Theme

Digital Transformation

Green Transformation

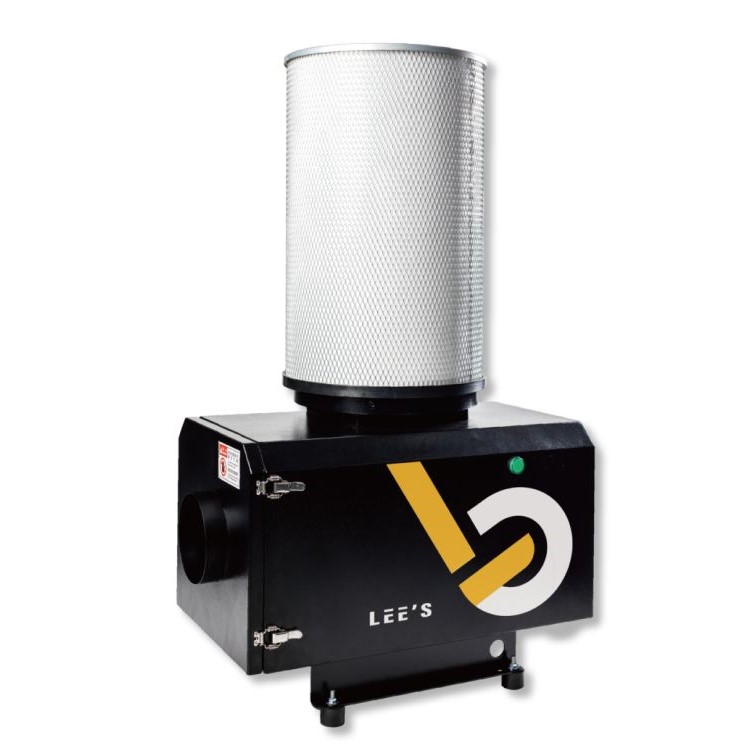

TOP POWER MACHINERY ENTERPRISE CO.

Product Description :

We exclusive patented technology and is committed to developing and producing products that meet global environmental protection goals. The machine is made of all metal and stainless steel materials. From the perspective of environmentally friendly equipment, it realizes the concept of net-zero and low consumables. Using the principle of physical centrifugation, a unique oil throwing device is designed, which can effectively extend the maintenance cycle and increase the filtration rate of oil smoke generated by the processing machine to more than 85%. In addition, the new generation design improves the performance of the machine with the same horsepower by 50%. Under the same efficiency, the power saving rate can be as high as 200% to 400%.

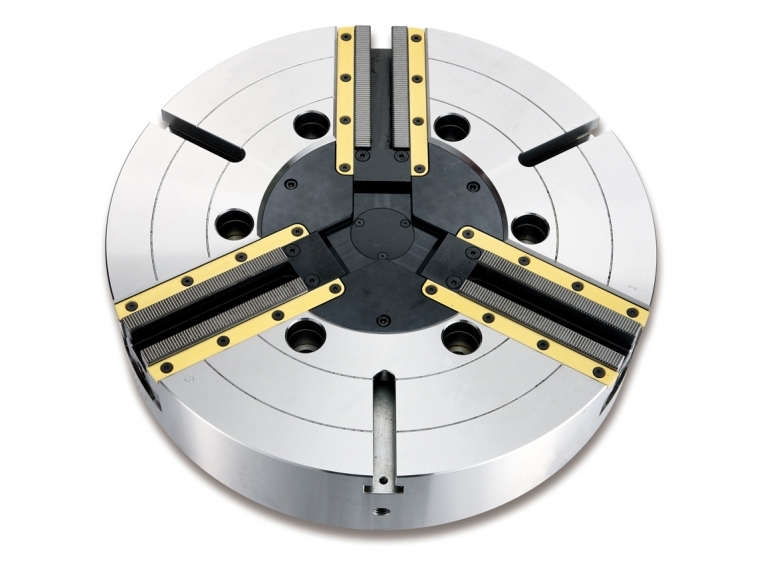

YANMECH Industrial Co., Ltd.

