Theme

Digital Transformation

Green Transformation

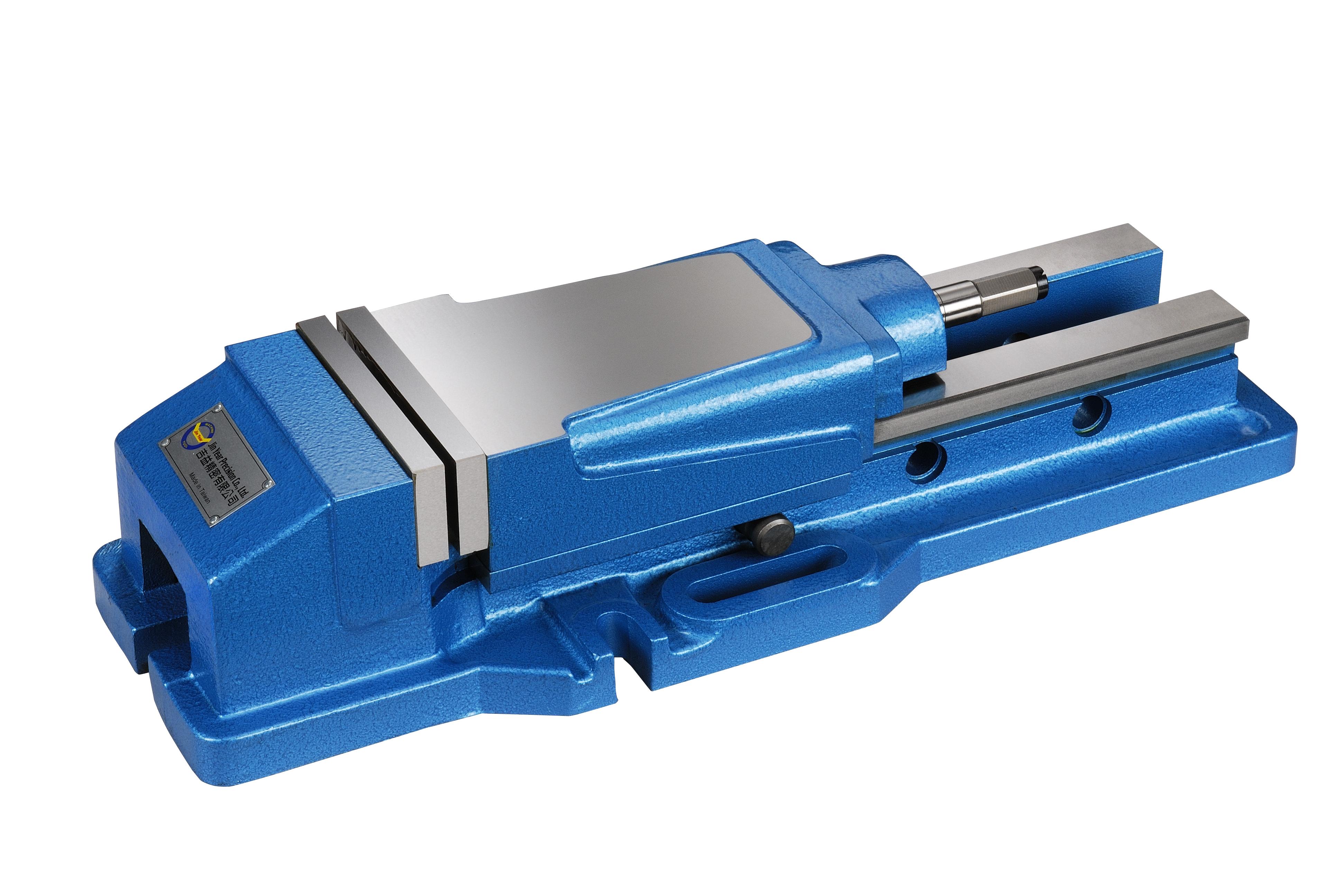

JIN YEAR PRECISION CO., LTD.

Product Description :

1.Most suitable for vertical machine center,milling machine.

2.Vise body is made of high quality ductile cast iron resists bending.

3.Pressure system for maximum clamping pressure with minimum force.

4.Three clamping ranges design:Quick to change and easy to operate.

5.Vise pressure system with one year guarantee.

HABOR PRECISION INC.

Product Description :

> Applications

Spindle, Linear Motor, Ball Screw, Grinding Liquid, CNC Cutting System, CNC Lathe, Other Machining Center

> Feature

Prevent deterioration of liquid.

Open coil type heat exchanger can prevent the obstruction problem of liquid circulating system.

Advance the speed of process.

Maintain the stability of dielectric fluid, advance the process quality.

Avoid fire risk cause by temperature rise and accumulating of dielectric fluid, advance the working safety.

Reduce the wastage of electrode.

Prevent the spreading of foul odor air, reduce the air pollution.

Easy operation and low noise.

Made of anticorrosive material.

KO-YAN PRECISE MACHINERY CO.,LTD

Product Description :

COMORK GJ-412 series CNC hybrid ID&OD grinding machine, longer length distance and bigger workpiece diameter included workhead B-axis function to do lathe spindle nose and milling spindle back pull bevel.

Also for deeper hole workpiece. Only need one step to finish multifaceted processing to save labor cost to increase efficiency and varied processing.

