Theme

Digital Transformation

Green Transformation

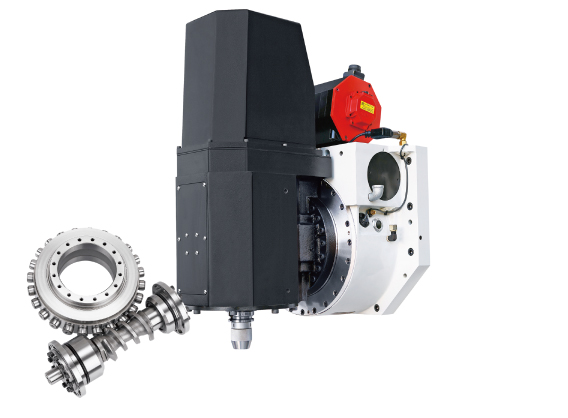

MANFORD MACHINERY CO., LTD.

Product Description :

VX-600 5-Axis Machining Center is designed for multiaxes machining of small and large series of complex 5-side workpieces. With swiveling head and rotary table, VX-series is able to do simultaneous 5 axes machining with high accuracy.

High proformance swiveling head, tilting angle from -120 ~ +30 equipped with 15,000rpm built-in spindle.

VX-600/VX-600T is with an enbedded Ø 630mm diameter rotary table. Any complex workpiece can be accomplished with a single setup.

AUTOGRIP MACHINERY CO., LTD.

Product Description :

◎ Second Collet Changes Slash Setup Times.

◎ Industry-Leading Gripping Range.

◎ Ultra-Precision Accuracy.

◎ Parallel clamping over the entire clamping length

◎ Extreme Grip Force = Most Aggressive Chip Removal/Fastest Cycle Times.

◎ Maximum Rigidity Produces Superior Part Finishes.

◎ Best Tool Clearance - Critical For Live Tooling.

YIDA PRECISION MACHINERY CO., LTD.

Product Description :

1. T structure bed with high-quality cast-iron frame for enhanced rigidity and stability.

2. Extremely rigid mobile column with linear guide ways ensures stability and cutting accuracy while allowing rapid traverse of the X, Y and Z axes.

3. High rigidity roller type linear guideways, rugged massive linear guideways on X, Y and Z axes maintain precision and ensure a rapid traverse rate.

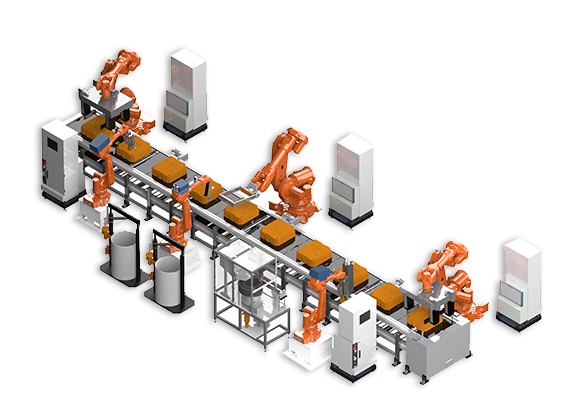

Go power machinery CO.LTD

Product Description :

Gutian horizontal cam fix-axis rotary table has internal cam roller transmission mechanism.

There is backlash-free rolling drive between cam and needle bearings pre-load, no sliding

friction or backlash. Its positive reverse motion has high repeatability accuracy without the

need for periodic calibration and adjustment. Its accuracy is not affected by rising

temperature. Improving the quality of multi-axis machining parts can greatly reduce defective

rate of machined parts.

MING YANG MACHINERY CO., LTD.

Product Description :

Twin spindle configuration allows for both front and back machining.

Equipped with Sauter Turret

•C-axis functionality on both main and sub-spindle.

•Y-axis functionality promotes side and face milling, drilling, and tapping.

•12-station live turret ensures efficient milling, drilling, and tapping.