Product Description :

【A Series:】

1. The jaw can be individually operated, and irregularly shaped workpieces can be clamped.

2. Install side strips and chips cover sealed base jaw to prevent chips and coolant ingress.

【D Series:】

1. Install side strips and chips cover sealed base jaw to prevent chips and coolant ingress.

2. Adapter Plates can be selected.

3. The base jaw is lower than the body surface and can be used for multipurpose.

4. Alternative spindle adaptors:

ASA or DIN adaptors can be supplied as requested.

ADLEE POWERTRONIC CO., LTD.

Product Description :

●Brushless DC Motor

1. Minimize EMI and maintenance free. Low noise.

2. Specialized design to have smooth shaft rotation and improved reliability.

3. Brushless DC motor is light weight and compact size, higher power density, higher torque density and higher efficiency than conventional motors.

4. The structure has an excellent behavior in energy saving during heavy load operation. The high efficiency range is much wider than other motors too.

5. Built-in NTC thermal resistor to prevent over heat problem.

●AC Driver

1. Available for all control interfaces, ex. RS 485, direct signal, PLC, HMI.

2. Convenient 220VAC driver power input from 60W. No more 24VDC power supply.

3. Built-in 24VDC mechanical brake control power.

4. Real motor speed display and signal output.

5. Panel control is always enabled with removed control or terminal control or RS485 control. Convenient for system set up or maintenance.