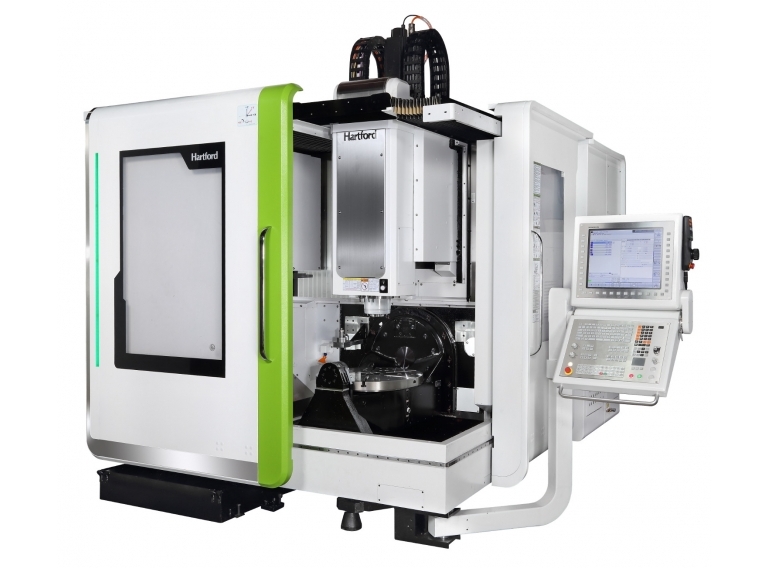

FAIR FRIEND ENTERPRISE CO., LTD.

Product Description :

★Gantry type structure

- Designed with a gantry type structure, the Feeler U800-5AX 5-axis machining center has the feature of spacious machining space, allowing large workpiece to be loaded and unloaded with ease. It is also convenient for operator to check the current machining condition at any time.

★U-shaped construction of base and column

-The advanced U-Shape structure significantly increases structural rigidity and machining accuracy.

-X.Y.Z axis rapid traverse rate reach 48m/min.

- Suitable for equipping with a large diameter of rotary table.

★Three axes overlap and separated from two rotary axes

- This design avoids a distance between the machining point and the intersection point of two rotating axes.

- Easy to compensate for the errors of radius on rotating axes and movement on three linear axes to ensure the machine's stability and accuracy.

★Separated design for three axes moving area and machining area

- This design feature not only makes chip removal more convenient, but also enables better chip-prevention capability of the machine.

- The rotaary shaft speed is increased by 800 rpm, which makes the turntable have a high-speed turning function.

CHING HSYANG MACHINERY INDUSTRY CO., LTD

Product Description :

1. Stable construction, strong rigidity, low vibration and high cutting

accuracy.

2. Floating feeding method makes aluminum extrusion or material with a

little curve feed easily.

3. Extraordinary horsepower design. Horsepower can be adjusted

according to the demand of saw blades. It cuts fast and has great

productivity.

4. Two saw blade lubricating devices for powerful spray cooling and auto

cooling via cooling liquid.

5. Electronic saw blade protection device and automatic saw blade

stopping device ensure operational safety and the smoothness of the

sawed faces.

6. Patent, After cutting, separating work piece before cutting tool moves

backward, machined surface will be shiny without tooling trace, the life

of saw blade is long.

7.Digit display allows for easy, accurate and fast length adjustment.

8. Applicable for sawing and cutting aluminum, aluminum alloy, brass

alloy, brass and plastic.

9. Control knob provides easy central control and operation.

10. Automatic material-absence sensing and stopping device.

11. Can be equipped with a sawdust collector for clean and convenient

sawdust collection.

12. Action as below:

Put into the material, automatic feeding, automatic positioning,

automatic cutting, can be cutting round, square shaped, head material

and tail material are automatically separated.

HYDROKOMP GmbH

Product Description :

Coupling elements of HYDROKOMP are made of stainless materials. This enables the elements to be used for all fluids and gases that are not aggressive. Special designs eg. for water steam or other media are available on request. HYDROKOMP offers coupling elements for two different operating modes depressurized coupling or pressurized coupling. The elements for depressurized coupling can be coupled pressurized up to 25 bar, if the specified volume flow is not be exceeded. When using higher operating pressure there ockures a risk of demaging the soft seal in the check valve as the result of high flow velocities of the fluid. This means for coupling of air up to 10 bar there should be always used the coupling elements for depressurized coupling. This also applies when the coupling process is initiated pressurized. The elements which can be coupled pressurized may be coupled up to the maximum specified operating pressure on one side and / or on both sides.

HYPERMAX MACHINERY CO., LTD.

Product Description :

JG3 makes customers to find the optimal process for the workpieces, owing to supplying high accuracy. This machine performs automatically grinding inner and outer diameters, faces and tapers. Simple 3 axes servo structure and twin wheel spindles provide various constitution to raise the broad range of workpieces.

TES ELECTRICAL ELECTRONIC CORP.

Product Description :

FEATURES

Automatic ferrous or non-ferrous substrate

material measurement

Non-magnetic coating on ferrous metal

substrate and insulating coating on

non-ferrous metal substrate measurement

Audible and visual warning when tolerance

limits are exceeded

Statistical display of significant values such as

mean value, standard deviation, min, max values

Units of measurement μm/mils select

LCD display with backlight

Auto power off