•A2-5 spindle nose.

6000rpm high speed spindle.

•High precision spindle accommodates collect chucks and 3-jaw chucks.

•X, Z, Y-axis feed rates: 24/24/10 M/min

Hantop Intelligence Technology

Product Description :

Tool Holder Spec. provided:

BT30, BT40, HSKA63, HSKE25, HSKE32, HSKE40, CAT40

1. High Speed, high efficiency ultrasonic machining solution for high precision advanced materials machining(can reach 38000 rpm)

2. Plug and Play design for convenient and flexible Installation

3. Effective Intelligent Tracking System for advanced materials machining, finding the suitable resonance between tools and modules

4. Non-Contact transmission Design doesn't limit the high spindle rotation and reduce the impact from cutting heat, enhancing tool life and quality to next level.

YIDA PRECISION MACHINERY CO., LTD.

Product Description :

The Main characteristics of Turn-Mill machine MT-540 are the orthogonal structure and rotating mill head, offering C, Y and B turn-mill capacity.

The orthogonal structure design provides wide range of travel and high dynamic rigidity. Turning combined with mill head can cut simultaneously from different direction, reduce cycle time and improve parts accuracy.

Compact and flexible machine, the MT-540 comes with maximum bar feeding diameter of 65mm. The workpiece with maximum turning diameter of 350

mm and 700 mm length can be machined.

Multi-purposed rotating components offer versatile functionality, like tailstock, loading, milling and drilling, helping the operator in practical using and long

periods of unmanned running.

HAI JU TRADING CO., LTD.

Product Description :

螺紋護套, 是一種高強度的緊固件, 能在低強度的材料中提供高強度的緊固功能,螺紋護套已經在市場上發行約超過60年, 這些不銹鋼螺紋護套是以菱形輪廓的鋼線製成彈性螺旋, 並且經過質量驗證。護套安裝後,在導舌預定斷裂點折斷導舌,以使螺紋護套通孔.<br />

<br />

<br />

<br />

由於不斷的改良與優化,HELICOIL®Plus 螺紋護套 現在更容易安裝。<br />

<br />

與HELICOIL®經典螺紋護套做比較, HELICOIL®Plus的線圈有特殊的起始, HELICOIL®Plus同樣是以菱形輪廓的鋼線製成的彈性螺旋, 於由線圈有特殊的起始, 安裝時可以像螺絲一樣被定位並擰入, 搭配現有的同一公稱系列工具組裝,與HELICOIL®經典螺紋護套的安裝做比較, 能縮短將近20%的安裝時間. <br />

<br />

<br />

<br />

HELICOIL®Plus 提供高強力, 能從側面到側面, 將力傳遞到螺紋。<br />

<br />

這種高度可靠性的系統已被德國和國際工業產權提交。 HELICOIL®Plus根據一致性的材料和質量規範生產螺紋護套, 並滿足國家標準化以及航空和軍用標準的要求。 除此之外, 許多領先的大型用戶亦以HELICOIL®螺紋護套為基礎做為製造標準。<br />

<br />

<br />

<br />

<br />

<br />

Rm = tensile strength 1,400 N/mm2 min.<br />

HV = vickers hardness 425 HV 0.2 min.<br />

RZ = roughness depth approx. 2.5 μm<br />

μG = reduced thread friction, results in increased preload-force FV<br />

τt = reduction in torsion stress in the screw shank<br />

===========================================================<br />

<br />

HELICOIL®無尾螺紋護套<br />

<br />

1.無折斷,無斷裂<br />

-無風險的留在組件<br />

-減少安裝時間<br />

-減少測試時間<br />

<br />

2.降低刀具磨損<br />

-工具刀片的磨損最小<br />

-易於維護<br />

<br />

3.提高品質<br />

-簡單化的品量保證<br />

-高強度的配合螺紋盲孔深度或預裝配組件<br />

-符合NA0276標準