Theme

Digital Transformation

Green Transformation

EQP SERIES CO., LTD

Product Description :

Voltage Sensitivity: 10mV/(m/s²)±10%

Power Supply: DC15~36V

Constant Current: 0.5~10mA

Resonant Frequency: Approximately 40kHz

Frequency Response: 5~10kHz (±3dB)

Maximum Acceleration: 220m/s²

Shock Resistance: 49,000m/s²

Noise Level: Below 100μVRMS

Operating Temperature Range: -50~110℃

Detection Structure: Shear Type

Case Material: Titanium

Mass: Approximately 10g

INNOSERV FA INC. TAIWAN BRANCH (BVI)

Product Description :

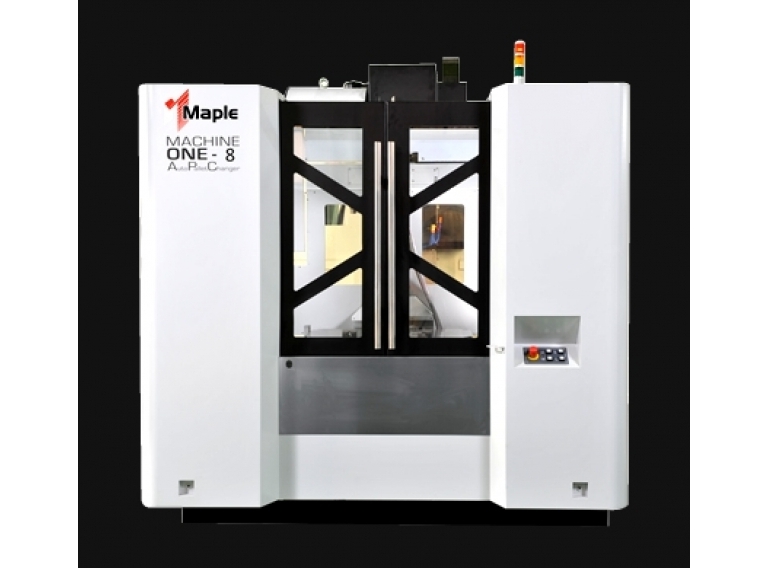

Micro Dynamics Vertical Machining Center Line opens a new era in multi-purpose and versatile machining centers. Compact, durable, powerful, strong and accurate, the MEGA/TERA Series starts a revolution in the market: the smallest C-frame machines provide powerful and precise results for manufacturers of dies and molds, aerospace, automotive, semi-conductor, job shops and general machine sectors.

The MEGA/TERA Series has been designed with the latest in technology being utilized throughout the machine with productivity in mind. From its EtherNet/IP architecture for easy automation and integration into systems and cells, to its Motion Control for fast and smooth operations used in all industries, the MEGA/TERA Series has quickly become one of the industries leading machine tool lines of Vertical Machining Centers.

The MEGA/TERA Series has been refined through years of research and development of new technologies that greatly enhance the machines for the rigors of the Mold and Die industry.

All series are equipped with

■ 15,000 rpm Built-In Spindle

■ Thermal Compensation (DYPEC)

■ Micro Dynamics HMI

FALCON MACHINE TOOLS CO., LTD.

Product Description :

Improved grinding performance, precision and stability

Chevalier's FSG-20/24ADIV Series of surface grinders now includes four new machine sizes, along with several newly designed features: a traveling column structure to further reduce vibration and achieve higher accuracy; a spindle that can withstand heavy load grinding; and a double-V guideway for smooth, stable longitudinal movements. Fully supported worktable design. Maximum table speed: 30 m/min (98.4 fpm), increases processing efficiency. Integrated machine-body temperature control system greatly improves accuracy and stability.

These four larger sizes, along with the entire FSG-20/24ADIV Series, offer several design features to shorten processing and non-processing preparation while delivering high-precision workpieces: iSurface control, variable speed spindle, constant surface speed, smart grinding path and in-machine manual dynamic balancing.

The driving forces behind this series pave the way to smart manufacturing by meeting the current grinding demands and standards required by the automotive, electric vehicle, mining, aerospace and job shop industries.

