Theme

Digital Transformation

Green Transformation

HEIDENHAIN CO., LTD. (TAIWAN)

Product Description :

In addition to milling operations, the TNC 640 also combines operations from milling, turning, and grinding processes. This sets the TNC 640 apart as a high-end control within its field of application. It is particularly well suited to HSC and 5-axis simultaneous machining, including on fully automated machining centers. The TNC 640 stands for perfect surface quality, exceptional accuracy, and very short machining times combined with shop-friendly operation and programming. On a milling/ turning machine with TNC 640, you machine the complete work piece on one machine in whatever sequence is needed. You can switch back and forth regardless of the machine and its axis configuration. The TNC 640 makes all necessary adjustments, e.g. switching to diameter display and setting the datum in the rotary table center. Batch Process Manager allows you to optimally plan and execute production jobs with great ease. With Batch Process Manager you can flexibly define the sequence of your jobs and, prior to machining, check to ensure that all of the required tools are available and that the NC program will run without errors.

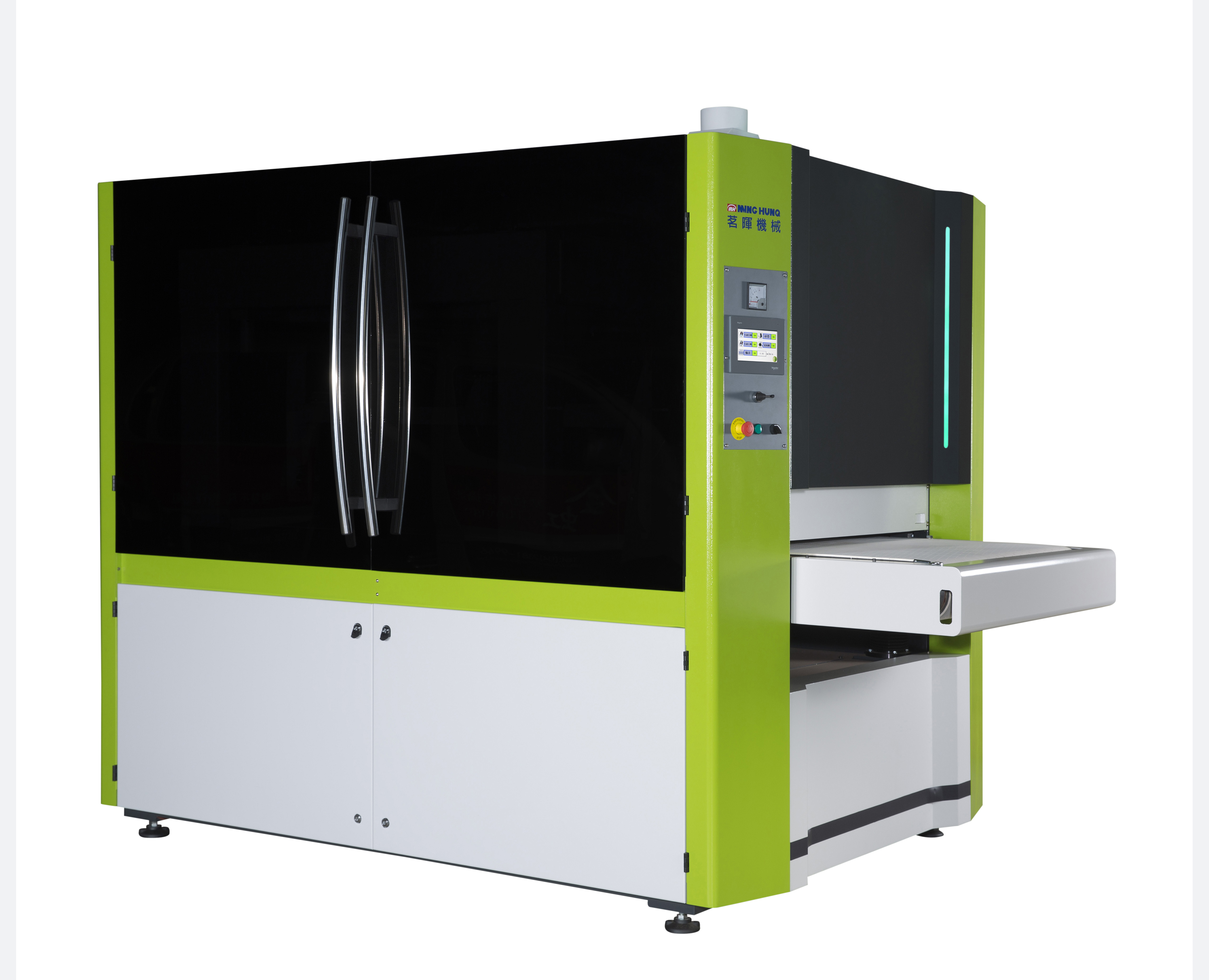

MING HUNQ MACHINERY CO., LTD.

