Theme

Digital Transformation

Green Transformation

HUI BAO ENTERPRISE CO.,LTD

Product Description :

In FRL combination category, Hui Bao provides five categories products which are all essential parts to an efficient air system. The five categories product comprise – Filter、Regulator、Lubricator、Air cleaner / dryer、Auto Drains. In terms of product range for FRL, we have 1/8” ~ 1” port sizes, which can fulfill requirements from the consumer level through industrial applications.

JIN LI CHENG CUTTING TOOL CO., LTD.

Product Description :

向全球使用金利成刀具的加工航太客戶,深深感謝。

JLC為全球客戶開發了多款加工鈦與WASPALOY及鎳基材料的經典刀款,獲得客戶的持續讚賞與肯定,我們也因為航太客戶的持續互動,一直追求創新與進步。

航空零部件不僅採用了很多新結構、新技術和新材料,零件也越來越講求精密與材料合適性。為了讓客戶在航太的加工上,有更多元的因應方式,我們正式推出新設計的航太特殊材料用刀– AP系列。

整體子彈流動力學的設計理念,與一貫的優質歐系棒材,再搭配更勝一般鈦矽的複合及類鑽鍍層,經過廠內多次的實驗,AP航太系列刀具,絕對讓您面對航太材料加工上游刃有餘。

歡迎全球客戶指教,金利成再次感謝您的支持。

Lotus Business Information Co., Ltd.

Product Description :

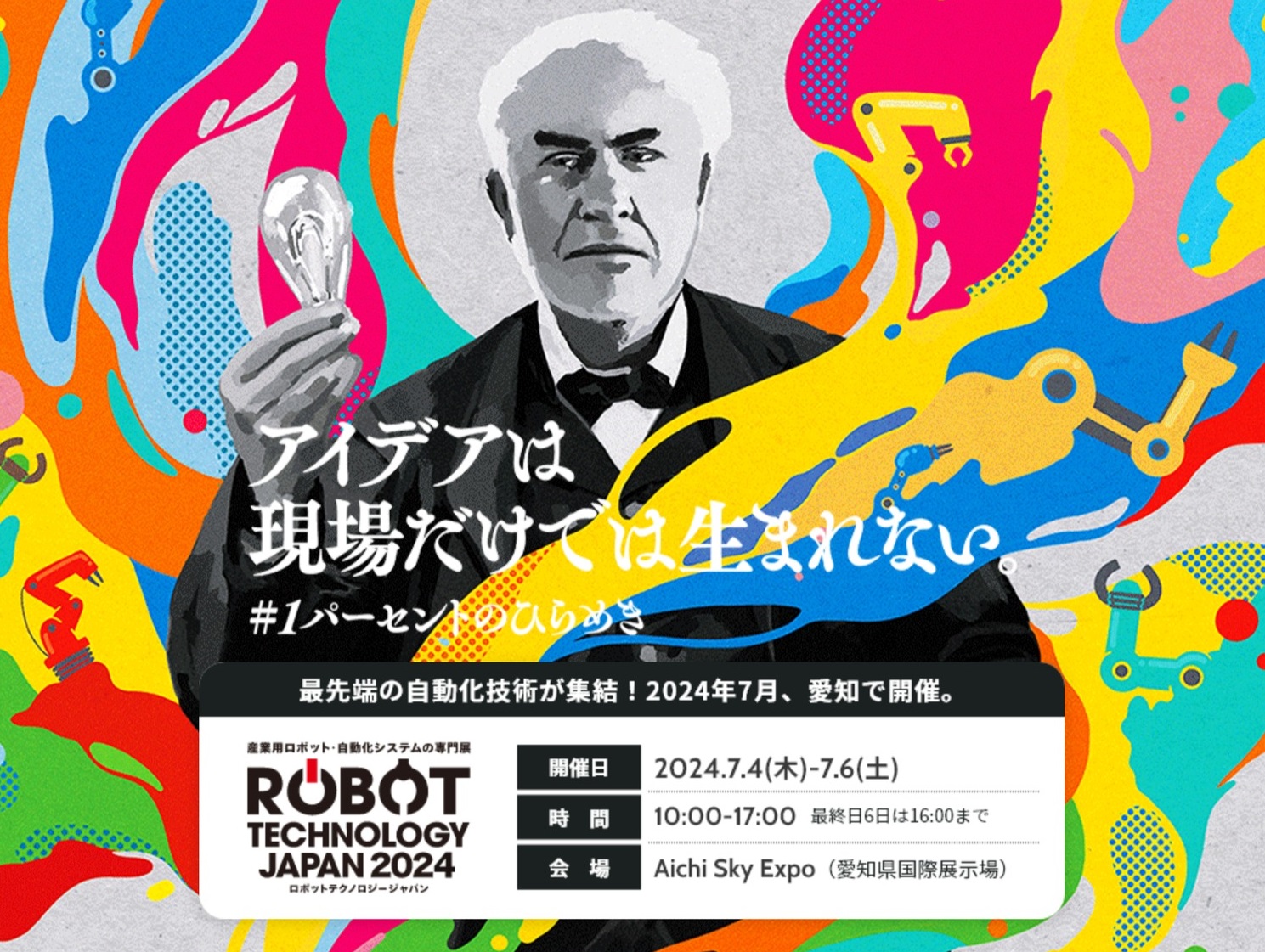

This is one of the biggest B to B exhibitions held in “Central Japan,” an industrial area with a cluster of manufacturers. In 2022, 202 companies with 1,096 booths were registered in the exhibition.