FUTECH PRECISION CO.,LTD.

Product Description :

Ultra-short, large-diameter rotary hydraulic cylinder, lightweight design, more stable performance during high rotation, reducing spindle load.

The built-in safety self-locking valve ensures the pressure is immediately maintained during abnormal power outage and the built-in pressure relief valve.

Dual-purpose type, can be installed by the front and rear ends.

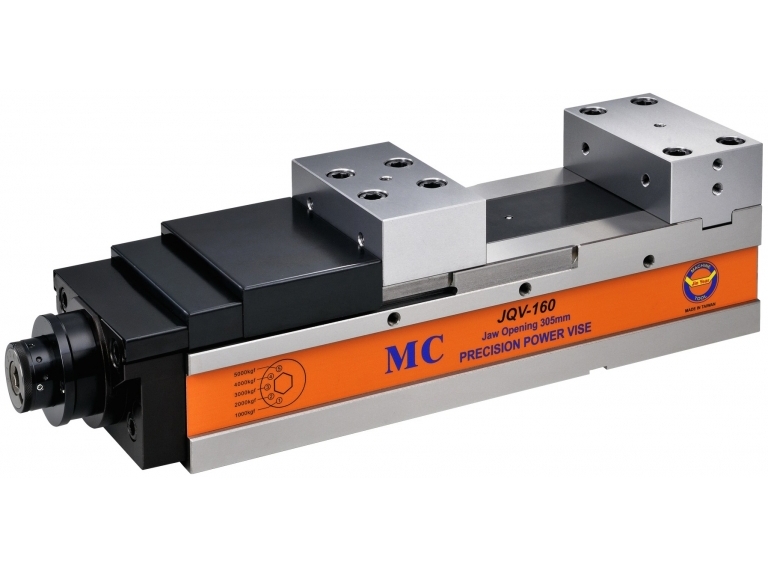

JIN YEAR PRECISION CO., LTD.

Product Description :

Features:

1.Pressure Constant. Clamping force can presetting, repeat use the same clamping force.

2.Vise body is made of ductile iron FCD-60.

3.Vise bed hardened to HRC45° and maintain accuracy for long.

4.Vise body height-size and the guide block side are all made with full control, can 2、3 or 4 vises to perform a job at a time.

5.The length of vise body is very short, but the clamping range is very big. It works with every kind of milling machine, CNC machine center.....

SING CHIUN ENTERPRISE CO.,LTD.

Product Description :

Product categories include:

(1) UL WATERPROOF NYLON POWER

DISTRIBUTION HOSE

(2) STAINLESS WIRE BRADING CORRUGATED

NYLON TUBES

(3) NYLON TUBE QUICK CONNECTOR( Plastic steel )

(4) MS-PLUG/CONNECTORS ADAPTER( Plastic steel )

(5) NYLON TUBE COMPRESSION JOINT

(6) UL NYLON TUBE QUICK CONNECTORS ( Plastic

steel )

(7) UL MS-PLUG/CONNECTORS ADAPTER ( Plastic

steel )

(8) 2 1/2" NYLON TUBE CONNECTOR ( Plastic steel )

(9) NYLON TUBE QUICK CONNECTOR ( Simple type -

no waterproof )

HAINBUCH GmbH

Product Description :

HAINBUCH segmented mandrels use state-of-the-art clamping technology that is convincing, even in the most critical applications. The central element is the vulcanized segmented clamping bushing. Because conventional clamping bushings are made of spring steel and are only annealed to spring hardness, they are »soft« and they must »bend« to clamp the workpiece. HAINBUCH segmented bushings are made of case-hardened chromium-nickel-steel and have segments that are extremely hard and rigid. All contact surfaces are completely ground in one operation guaranteeing optimum concentricity.

Mandrels with hexagonal clamping geometry, the MAXXOS mandrels. are the optimized version for round MANDO mandrels. Thanks to the hexagonal geometry, a previously unattained clamping force and rigidity with the best precision is now achieved for internal clamping. The robust and powerful clamping mandrel delivers first-class values in terms of dirt density. The force is transmitted by positive locking, in addition to optimum process reliability and long maintenance intervals.