Theme

Digital Transformation

Green Transformation

JIN LI CHENG CUTTING TOOL CO., LTD.

Product Description :

※ We design and manufacture "speci c industry" tools

with fast delivery and great quality.

※ It can be designed according to the highest standard

and speci cation from customers. Flexible manufacturing

and accept customized tolerance.

※ From concept to nal completion. JLC customized

tools will reduce the cutter exchange labor time and

improve the e

ciency of mass production.

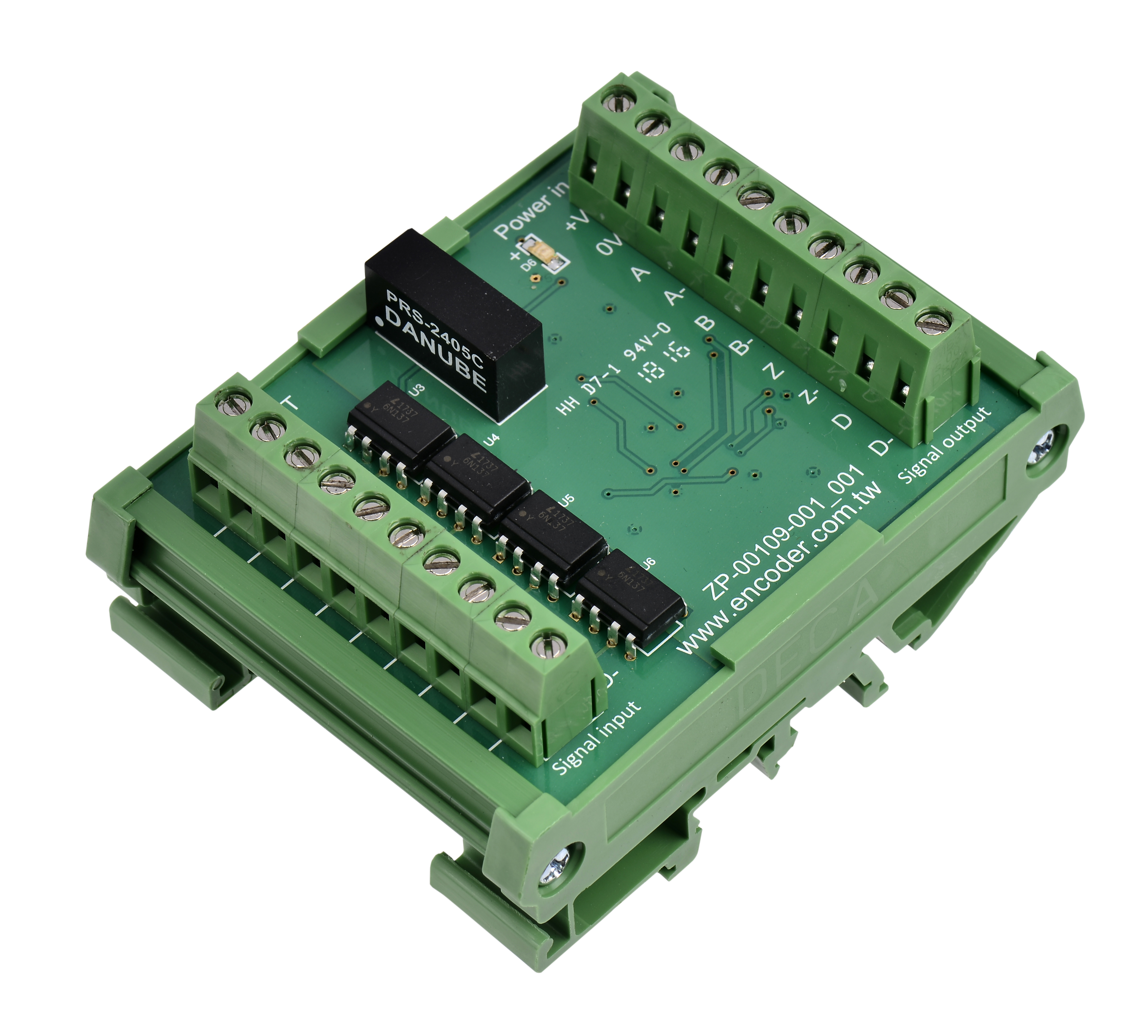

JASON AUTOMATION CO., LTD.

