Theme

Digital Transformation

Green Transformation

TSYR TZUN INDUSTRIAL CO., LTD.

Product Description :

1.With circuit protection of breaking for motor, once any wire of three phases power source is broken off, this unit could cut off current to motor to prevent motor from being burn out.

2. Drill sleeves、tapping adaptors and borer holder are with rapid adaptors, very convenient for replacement of cutters.

3.Tapping adaptors with torsion control, tap bits are protected from being twisted off.

4.MTM-932ADL comes with drilling force control unit for Auto-feeding:

When drill bit is worn out, this unit will drive feeding intermittently or stop feeding.

Once feeding becomes difficult while making a hole, Please replace a new drill bit or re-sharpen the worn out one in order to protect both drilling tool and machine body from being damaged.

5. MTM-932ADL comes with three intermittent breaking rates for breaking chips :

Choose different feeding rates according to different drill bits and material to perform Auto-feeding operation.

This device can break chips intermittently and discharge them while Auto-feeding is processing, so that chips would not roll on drill bit. Easier to discharge chips.

6. MTM-932ADL comes with three feeding rates for Auto-feeding:

Feeding rates are separately 0, 0.15 and 0.25, please choose suitable rate according to size of drill bit and material of work-piece for drilling.

7. The rotation speed of the MTM-932ADL can be changed quickly during running.

It's very convenient for the operator, and the efficiency is increased accordingly.

