Theme

Digital Transformation

Green Transformation

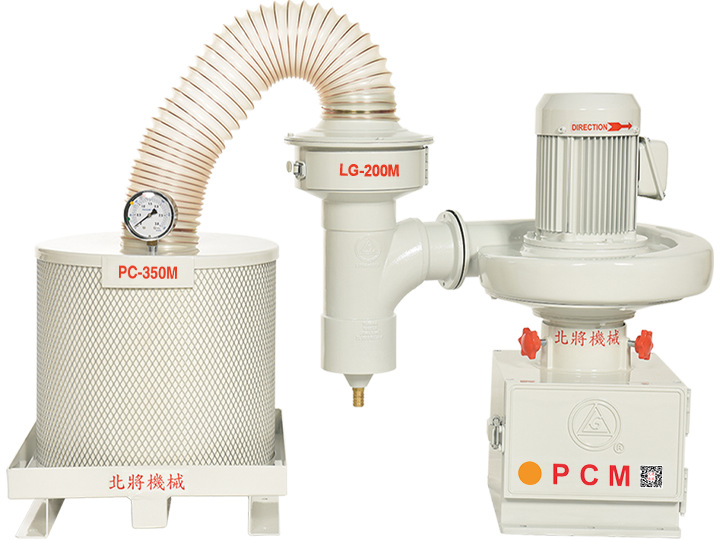

PEI CHIANG MACHINERY CO., LTD.

Product Description :

北將機械公司專業處理油霧油煙、油氣已有20年經驗,新推出M系列油霧回收機及分離式油煙處理座,擁有專利設計,可直接安裝,多功能彈性化組合,能因應不同的生產環境需求。

TAIWAN 3AXLE TECHNOLOGY CO., LTD

Product Description :

Feature of product :

The light spot can be adjusted from 0 to 300mm;

Rust removal gun weight 0.7KG

The system monitors the running status from time to time, monitors and collects the running status of lasers, chillers, and control panels;

Light weight, small size, ergonomic design, comfortable grip;

The safety lock touches the light;

The operation is simple and easy to use, and the requirements for operators are extremely low;

Strong anti-interference;

The fully sealed structure has built-in water and air channels;

Safe and pollution-free, low maintenance cost;

The hand-held laser rust removal and cleaning machine adopts the latest generation of optical fiber laser, which has the advantages of simple operation, small appearance and fast cleaning speed. It has an irreplaceable cleaning process in hardware material rust removal and oil removal. Easy to install, control and automate. Simple to operate, turn on the power and turn on the equipment, you can clean without chemical reagents, media, dust and water, you can manually adjust the focus, clean with curved surfaces, and clean the surface with high cleanliness Advantages, can remove resin, oil, stain, dirt, rust, coating, plating, paint on the surface of the object.

SPINDLEX TECHNOLOGIES CO., LTD.

Product Description :

Spindle housing diameter : 120mm

Tool interface : Quill D22/38 M22XP2.0

Maximum speed : 42,000 RPM

Lubrication : Oil-Air

Motor power : 11.5/17 Kw

TOP POWER MACHINERY ENTERPRISE CO.

Product Description :

The latest crumb collection and +1um precision filtration machine. This bottom debris recovery filter is equipped with a 1.5-inch large suction pump, which can quickly collect and dry the bottom debris and sediment in the water tank, allowing customers to clean it conveniently. This machine is equipped with a multi-functional stainless steel filter barrel that can collect coarse bottom debris. At the same time, using our patented technology, there is no need to replace the filter barrel, and it can continuously perform precision filtration up to 1um, thereby intercepting and filtering impurities and suspended particles in the water.