Product Description :

From the robust aluminum square profile, the versatile EcoShape round tubes, through to linear guides and a wide range of connection solutions: The Bosch Rexroth modular profile system currently includes more than 1,500 modular components for all areas of your production – even for ESD, clean and dry room applications. All components are finely coordinated and offer you an almost infinite number of combination possibilities when designing your working environments.

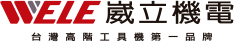

HO CHEN MACHINERY & ELECTRIC IND. CO., LTD.

Product Description :

X axis travel:

Single movement: 2550 mm (100") inch

Dual movement: 1275 mm (50") inch

YZ axes travel: 850x600 mm (33"x24") inch

※Y axis can be increased to 1300 mm(51") (Option)

※Z axis can be increased to 1000 mm(39") (Option)

Work table: 3100x1600 mm (122"x63") inch

Max. Workpiece: 4100x2050x1250 mm (161"x81"x49") inch

Max. Workpiece weight: 22000 kg

Max. electrode weight: 500 kg

Machine net weight: 29410 kg

Oil level: 110-1000mm (4"-39") inch

Occupy size(LxWxH): 6480x6600x4600 mm (255"x260"x181") inch

Work Table to platen:

600mm Z travel machine: 1138-1738mm (45"-68")

1000mm Z travel machine: 740-1740mm (29"-69")

Filter: 4

Paper filter:8

Capacity:11300 Liters

Machine Features

> Windows CE controller

> A dialog window with picture description.

> Special repaired frames to quicken the maintenance speed.

> Close-loop design of digital feedback on three axes of the machine significantly increases positioning precision and ORBIT-CUT machining accuracy and efficiency.

> Simple operation interface.

> Common function keys are located on the operational panel for direct use.

> Hot key setting.

> ATC (automatic tool change) and C-axis 360° index can be installed; the process of coarse machining to ultra-fine machining can be completed at one time.

> Dialogue diagram provides various hole-expanding modes such as quick search of edge, centers and datum marks.

> Rich color graphic (the same resolution as a PC screen).

> Automatic multi-step machining (coarse, medium coarse, medium fine, fine, superfine)—up to 10 steps.

> Unlimited number of machining conditions can be saved as machining archives. Each set of machining conditions can be edited, modified or stored. They are easy to edit and easy to find.

> Automatic origin search and multi-point coordinate memory capability.

> 1/2 design capability, ARC automatic discharge waveform detection and automatic adjustment.

> Automatic center position detection, automatic compensation, search of hole center and deepest point; fixed hole machining (cyclic mode, independent mode), which is suitable for different machining conditions; Radial, circular, square, linear (vector), coning, 45° hole-expanding machining.

> Three-axis beeline, two-axis arc, three-axis helix.

> Chinese/English versions interface, metric/British system switch and Z-axis quick up, quick down, slow up and slow down capability.

> Lateral machining, three axes, six directions (plane rotation).

> All alarms describe the source, date and exact time of problem occurrence.

> Optical scale is applied for close-loop position control, enabling extreme position for machining.

> Automatic editing—settings can be done according to type of material, work piece size, machining depth, one side die clearance, final current and rate of electrode wear.

> CNC models possess conventional capability of consistent level of energy discharge, achieving stable and rapid machining and smooth high quality on machining surface while the rate of electrode wear is still low.

> Monitor page indicates machining path and orbital pattern in use.

MING YANG MACHINERY CO., LTD.

Product Description :

This multi-tasking turning center is an advanced machine designed to process precision complex parts in one setup.

Power & Versatility: It has Double Spindles, a VDI/BMT 12 station Turret and a 2nd Y-Axis for back machining with 14 tools for a total capacity of up to 38 tools. This solution with superimposed cutting is a powerful combination of precision and two Y-axes for machining of complex workpieces with extremely fast cycle times.

Front Machining: BMT45 12-Stations, Up to 24 tools, 7.5/11 kW Spindle Power, 55 mm Through Hole.

Back Machining: Gang Tools Slide: 14 Tools, 3 Cross Live Tools, 3 Face Live Tools, 3 OD & 5 ID Tools.