The scope of the exhibition is specialized in “industrial robots” used in manufacturing sites and logistics bases, “devices and equipment” with industrial robots integrated in them, and “automation systems” using like AGVs/AMRs.

GP MACHINERY CO., LTD.

Product Description :

Features:

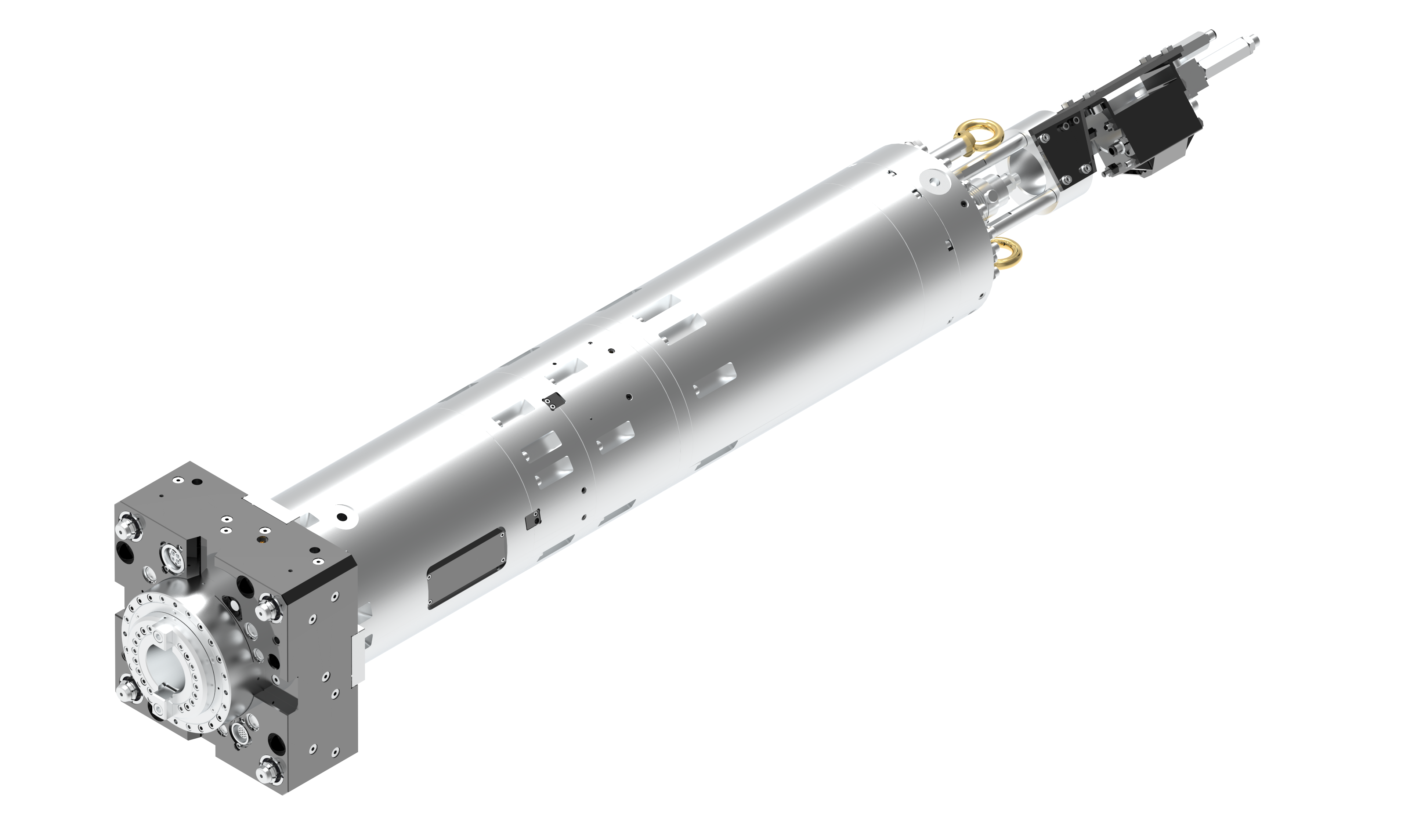

The RGB system (Ram Gear Box) is the most complete solution within this family, with important technological contents, that combines high torque performance in small dimensions particularly appreciated for vertical (gantry or double column) and horizontal axis machine tools. The general characteristics are similar to the RTS

Products:

.Automatic attachment system for the accessories (like heads or extensions)

.Multitasking machining operations.

.Easiness of assembly and maintenance on the machine with:

.Quick connections and couplings positioned at the top of the RAM

.Possibility of easy and quick extracion of the spindle from the front of the RAM.

YA LIANG INDUSTRIAL CO., LTD.