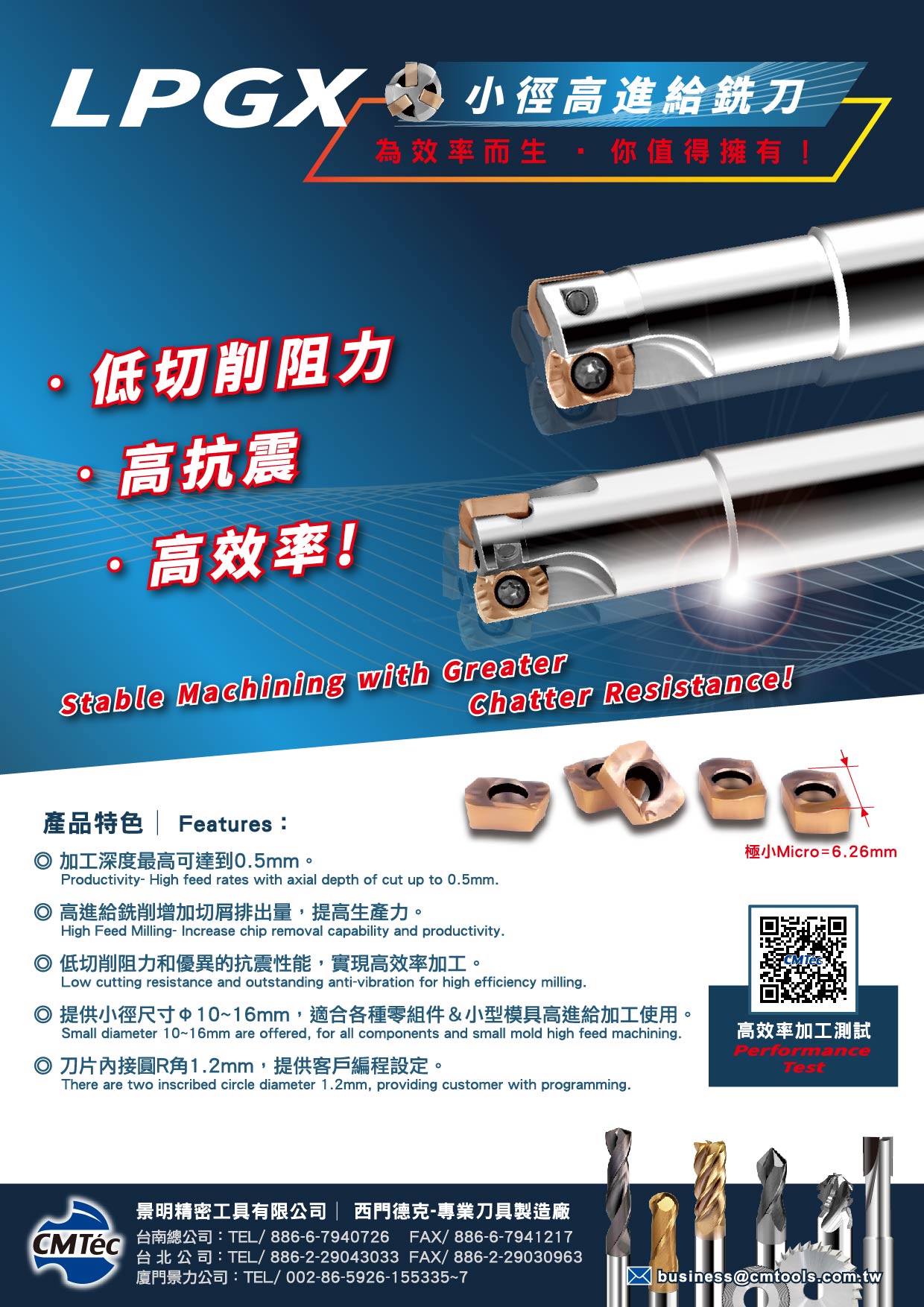

CHIN MING PRECISION TOOLS CO., LTD.

Product Description :

★ Productivity- High feed rates with axial depth of cut up to 0.5mm.

★ High Feed Milling- Increase chip removal capability and productivity.

★ Low cutting resistance and outstanding anti-vibration for high efficiency milling.

★ diameter 10~16mm are offered, for all components and small mold high feed machining.

★ There are two inscribed circle diameter 1.2mm, providing customer with programming.

JAINNHER MACHINE CO., LTD.

Product Description :

The aesthetic design of JHT-4010 will convince you, as well as the technology of the fast-moving hydrostatic guideway system.

The 3500rpm built-in spindle, the ability to carry a Ø510mm grinding wheel, and a wheel head axis capable of rotating ±30° for thread grinding are impressive features enabling you to move your manufacturing to a new level.

Jainnher's officially website:www.jainnher.com

Jainnher's Youtube:

https://www.youtube.com/user/GrindingMachineTech/videos

SGCAM TECHNOLOGY CO., LTD.

Product Description :