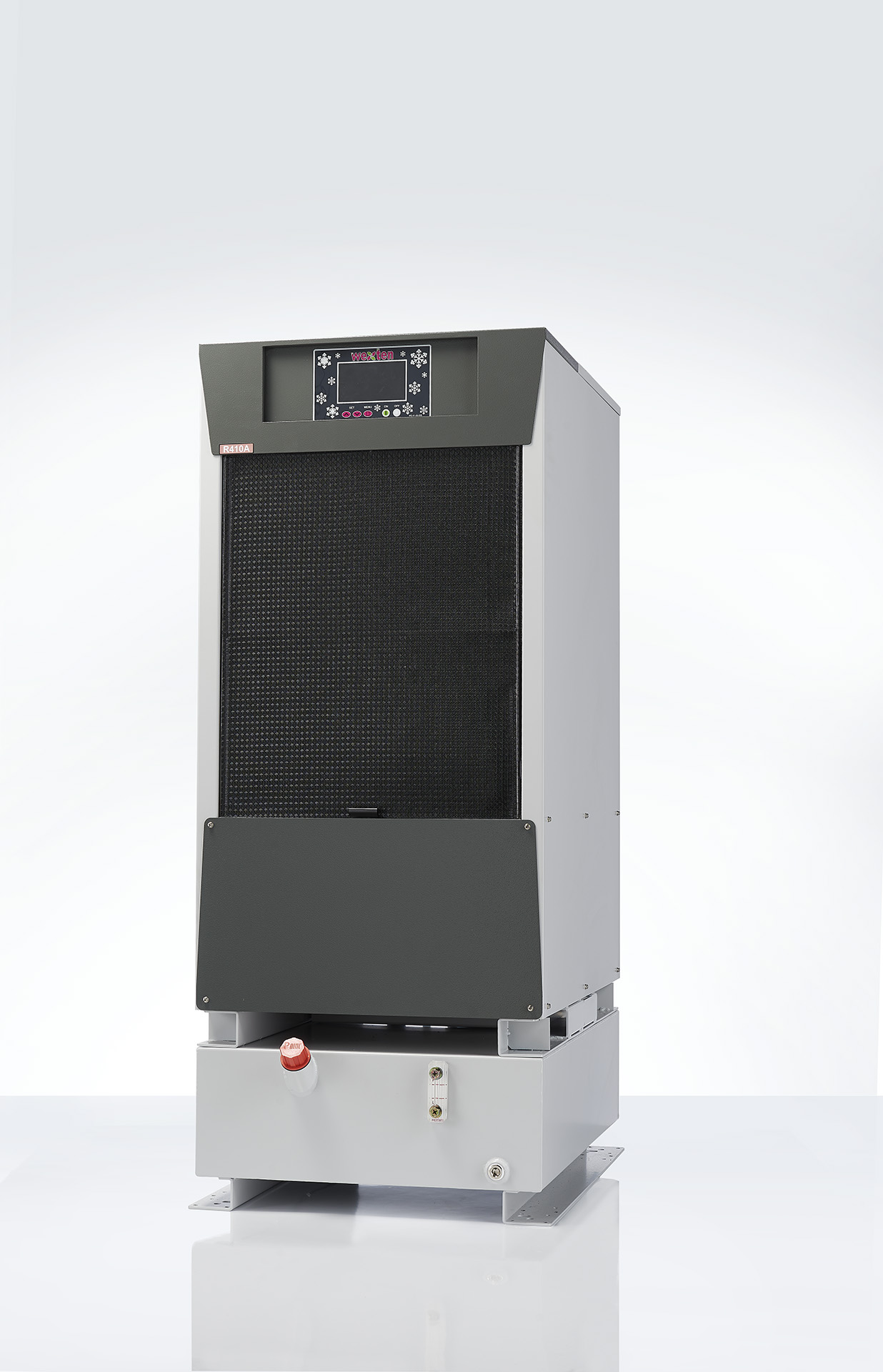

WEXTEN PRECISE INDUSTRIES CO., LTD.

Product Description :

■ Full series of inverter compressors are smooth start. There is no-start instantaneous high current and saving power more than 33%.

■ Unique design of multi-function LCD panel and it's provides -0.10°C temperature control stabilization.

■ There are 15 malfunction protection to ensure normal operation of cooler.

■ When low heating load is happend,the cooler will operate in low load mode and combined accurate temperature control and energy saving.

■ Groove recessed panel design is reducing oil mist infiltration into electrical control unit.

■ Using high-efficiency heat exchanger to enhance cooling efficiency.

■ Using high-efficiency environmental refrigerant and without pollution.

■ Up-to 95% materials of machine are recyclable and eco-friendly.

