Theme

Digital Transformation

Green Transformation

KAO FONG MACHINERY CO., LTD.

Product Description :

5-axis synchronous machining of the KMU series can be used for multi-faceted processing of workpiece clamping positioning at one time or processing deep hole mold and inverted hook area.

Three-axis structure using box-type construction design, which can effectively improve the rigidity of the machine.

X / Y / Z axis with high rigidity roller type linear guideway, with high rigidity, fast moving, low wear and other characteristics, which can greatly enhance the processing dynamic precision and stability and effectively increase production efficiency.

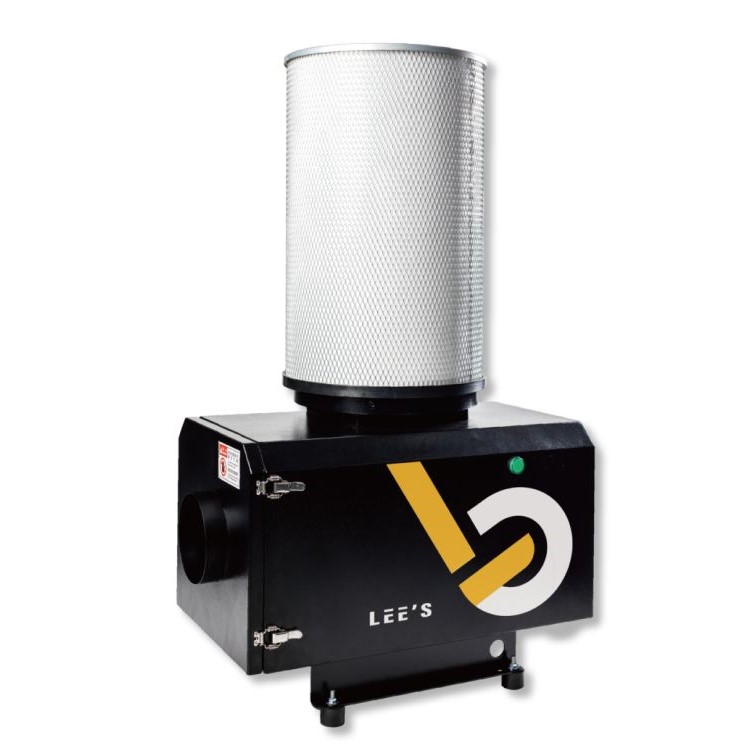

LNS TAIWAN CO., LTD.

Product Description :

FEDEK FOX HM oil mist collectors provide the perfect solution for the collection of soluble coolant and oil mist. Specifically developed for the elimination of mist and wet machining operations.

LNS oil mist collectors will not only efficiently improve the working efficiency, optimize the productivity, but create a safety working environment for employees. Besides, bring the benefit of environment friendly.

●1st STAGE - PREFILTER: Made up by one or two cleanable metallic filters, this filter blocks bigger particles, and extend the filter lifetime. 2nd STAGE - CENTRIFUGAL FILTRATION: A special impeller ensures the centrifugal effect that enables the continuous evacuation of collected particles. 3rd STAGE - MAIN CARTRIDGE FILTER (with standard filter): Made up of different layers of media, the final stage provides an efficiency up to ISO ePM1 85% according to the ISO 16890 norm.

●The filtration efficiency of the OIL MIST COLLECTOR determines how clean the air is inside the workshop and how healthy is the environment for the operator. In addition, trained LNS technicians can provide onsite measurement of air quality to measure with high accuracy how clean the air is. The analysis is conducted using a sophisticated dedicated instrument.

●Best in efficiency - air flow regulating valve allow optimal filter lifetime. HM series are all equipped with air flow regulating valve which meets your requirements without install external ones.