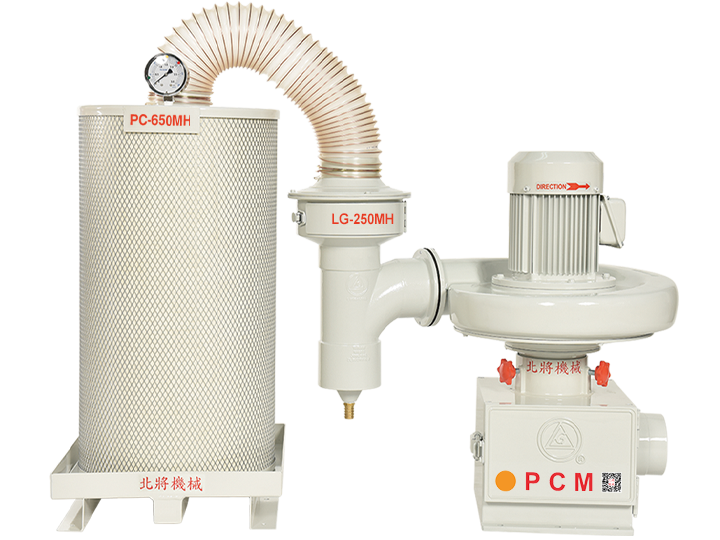

HOMGE MACHINERY IND. CO., LTD.

Product Description :

• Full set of this vise is made of Tool Steel with heat treatment more than HRC 60º of hardness and then ground precisely to ensures durability.

• HRV Vise is an adjustable vise, any shape of working piece, such as square, round, cylindrical or irregular shapes can be positioned quickly.

• This vise is suitable for Horizontal/Vertical and 4-Axis CNC Machining Centers, Surface Grinders,... etc.

CIMer Tech co.,Ltd.

Product Description :

Distributed data management

Store, protect and deliver your most important messages

CIMer is a system specially built for the period from product development to mass production. From business orders, CAD product design, material creation, process review, and project management, it can be tracked and searched through any device. As long as you have a browser, you can Can participate in inspection and review of product design and development work.

system structure

Each region establishes its own Vault Server, and files will be synchronized between Vault Servers. Users can access the local Vault Server when accessing files. Users do not need to obtain the original CAD drawing files. CIMer provides converted graphics viewing formats (3D HTML/2D PDF), which can reduce the consumption of web page resources during viewing and improve transmission efficiency....

project management

Provide dynamic information on multi-project management at each stage during product development, such as Gantt charts, to assist the product development team in focusing on product development and improvement, and provide relevant timetables, human resources, output overview and distribution development periods during the period. , achieve better planning and utilization.

Design data and graphics management

Multi-CAD integration platforms, including drawing configuration, properties, versions, version management, combined drawing structures, parts and specifications/file associations of AutoCAD, zwCAD, Creo, Solidworks, Solid EDGE, Inventor, ZW 3D, NX, CATIA, etc., such as Approving documents, document version management, HTML format model viewing, 2D PDF document viewing, sharing drawings, BOM information based on design combination drawings...

Material Management Parts BOM/EC

After the product drawing design is completed, it enters the engineering proofing stage and related material information collection and management. Drawing files, material number correspondence, material attribute management, version management, association and viewing of materials and files, material BOM, automatic generation of material numbers, shared materials, etc...

Sign-off process management

Provide process system customization, and allow multiple people to collaboratively review all work that requires mutual notification, recognition, and review during the product development process. It is used at the review and notification level of the process and can be flexibly applied to the work processes of different departments and personnel.

Network collaboration

CIMer Web provides data viewing in non-Windows environments and implements the basic principles of ESG. Any device with a browser can participate in online process progress, such as inspection and review of product design and development work, paperless factory, post-engineering EC design change management from direct access of design drawings to manufacturing cells...

Message Center

Similar to the Outlook mail management function, it provides a message management center to manage notification messages, quickly jump from messages to related project work, and at the same time send emails to the mail server...

Over 20 years of experience in CIMe system development.

Over 300 case studies.

Visited more than 1,000 customer needs.

More than 200 customer satisfaction cases.

The CIMer system helps shorten your product time to market and significantly saves production costs and hidden losses.