Product Description :

GD-100 is a device that can serve your need for grinding and chamfering of sheet metal. Such as flame cutting, laser cutting, punching of the residue and bristles after stamping. All of the sharp angle of the edges and inner holes can easily be done on this machine.

YEONG CHIN MACHINERY INDUSTRIES CO., LTD.

Product Description :

NFX400A is designed especially for small, complex high-quality parts mainly for aerospace, automotive, medical, job shop and die & mold applications

■ Extra wide column and base design to ensure best support and cutting rigidity.

■ Increased tool life by cutting with belly and edge of the tool

■ Reduce fixture error and improve workpiece loading and uploading time

■ Greatly reduced non-cutting or setup waiting time

■ Saves manufacturing cost with reduced fixture and electrode costs.

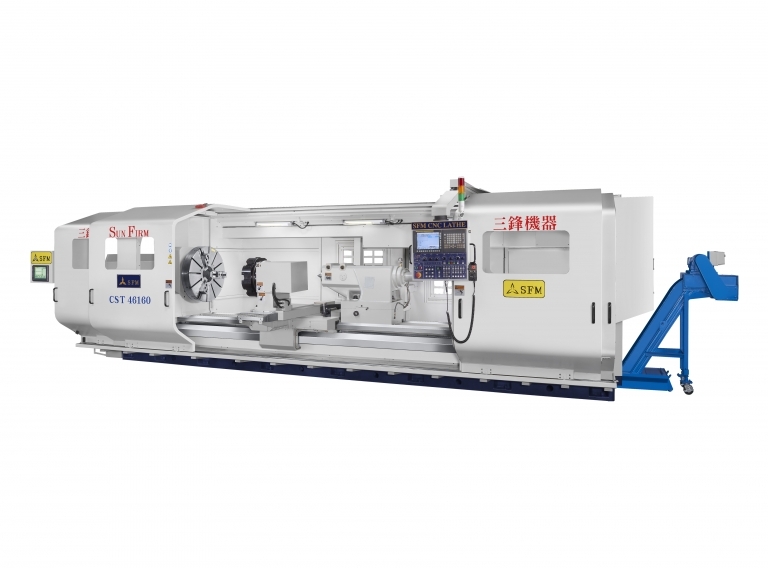

SUN FIRM MACHINERY IND. CO., LTD.

Product Description :

The latest Sun Firm CST-46160 is a horizontal CNC precision lathe offering high flexibility and processing efficiency. Our specially designed spindle accommodates up to two sets of mandrels at the front and back, which is perfect for processing long tubes or bars. The turret is designed to fit the rigid platform-type rail structure, providing the best balance between high cutting resistance and processing efficiency. The design of the body structure is complete and the interface is taken into account in advance. It can support the robot arm, the automatic power system as well as the power turret and lead to a more efficient treatment, bringing us win-win benefits.

CST-46160 is a very efficient machine that can meet all kind of requirements for multi-task and complex machining, shorten processing time and reduce part clamping errors. It can be installed with FANUC, SIEMENS, FAGOR control devices, satisfying customer's needs and becoming more user-friendly.

ASMITH MANUFACTURING COMPANY

Product Description :

High precision, durability, stability electronic torque wrench, torque range of 0.1~1000 Nm, accuracy guaranteed ±1%, MIT, Japanese specifications wafer can use 20 years. Factory measured 100000 times to lock still keep high precision. Suitable for metal machine tool, controller & computer system, precision industry, high tech & electronic industry, quality assurance & manufacturing dep. |Tube Material:Medium carbon steel|Grip Material:ABS|Series: Standard Electronic Torque Wrenches, Mini Digital Torque Wrenches, Digital Torque Adapters, Open-ended Insert tools