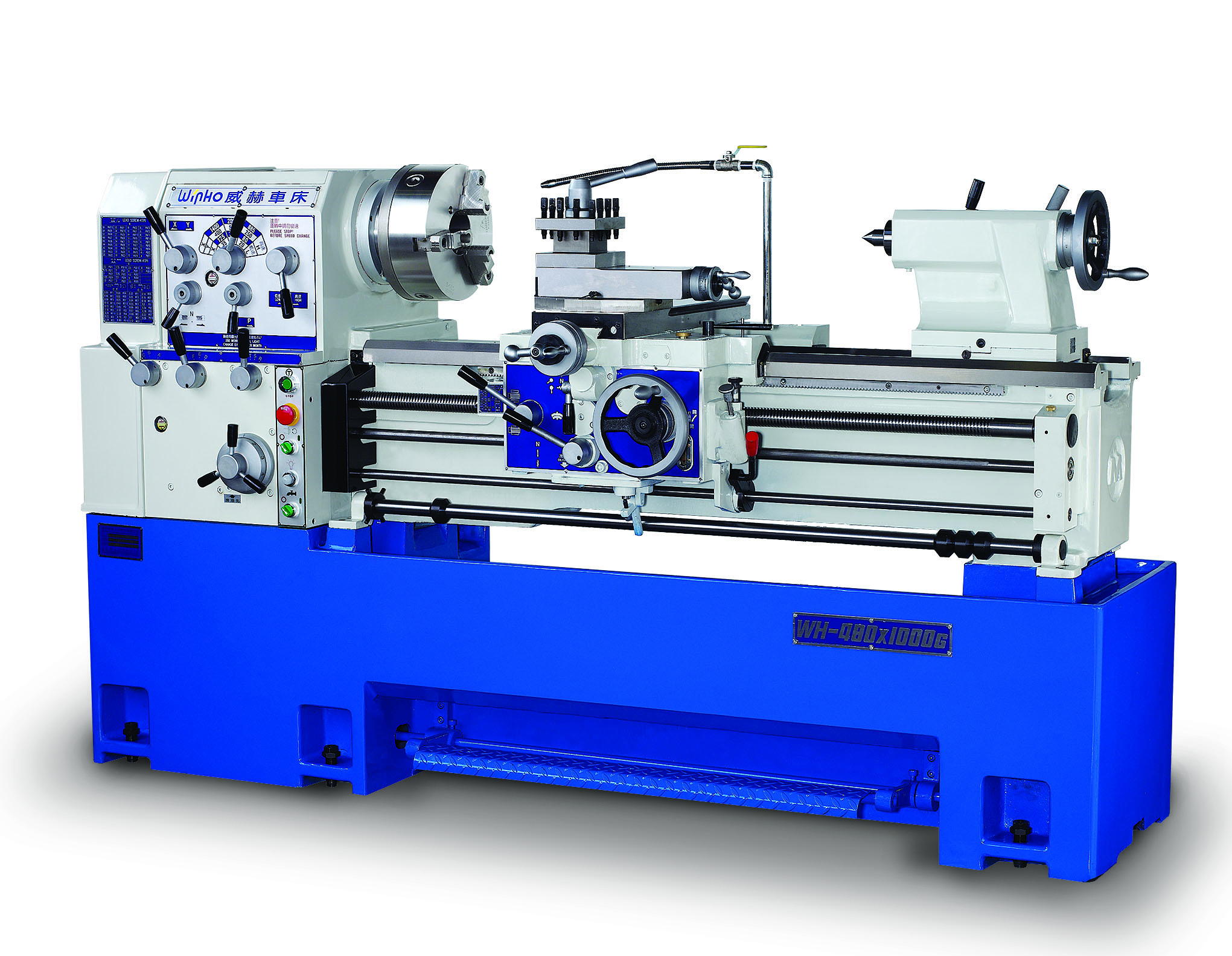

WIN HO TECHNOLOGY INDUSTRIAL CO., LTD.

Product Description :

High Speed Precision Lathe

1. Selective bed width:

S series: 300mm.

M series: 350mm.

L series: 400mm.

2. Varied spindle bore diameters:

S series: O58mm / O80mm (Option).

M series: O85mm / O105mm (Option).

L series: O85mm / O120mm (Option).

3. With FAG or SKF precision bearings installed on

spindle, maximum cutting depth can be 8mm on

50mm diameter and best roundness 0.003mm

(200mm long).

4. Equipped with plastic rear gears, shafts and

gears inside headstock are well protected if crash

should occur (S430 & S480 Series).

5. Thermal treated and precision ground alloy

gears.

6. Universal gearbox for both imperial and metric

thread-conversion table also attached.

7. Tracks of cross slide and bed are well lubricated

with lubrication pump (manual).

8. Overload device to ensure safety when

operating.

9. Wear-resistant phosphor bronze lead screw

nuts.

10. Durable reservoir oil bath type cross slide (for S

series).

11. Thermal treated Meehanite bed casting.

12. One-piece base for high rigidity and low

vibration.

13. High-capacity coolant tank offers sufficient

coolant output.

14. All series certified for CE.

Reservoir Oil Bath Type Cross Slide

TOP POWER MACHINERY ENTERPRISE CO.

Product Description :

We exclusive patented technology and is committed to developing and producing products that meet global environmental protection goals. The machine is made of all metal and stainless steel materials. From the perspective of environmentally friendly equipment, it realizes the concept of net-zero and low consumables. Using the principle of physical centrifugation, a unique oil throwing device is designed, which can effectively extend the maintenance cycle and increase the filtration rate of oil smoke generated by the processing machine to more than 85%. In addition, the new generation design improves the performance of the machine with the same horsepower by 50%. Under the same efficiency, the power saving rate can be as high as 200% to 400%.

TORNG INDUSTRIAL CO., LTD.

Product Description :

* To provide cooling, lubrication and chips removal functions simultaneously.

* It's designed for machinability, machining speed and extend the tool life.

* To save machining time and reduce machining cost.

* To ensure high quality of machining and cutting performance.

