Theme

Digital Transformation

Green Transformation

G-TECH INSTRUMENTS INC.

Product Description :

The performance of the spindle is an important key to processing quality. When you understand the performance of the spindle, you can predict and control the quality of the processed parts. The shape accuracy, roundness, and surface roughness of the workpieces are all related to the performance of the spindle. Only when the spindle is real measuring the accuracy of the spindle at the processing speed of the machine has meaning to the control of the quality of the processed parts, so measuring and understanding the performance of the machine tool, finding the best working speed, determining the warm-up time, even confirm the accuracy of the spindle after the collision.

LION provided this SEA analysis system as early as 1993 to help spindle manufacturers, machine tool factories and processing plants to reduce workpiece defect rate and improve product quality.

★The SEA system complies with the following international standards:

✓ ANSI / ASME B5.54-2005: "Methods for Performance Evaluation of CNC Machining Centers"

✓ ISO230: Test Code for Machine Tools, 3: "Determination of Thermal Effects" 7: "Geometric Accuracy of Axes of Rotation"

✓ ANSI / ASME B5.57-1998: "Methods for Performance Evaluation of CNC Turning Centers"

✓ ANSI / ASME B89.3.4: "Axes of Rotation, Methods for Specifying and Testing"

7-LEADERS CORP.

Product Description :

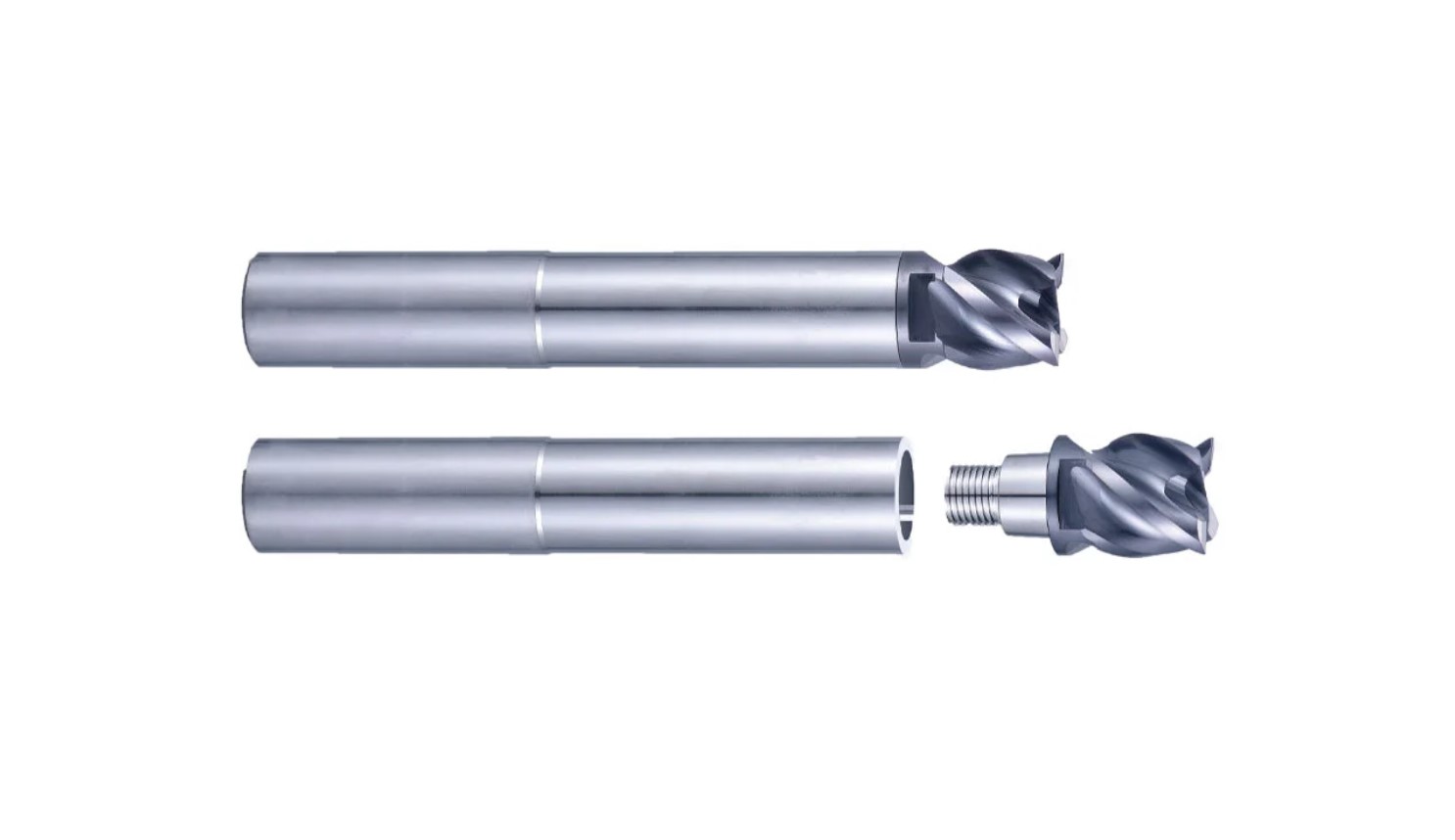

Multipurpose End Mills with Corner Radius- 4 Flutes

Using UMG carbide material enable to enhance lubrication and wear resistance.