6. Excellent speed stability. Open loop and close loop speed control for selection.

7. With 0~5VDC, 0~10VDC and 4~20mA speed analog input.

8. Over current / heat / voltage, electric motor lock protection.

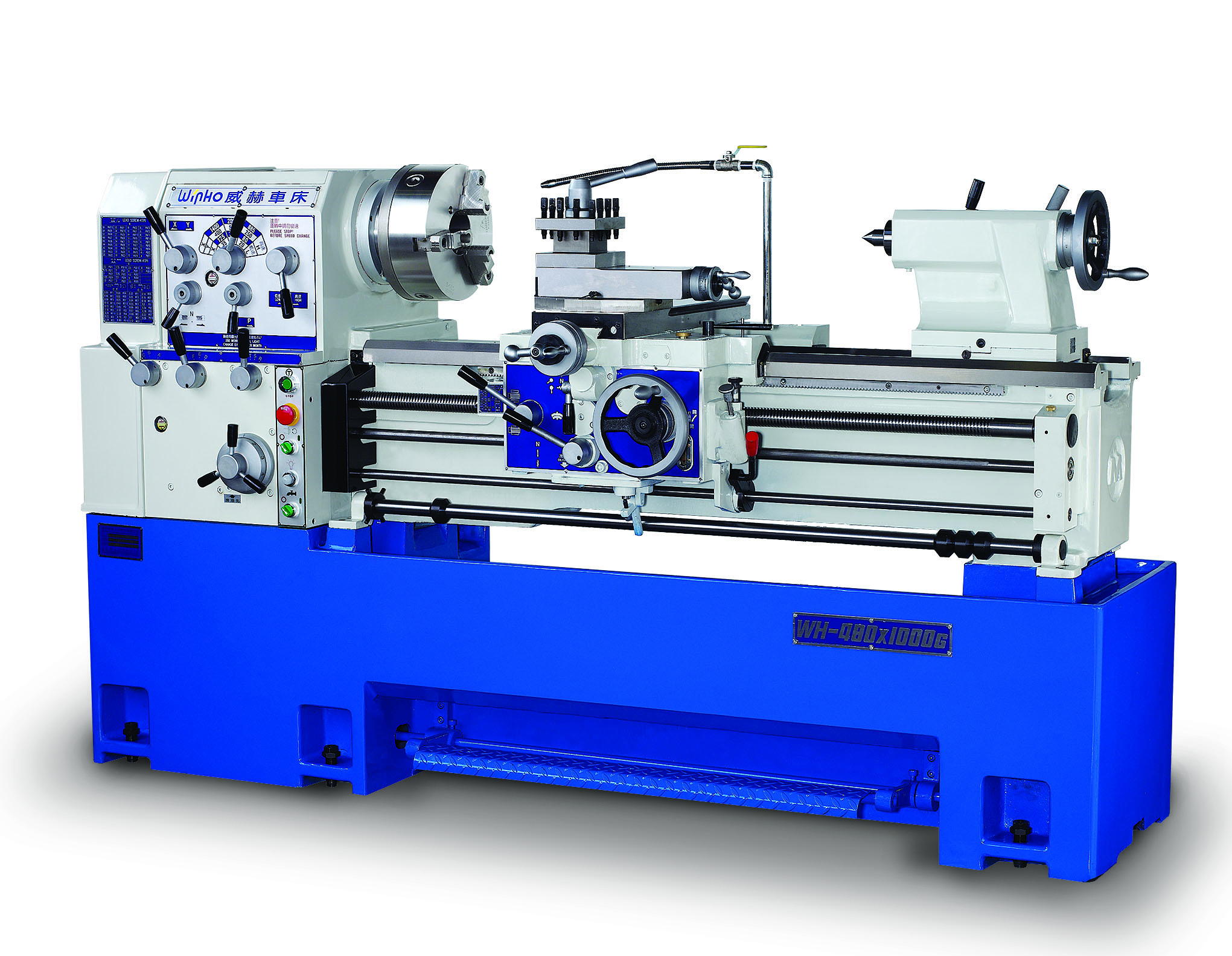

WIN HO TECHNOLOGY INDUSTRIAL CO., LTD.

Product Description :

High Speed Precision Lathe

1. Selective bed width:

S series: 300mm.

M series: 350mm.

L series: 400mm.

2. Varied spindle bore diameters:

S series: O58mm / O80mm (Option).

M series: O85mm / O105mm (Option).

L series: O85mm / O120mm (Option).

3. With FAG or SKF precision bearings installed on

spindle, maximum cutting depth can be 8mm on

50mm diameter and best roundness 0.003mm

(200mm long).

4. Equipped with plastic rear gears, shafts and

gears inside headstock are well protected if crash

should occur (S430 & S480 Series).

5. Thermal treated and precision ground alloy

gears.

6. Universal gearbox for both imperial and metric

thread-conversion table also attached.

7. Tracks of cross slide and bed are well lubricated

with lubrication pump (manual).

8. Overload device to ensure safety when

operating.

9. Wear-resistant phosphor bronze lead screw

nuts.

10. Durable reservoir oil bath type cross slide (for S

series).

11. Thermal treated Meehanite bed casting.

12. One-piece base for high rigidity and low

vibration.

13. High-capacity coolant tank offers sufficient

coolant output.

14. All series certified for CE.

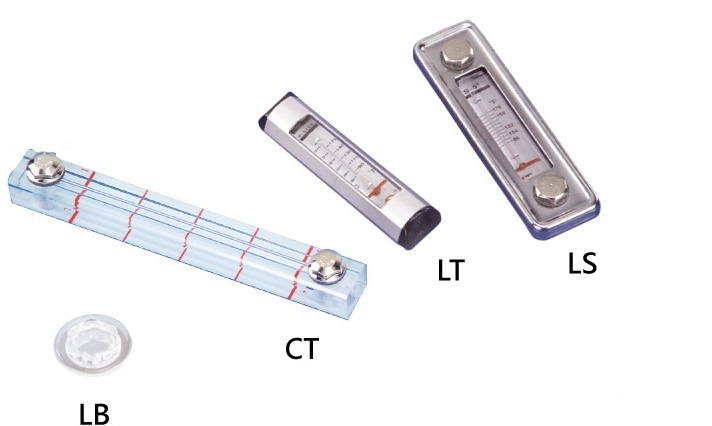

Reservoir Oil Bath Type Cross Slide