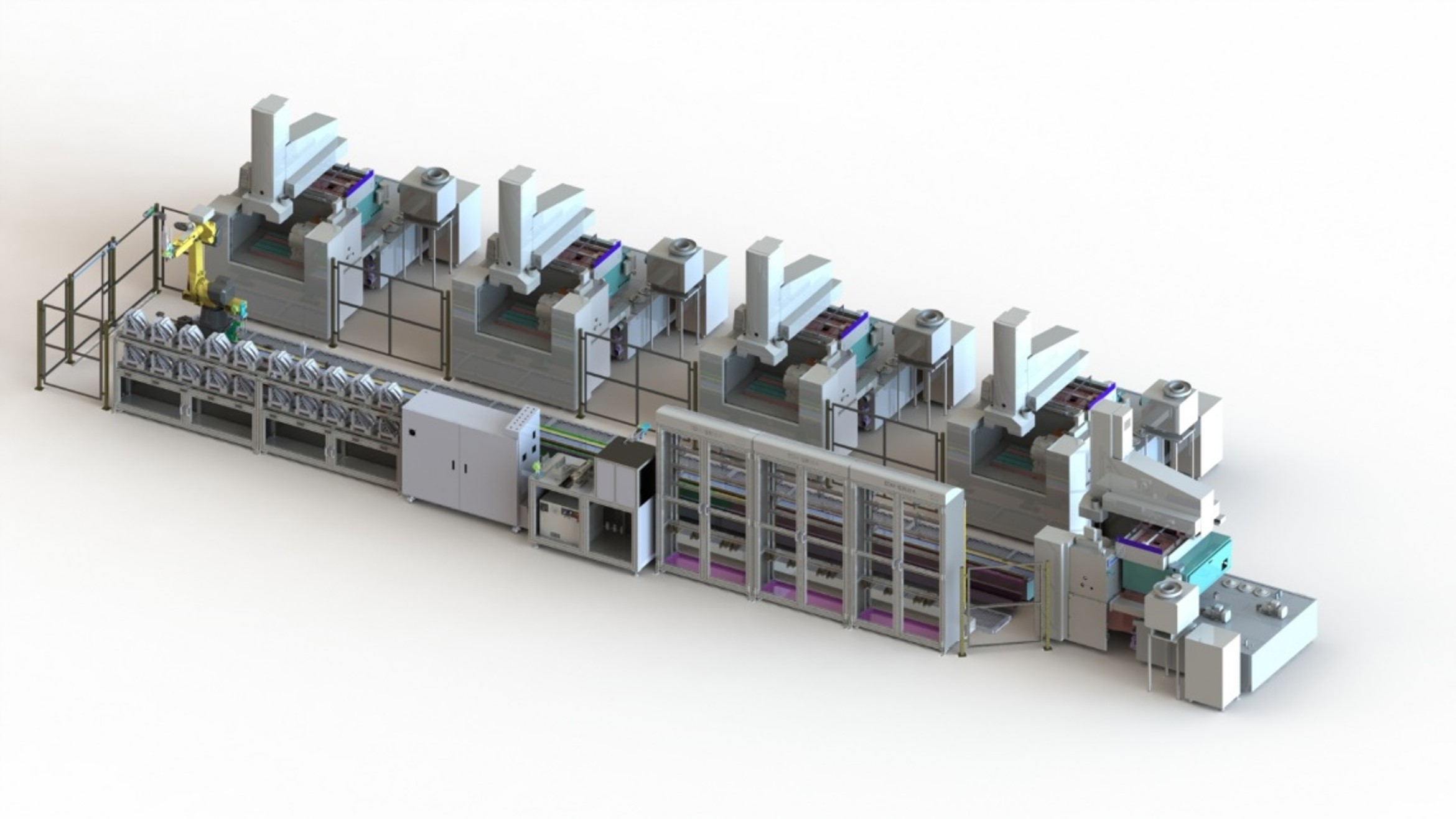

OSCAR E.D.M. COMPANY LTD.

Product Description :

Quick Integration

EX/EXD Series electrical discharge

machine, capable of easy integrated with

MES system, online measurement,

storage system and etc via OPCUA, API.

Smart Production line

Actual application on automobile moulding industry in

Europe. EX series sinker EDM integrated with MES and

milling machine where perform the production just-intime

without any interruption. By increasing 30% of

overall equipment effectivenss (OEE), 2 EDM will then

bring out extra 3,000 hours working time per year

YOKE INDUSTRIAL CORP

Product Description :

1. Size from M8 to M90 to fulfill your demand

(M8 ※ 0.3t _ M90 ※ 40t)

2. Design Factor 4:1, Working load limit could be up to 40 tons

3. Lifting point is made by forged alloy steel, quenched and tempered

4. Suitable for all loads which swivel and tilt especially for heavy duty, material handling, mold & die industries.

5. Ball bearing inside is easier for flipping working piece and rotation.

6. Light weight, High Performance, easily for using

7. Deliver with test certification to guarantee your safety