Theme

Digital Transformation

Green Transformation

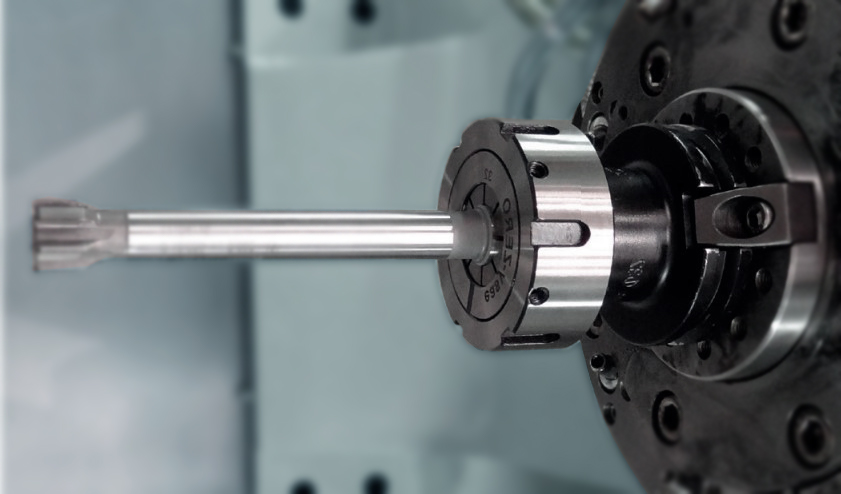

PRAISE PRECISION IND. CO., LTD.

Product Description :

NEW PRODUCT- CUTTING KNURLING TOOLS USED ON LATHE

Method of forming knurling

1. Press forming(Form knurling)

Press knurling tool directly to workpiece in turning on the lathe

to form the patterns. Pressure is applied to the lathe spindle, and the outside diameter of workpiece will become bigger

2. Cutting forming(Cut knurling)

The knurling tool is applied to workpiece just like cutting, less pressure

to lathe spindle and less machining resistance, forming a clear patterns, the best choice for using on CNC lathes

HO CHEN MACHINERY & ELECTRIC IND. CO., LTD.

Product Description :

XYZ axes travel: 500x400x185mm (20"x16"x7") inch

U axis travel: 300mm (12") inch

Z axis single travel: 400 mm (16") inch

Work table: 800x450 mm (31"x18") inch

Max. Workpiece: 1250x650x390 mm (49"x26"x15") inch

Max. Workpiece weight: 1400 kg

Max. Electrode weight: 185 kg

Machine net weight: 2100 kg

Oil level: 110-360 mm (4"-14") inch

Packing Size(LxWxH):2340x2320x2500 mm (92"x91"x98") inch

Work Table to platen:

1. Z axis single travel: 230-630 mm (9"x25") inch

2. UZ axis: 230-715 mm (9"x28") inch

Filter: 1

Paper filter:2

Capacity:550 Liters

Machine Features

> Windows CE controller

> A dialog window with picture description.

> Special repaired frames to quicken the maintenance speed.

> Close-loop design of digital feedback on three axes of the machine significantly increases positioning precision and ORBIT-CUT machining accuracy and efficiency.

> Simple operation interface.

> Common function keys are located on the operational panel for direct use.

> Hot key setting.

> ATC (automatic tool change) and C-axis 360° index can be installed; the process of coarse machining to ultra-fine machining can be completed at one time.

> Dialogue diagram provides various hole-expanding modes such as quick search of edge, centers and datum marks.

> Rich color graphic (the same resolution as a PC screen).

> Automatic multi-step machining (coarse, medium coarse, medium fine, fine, superfine)—up to 10 steps.

> Unlimited number of machining conditions can be saved as machining archives. Each set of machining conditions can be edited, modified or stored. They are easy to edit and easy to find.

> Automatic origin search and multi-point coordinate memory capability.

> 1/2 design capability, ARC automatic discharge waveform detection and automatic adjustment.

> Automatic center position detection, automatic compensation, search of hole center and deepest point; fixed hole machining (cyclic mode, independent mode), which is suitable for different machining conditions; Radial, circular, square, linear (vector), coning, 45° hole-expanding machining.

> Three-axis beeline, two-axis arc, three-axis helix.

> Chinese/English versions interface, metric/British system switch and Z-axis quick up, quick down, slow up and slow down capability.

> Lateral machining, three axes, six directions (plane rotation).

> All alarms describe the source, date and exact time of problem occurrence.

> Optical scale is applied for close-loop position control, enabling extreme position for machining.

> Automatic editing—settings can be done according to type of material, work piece size, machining depth, one side die clearance, final current and rate of electrode wear.

> CNC models possess conventional capability of consistent level of energy discharge, achieving stable and rapid machining and smooth high quality on machining surface while the rate of electrode wear is still low.

> Monitor page indicates machining path and orbital pattern in use.

YI CHANG MACHINERY CO., LTD.