Effectively decrease the vibration by various helix geometry and unequal flutes designs.

Big chip breaker is designed to reach high removal rate for various work materials.

Cutting edge with corner radius design and nano multilayer coating AlCrN are suitable for carbon steel, alloy steel and stainless steel with impurities and sticky materials.

Suitable for various kinds of work materials from the end of roughing to finishing.

HOLDING ELECTRIC CO., LTD.

Product Description :

The magnetic grinding machine is an innovative product of Holding Electric, and has won invention patents from many countries in the world

This patented device generates a magnetic field that motivates magnetized pins to bounce rapidly and to grind parts

Features

1.For High Precision

2.Grind Every Corner:

Effect

1.Deburring

2.Polishing

JAINNHER MACHINE CO., LTD.

Product Description :

The aesthetic design of JHT-4010 will convince you, as well as the technology of the fast-moving hydrostatic guideway system.

The 3500rpm built-in spindle, the ability to carry a Ø510mm grinding wheel, and a wheel head axis capable of rotating ±30° for thread grinding are impressive features enabling you to move your manufacturing to a new level.

Jainnher's officially website:www.jainnher.com

Jainnher's Youtube:

https://www.youtube.com/user/GrindingMachineTech/videos

ADLEE POWERTRONIC CO., LTD.

Product Description :

Product applications:

Internal & External grinder 、Conveying equipment、Coffee roasting equipment、Centrifugal equipment、Polishing equipment、Emulsifying machine、Glass edge grinder、Auto polisher grinder, etc.

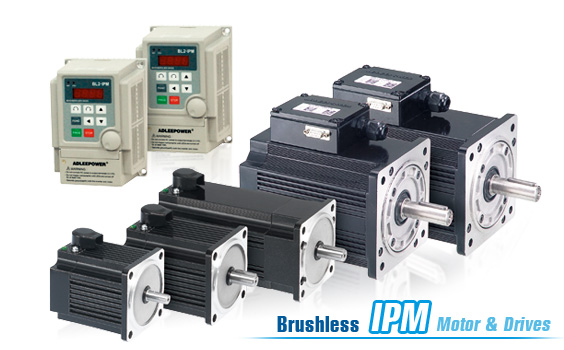

Brushless DC Motor

1. Minimize EMI and maintenance free. Low noise.

2. Specialized design to have smooth shaft rotation and improved reliability.

3. Brushless DC motor is light weight and compact size, higher power density, higher torque density and higher efficiency than conventional motors.

4. The structure has an excellent behavior in energy saving during heavy load operation. The high efficiency range is much wider than other motors too.

5. Built-in NTC thermal resistor to prevent over heat problem.

AC Driver

1. Available for all control interfaces, ex. RS 485, direct signal, PLC, HMI.

2. Convenient 220VAC driver power input from 60W. No more 24VDC power supply.

3. Built-in 24VDC mechanical brake control power.

4. Real motor speed display and signal output.

5. Panel control is always enabled with removed control or terminal control or RS485 control. Convenient for system set up or maintenance.

6. Excellent speed stability. Open loop and close loop speed control for selection.

7. With 0~5VDC, 0~10VDC and 4~20mA speed analog input.

8. Over current / heat / voltage, electric motor lock protection.

YI CHANG MACHINERY CO., LTD.

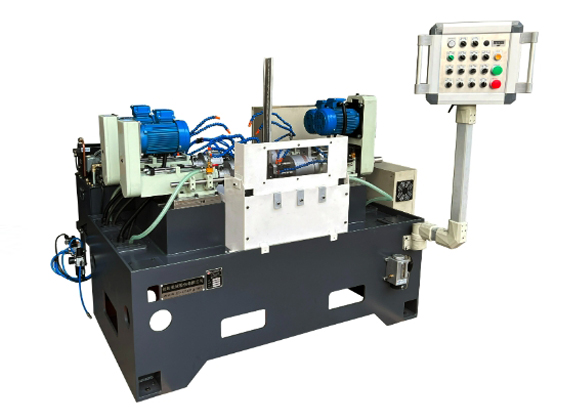

Product Description :

Linking a made horizontal Unith drilling machine and tapping machine with a hydraulic sliding table, assemble with an automatic loading and unloading system, enables rapid completion of drilling, tapping, and double-sided chamfering tasks.

