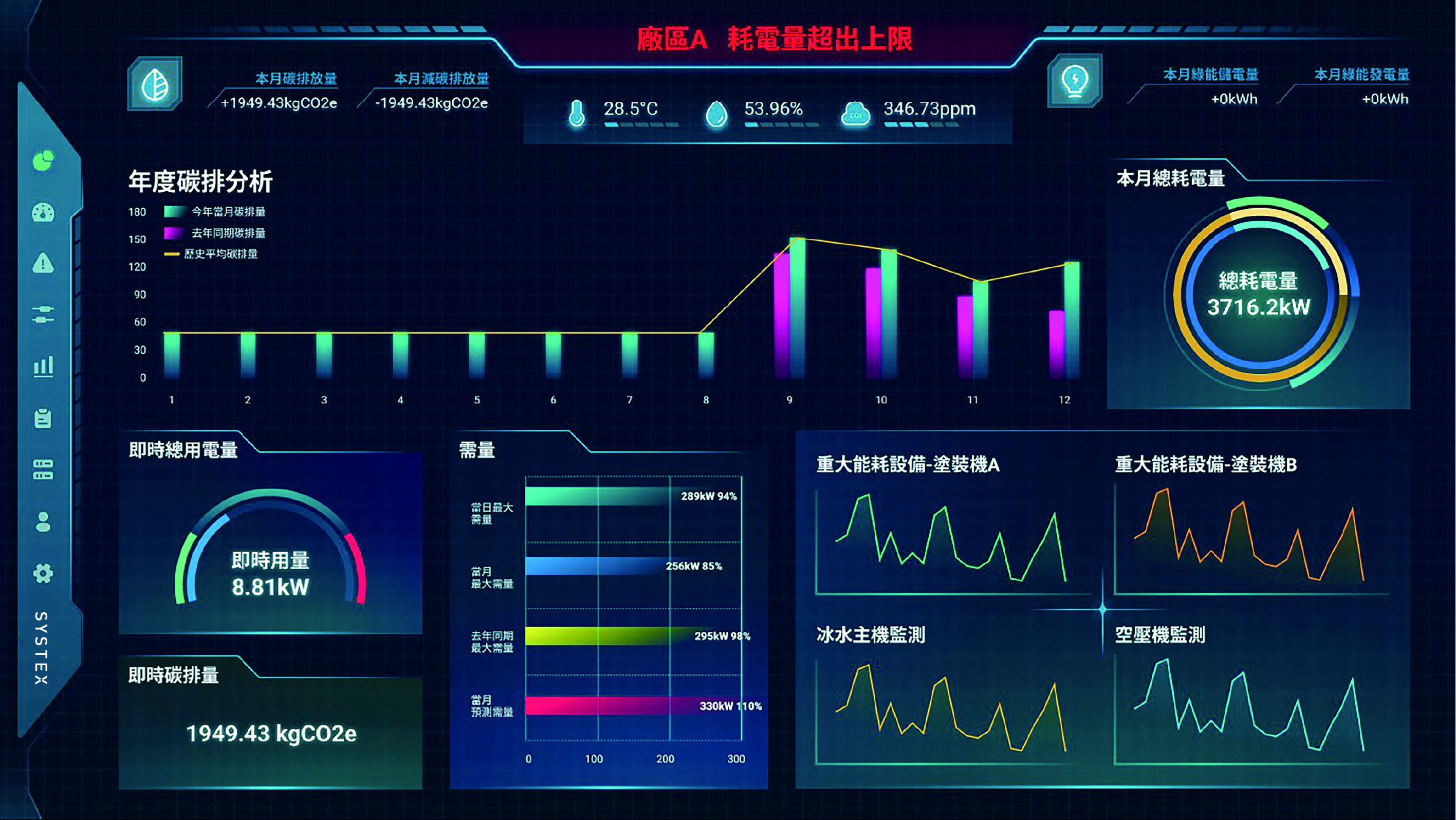

Administration for Digital Industries, moda

Product Description :

Taifon Computer Co., Ltd. provides the EnVision360 Energy Management Platform, enabling real-time electricity monitoring, that helps users monitor demand response and detect electrical anomalies through data visualization with power consumption trends.

By utilizing this cloud-based energy management platform in conjunction with smart meters, it is possible to establish energy baselines, calculate energy efficiency index, and effectively manage energy consumption with ease.

CHIEN CHENS MACHINERY CO., LTD.