Product Description :

This model is a Customized Machine that integrates a cam indexer. It connects a drilling machine and a tapping machine, achieving a one-time completion of drilling and tapping.

The machine's uniqueness lies in its advanced pneumatic clamping automatic feeding system, allowing operators to easily complete tasks and reducing operational burden.

Not only does this enhance work efficiency, but it also makes work precision easier to control.

In the pursuit of efficiency in modern manufacturing, our machine ensures operational simplicity, allowing you to focus more on the precise adjustments of your workpieces.

This video demonstrates how it achieves a one-time completion of drilling and tapping, providing higher work precision.

If you have any thoughts or inquiries about our machine, please leave a comment below or call our company. We look forward to engaging and communicating with you!

PALMARY MACHINERY CO., LTD.

Product Description :

Super rigid structure, stable without deformation. The double support bearing type spindles offer even grinding force on the contact surface. During grinding process, the stress is even on both ends of spindle to avoid taper shaped workpieces. Computer numerical control from 1 ~ 6 axes satisfy requests for customized specification. Fitted with wider wheel, suitable for efficient mass production.

Ametek Taiwan Corp., Ltd.

Product Description :

PGI NOVUS: Fully automatic, ultra-high precision measuring system for surface finish, contour, 3D and diameter.

FTS LASER:Surface finish and contour instrument of high precision & large range.

i-Series PRO:High resolution surface finish and contour instrument for precision machining.

Intra & Surtronic Roughness:High precision surface finish and contour instrument for workshop and quality inspection room measuring & Super durable portable roughness testers.

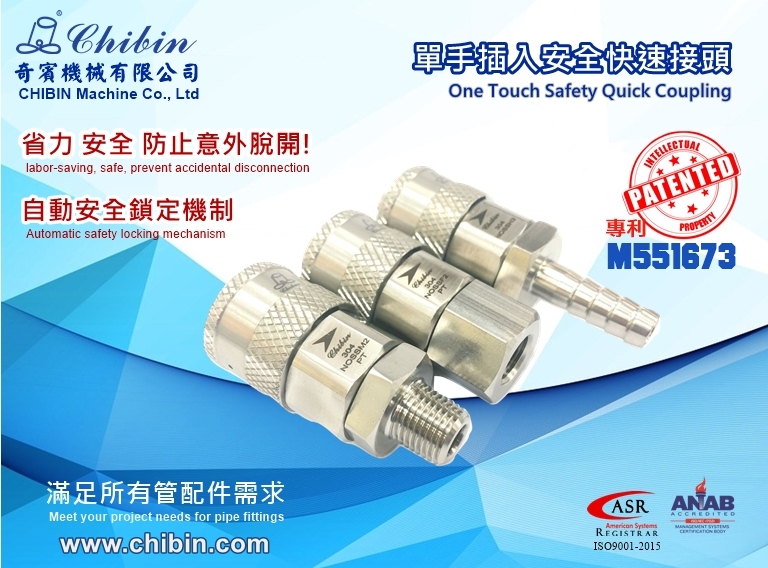

MONGTEC PRECISION INC.

Product Description :

Product Features

◎ Correction of runout errors and misalignment

◎ For metallic sealed and normal collets as per DIN 6499 / ISO 15488

Product Advantages

◎ Easy to set

◎ Maximum process capability due to correction of runout

◎ Extended tool life due to perfect runout

◎ Highest quality of bores due to correction of runout

GP MACHINERY CO., LTD.

Product Description :

AREA OF USE:

Processing structural components for trains and the air and space travel industries

Construction of models and prototypes

Design

RAW MATERIALS AND PROCESSING:

Finishing steel and cast iron

Roughing aluminium, Zamac, CFRP/GFRP

Artificial materials, wood and ureol

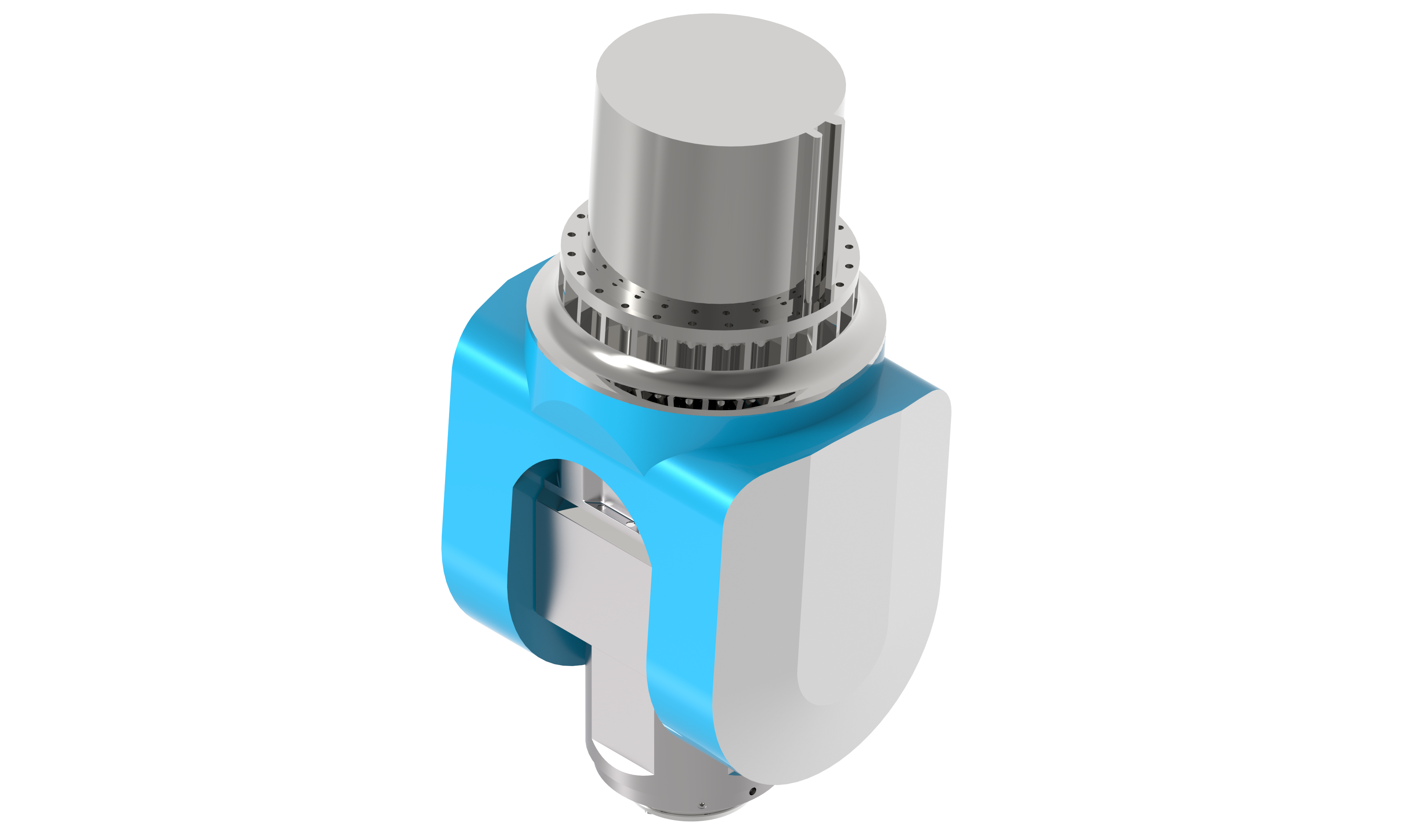

BUFFALO MACHINERY CO., LTD.

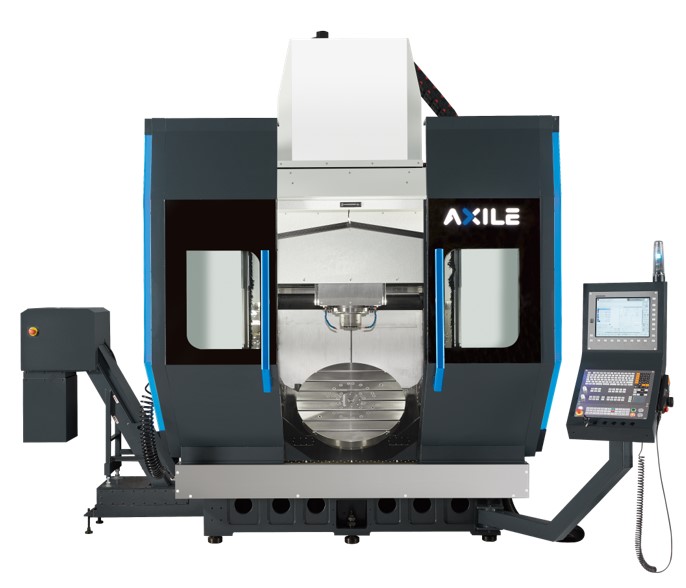

Product Description :

The AXILE G8’s powerful gantry design perfectly balances rigidity and precision, ideal for the machining of complex workpieces.

With a maximum loading capacity up to 1,300 kg on a swiveling, rotary table, complemented by high-performance built-in spindles, the G8's agility enables production of a wide range of large parts and tools.

The G8 MT option offers both milling and turning in one machine, greatly increasing operational flexibility. By reducing set-up times and potential clamping errors, the G8 MT can efficiently machine a wider variety of parts, including cylindrical components.

WEXTEN PRECISE INDUSTRIES CO., LTD.

Product Description :

■ Maintained the constant oil temperature in order to prevent process-ing precision-losing.

■ Kept oil viscosity and avoid oil deterioration to stable spindle working.

■ With the temperature control panel to avoid thermal expansion.

■ Built-in failure-detection system that connects to control panel in order to warn users and prevent further damage to machine.

■ Filling high-efficiency environmental refrigerant, without pollution.