This setup saves labor and allows precise control of relative positions.

If you have any thoughts or inquiries about our machine, please leave a comment below or call our company. We look forward to engaging and communicating with you!

VISION WIDE TECH CO., LTD.

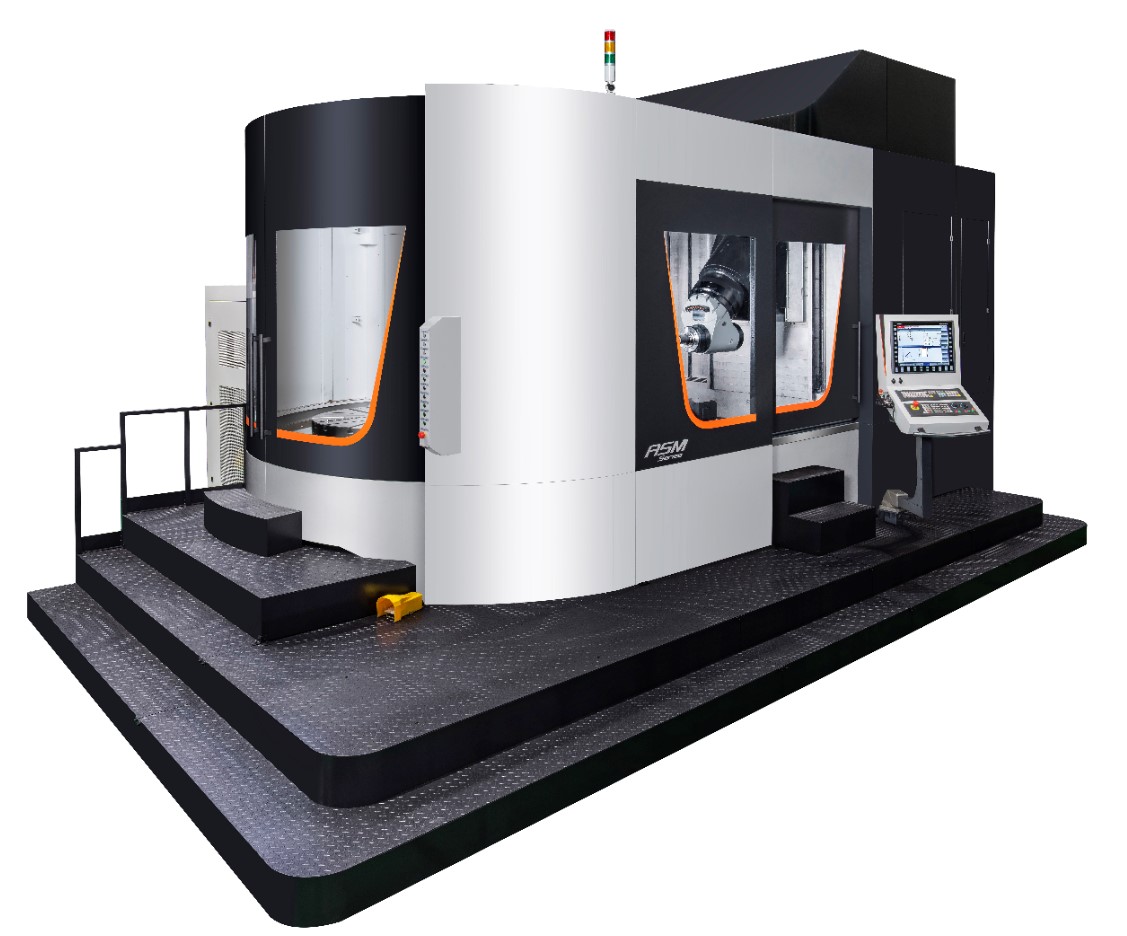

Product Description :

• ASM is the first 5-axis CNC turning and milling machining center of Vision Wide, and it is particularly designed for delicate cylindrical components machining featuring high acceleration, rapid feed-rate and synchronized axes machining, especially for aerospace components, tire molds, turbine blades and aluminum parts.

ASM accessorizes with 5-axis universal head and rotary shafts built-in D.D motor. Through topology analysis, ASM realizes the best distance between tool center point and B-axis transmission

• Positioning P0.006mm

• Repeatability Ps0.0055mm

• Spindle thermal compensation 0.02 mm

• Rapid Traverse 40m/min

• Acceleration 0.3G

• Cutting Feed rate 24 m/min