Product Description :

Specification

Table size: 1515 x 470 mm

Longitudinal travel: 1300 mm

Cross travel: 600 mm

A axis travel: 370 mm

Y slide way width: 720 mm

Z Slide high: MAX 700 mm

Z Slide way width: 420 mm

Spindle taper: NT#40(BT)

Spindle motor: 5HP / 4P

Spindle speed: 70~3600 RPM

Horizontal Spindle motor: 5HP / 4P

HorizontalSpindle speed: 70~3600 RPM

Feeding speed: 10~6000 mm/min

Ballscrew: Ø32 mm C5

Net weight: 3500 kgs

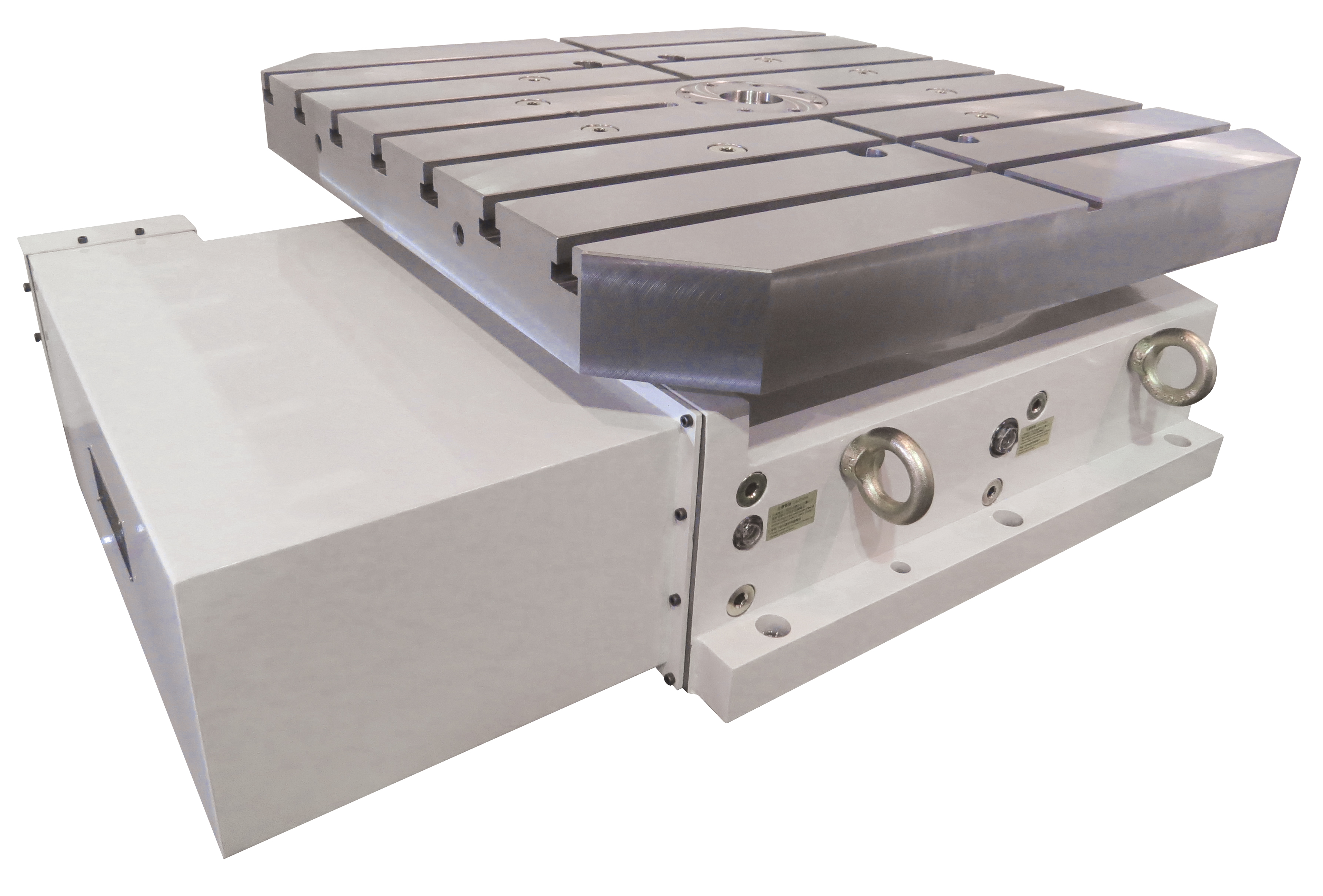

GSA TECHNOLOGY CO., LTD.

Product Description :

Suitable for Horizontal Machining Center,floor type boring machine。

High Accuracy,Adapting a special anti-wearing alloy of bronze/nickel double-lead worm wheel and hardened steel worm scrrew ensure long term indexing accuracy。

Table size from size 400mm to 2500mm or manufactured manufactured according to customer's designing and interface of machine Saddle。

Hydraulic Clamping,high rigid brake structure for heavy cutting。

Build-in hydraulic ports system suitable for Special Machine of Horizontal machining Center and Automobile/Motorbike Industrial。