主功能介紹:<br />

全中文畫面,易學、易懂、易用,為加工業最適合的加工軟體,操作軟體完全不用背指令。<br />

可由AutoCAD製圖畫出工件外形,再匯入DXF、IGS圖檔,轉換為CNC程式碼。<br />

不必畫3D圖形,一條輪廓線和一條路徑線一般2D圖即可輕鬆轉出車銑的加工程式。<br />

快速C軸填充式的輸入方式 ,很簡單的方式就能轉出C軸加工程式。<br />

參數式的C軸工法操作條件更改G碼自動跟著改變。<br />

製作程式時車銑工法可依加工順序任意作排序調整。<br />

3D實體切削模擬預覽,可避免干涉及過切事件發生。<br />

主軸和副主軸的獨動或同動會自動等待(指定機型) 。<br />

同一個程式中可同時指定不同的切削計算方式有走刀式、走心式、櫛式。<br />

車銑的刀具庫參數可依實際機台型號的刀具位置做個別指定。<br />

可在端面、圓弧面、橢圓面上做刻字。<br />

支援單筆劃字型刻字。<br />

系統支援:<br />

支援廠牌有Citizen 、Star、Miyano、Tsugami、洽群、縉錩、利高、精機、瀧澤、程泰、寶麗金…<br />

支援側銑側鑽等循環加工指令G87、G88、G184<br />

支援極座標G12.1 、G13.1、 G112 、G113<br />

支援圓筒補間G07.1、G107

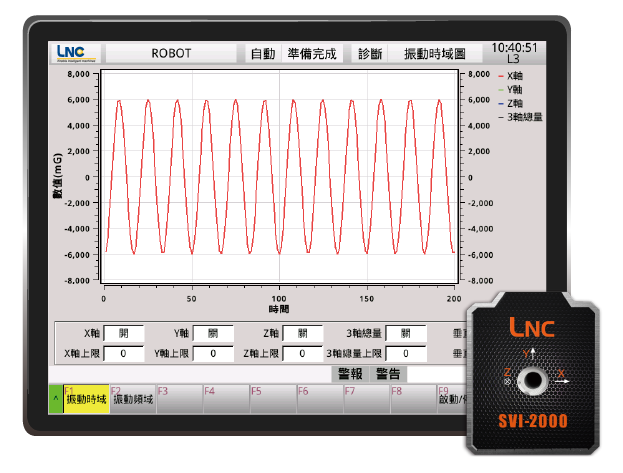

LNC TECHNOLOGY CO., LTD.

Product Description :

‧Low profile, high performance, easy installation, high applicability

‧High sensitivity, high precision

‧measurement:±16G, extremely low signal /noise ratio

‧XYZ three-axis vibration detection

‧Measuring frequency 3.32kHz(max.)

‧EtherCAT protocol

‧Water and oil proof, great anti-interference ability

‧Support time domain graph, frequency domain graph, abnormal vibration section marking of program function

‧Support smart function development: Broken tool detection, abnormal vibration detection, spindle protection, tool wear, adjustment assistance, equipment health inspection, etc.

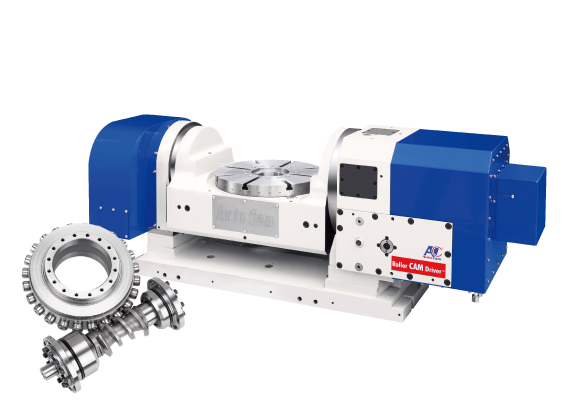

LEPAO ELECTRICITY MACHINERY CO., LTD.

Product Description :

* The Roller Adopt Rubber Material, Anti-Wear & Long

Lasting Use , Also Avoid Scratch On The Surface Of

Working Piece .

* Rolling By Hydraulic System, High Power & Equable, Highly

Rolling Quality.

* Available For Your Sample’s Length & Diameter.

* Available For Round Or Tapper Pipe.

* Adopt Hydraulic System, Can Operate By Manual Or

Automatic Way.