Product Description :

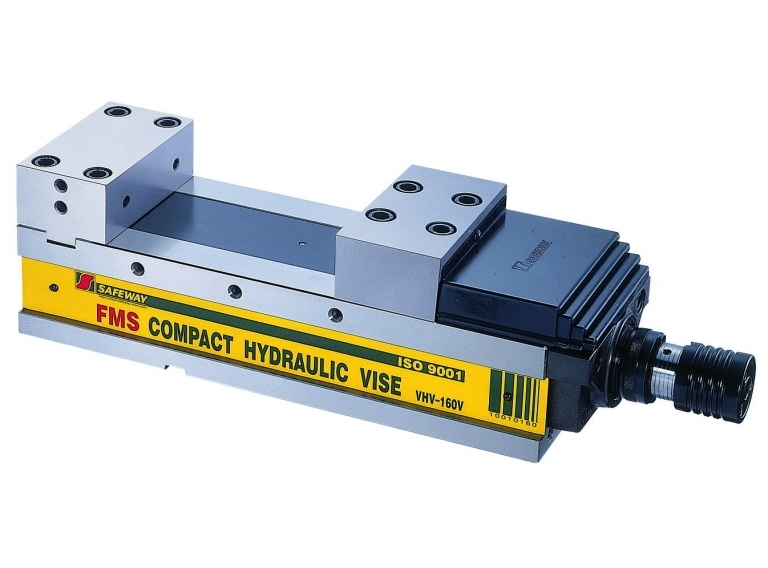

S-TYPE Special heavy duty model #122

Extremely high accuracy and precision design, suitable for CNC machining and machining center. All parts are ground, heat treated, surface treated and under specific QC condition.

H-TYPE Heavy duty model #123

Industrial design especially for milling machines and drilling machines.

All hardened parts ensure long life and safety while in operation.

HO CHEN MACHINERY & ELECTRIC IND. CO., LTD.

Product Description :

X axis travel:

Single movement: 2550 mm (100") inch

Dual movement: 1275 mm (50") inch

YZ axes travel: 850x600 mm (33"x24") inch

※Y axis can be increased to 1300 mm(51") (Option)

※Z axis can be increased to 1000 mm(39") (Option)

Work table: 3100x1600 mm (122"x63") inch

Max. Workpiece: 4100x2050x1250 mm (161"x81"x49") inch

Max. Workpiece weight: 22000 kg

Max. electrode weight: 500 kg

Machine net weight: 29410 kg

Oil level: 110-1000mm (4"-39") inch

Occupy size(LxWxH): 6480x6600x4600 mm (255"x260"x181") inch

Work Table to platen:

600mm Z travel machine: 1138-1738mm (45"-68")

1000mm Z travel machine: 740-1740mm (29"-69")

Filter: 4

Paper filter:8

Capacity:11300 Liters

Machine Features

> Windows CE controller

> A dialog window with picture description.

> Special repaired frames to quicken the maintenance speed.

> Close-loop design of digital feedback on three axes of the machine significantly increases positioning precision and ORBIT-CUT machining accuracy and efficiency.

> Simple operation interface.

> Common function keys are located on the operational panel for direct use.

> Hot key setting.

> ATC (automatic tool change) and C-axis 360° index can be installed; the process of coarse machining to ultra-fine machining can be completed at one time.

> Dialogue diagram provides various hole-expanding modes such as quick search of edge, centers and datum marks.

> Rich color graphic (the same resolution as a PC screen).

> Automatic multi-step machining (coarse, medium coarse, medium fine, fine, superfine)—up to 10 steps.

> Unlimited number of machining conditions can be saved as machining archives. Each set of machining conditions can be edited, modified or stored. They are easy to edit and easy to find.

> Automatic origin search and multi-point coordinate memory capability.

> 1/2 design capability, ARC automatic discharge waveform detection and automatic adjustment.

> Automatic center position detection, automatic compensation, search of hole center and deepest point; fixed hole machining (cyclic mode, independent mode), which is suitable for different machining conditions; Radial, circular, square, linear (vector), coning, 45° hole-expanding machining.

> Three-axis beeline, two-axis arc, three-axis helix.

> Chinese/English versions interface, metric/British system switch and Z-axis quick up, quick down, slow up and slow down capability.

> Lateral machining, three axes, six directions (plane rotation).

> All alarms describe the source, date and exact time of problem occurrence.

> Optical scale is applied for close-loop position control, enabling extreme position for machining.

> Automatic editing—settings can be done according to type of material, work piece size, machining depth, one side die clearance, final current and rate of electrode wear.

> CNC models possess conventional capability of consistent level of energy discharge, achieving stable and rapid machining and smooth high quality on machining surface while the rate of electrode wear is still low.

> Monitor page indicates machining path and orbital pattern in use.

BLUM PRODUCTION METROLOGY CO., LTD.

Product Description :

• Measuring speed up to 3 m/min

• Precise, non-lobing touch characteristics

• No-wear, optoelectronic measuring mechanism

• Use of two measuring systems with one IR receiver

• Extended battery life

• Precise measurement even with coolant

• Proven and robust design