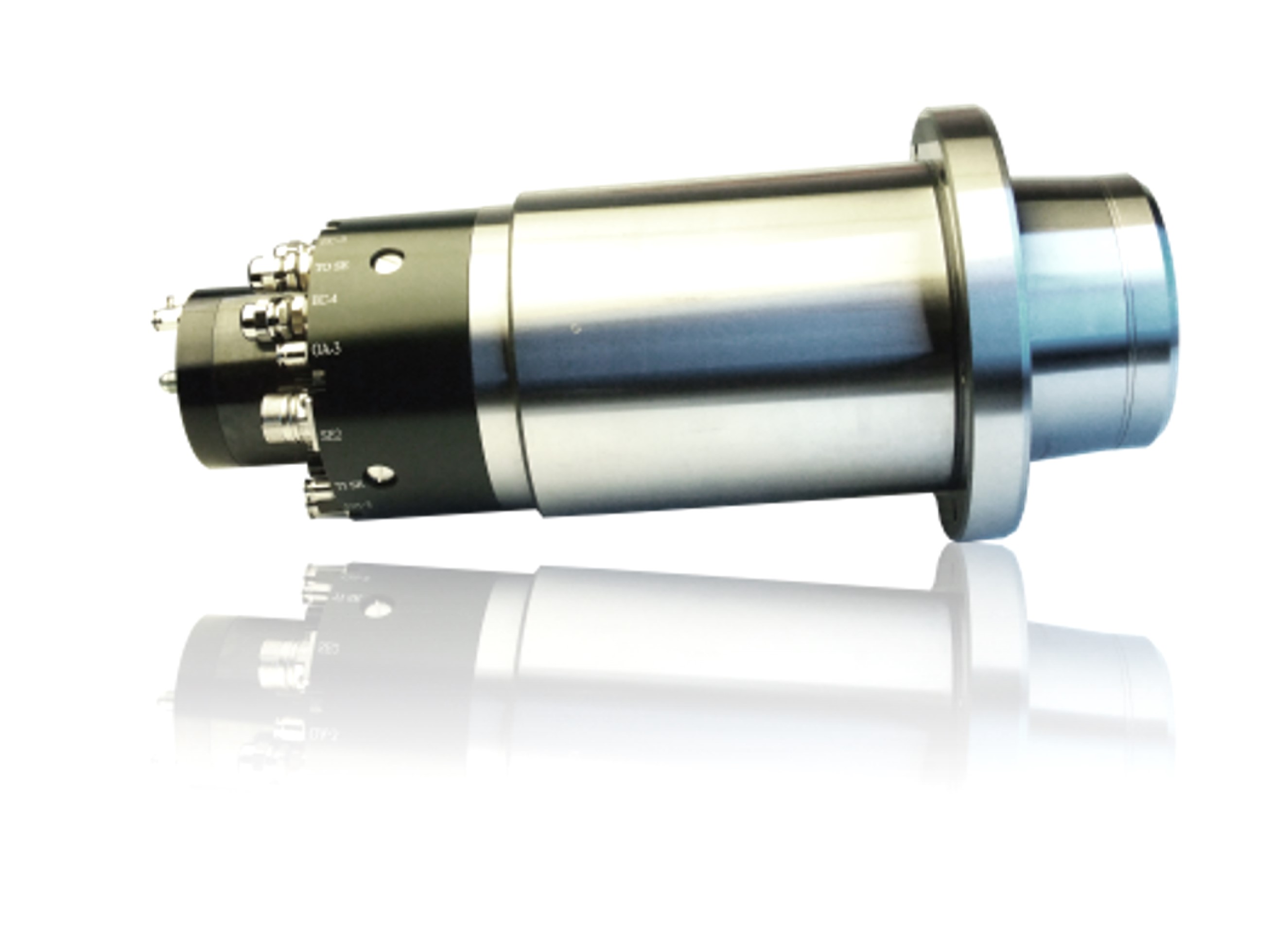

G-TECH INSTRUMENTS INC.

Product Description :

The performance of the spindle is an important key to processing quality. When you understand the performance of the spindle, you can predict and control the quality of the processed parts. The shape accuracy, roundness, and surface roughness of the workpieces are all related to the performance of the spindle. Only when the spindle is real measuring the accuracy of the spindle at the processing speed of the machine has meaning to the control of the quality of the processed parts, so measuring and understanding the performance of the machine tool, finding the best working speed, determining the warm-up time, even confirm the accuracy of the spindle after the collision.

LION provided this SEA analysis system as early as 1993 to help spindle manufacturers, machine tool factories and processing plants to reduce workpiece defect rate and improve product quality.

★The SEA system complies with the following international standards:

✓ ANSI / ASME B5.54-2005: "Methods for Performance Evaluation of CNC Machining Centers"

✓ ISO230: Test Code for Machine Tools, 3: "Determination of Thermal Effects" 7: "Geometric Accuracy of Axes of Rotation"

✓ ANSI / ASME B5.57-1998: "Methods for Performance Evaluation of CNC Turning Centers"

✓ ANSI / ASME B89.3.4: "Axes of Rotation, Methods for Specifying and Testing"