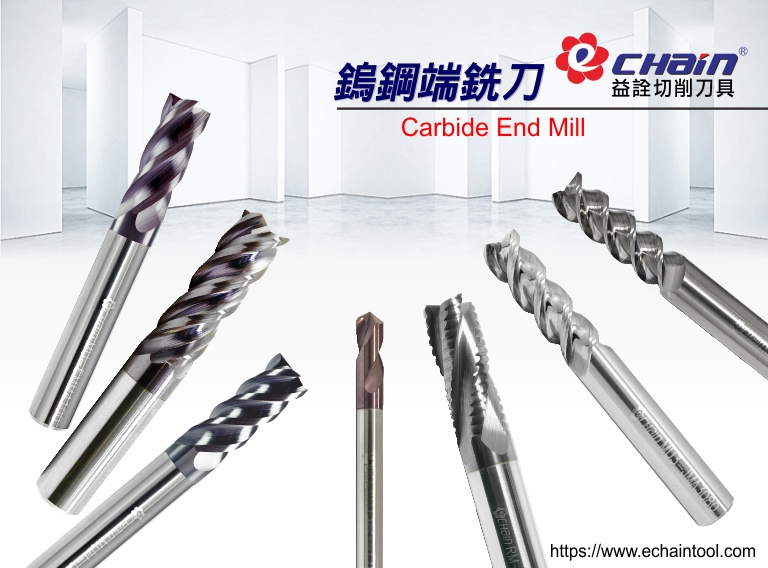

ECHAINTOOL PRECISION CO., LTD.

Product Description :

"Recently, in response to market demand, we have developed a number of new carbide end mills, starting with the "" Unequal split and Unequal spiral Carbide end mills"" (MUH-IMM Series) and "" Unequal split of Carbide end mills "" ( MUH-GMM series).

The two carbide end mills can enhance the vibration generated by the processing and increase the smoothness of the machined surface through the division ratio of the cutting edge. The unequal spiral design of the MUH-IMM series can strengthen the tool during high-speed machining. Anti-cracking; both carbide end mills have a special round groove design, which can effectively control the chip removal frequency during the plunge milling process.

In order to meet the market's processing requirements for aluminum alloys, copper and other materials, we also published the ""three-flute round land three-relief aluminum carbide end mills"" (MU3-JMA series): the cutting edge of the carbide end mills adopts three clearances. Grinding, improve cutting performance, have a better processing surface, round groove full polishing treatment, effectively suppress the heat generated during processing, make the chip breaking stable, smooth chip removal, and extend the processing life.

Regardless of the products such as turning tools, milling cutters, carbide end mills or accessory sleeves, ECHAINTOOL team has continuously developed and innovated, developed various specifications, and the first-hand new product release information is visible to the official fan group (HTTPS). ://www.facebook.com/

Phone: +886-04-2271-0856

"

SUN FIRM MACHINERY IND. CO., LTD.

Product Description :

The latest Sun Firm CST-46160 is a horizontal CNC precision lathe offering high flexibility and processing efficiency. Our specially designed spindle accommodates up to two sets of mandrels at the front and back, which is perfect for processing long tubes or bars. The turret is designed to fit the rigid platform-type rail structure, providing the best balance between high cutting resistance and processing efficiency. The design of the body structure is complete and the interface is taken into account in advance. It can support the robot arm, the automatic power system as well as the power turret and lead to a more efficient treatment, bringing us win-win benefits.

EUMACH CO., LTD.

Product Description :

GVM-800U 專為高精度複雜多曲面銑削而設計,只需一次裝夾,甚至可以車削。從靜態剛性和動態質量的角度來看,每個關鍵部件的堅固框架都經過了很好的優化,以成為最高性能的天車式五軸加工中心。 雙Y軸驅動龍門型結構,絕對抑制了極高速(48m / min)加速/減速產生的振動。不僅可以提高生產前置時間,加工精度,還可以通過緊湊的設計優化工作環境,提高公司的整體管理水平。

直接驅動工作台由二個扭矩電機驅動,A和C軸各一個,最大速度50/100RPM,最大負載920/1200kg,旋轉角度A/C軸±125゚/ 360゚,達到新的高水平動態銑削和車削操作!

刀庫是由交流伺服電機驅動,以簡單,快速,無故障和極其平滑的刀具交換,標準32把刀及更多選擇。高速內藏式銑/車削電主轴18000~24000RPM可供選擇。搭配HEIDENHAIN TNC640,15”螢幕的五軸連動控制器,HEIDENHAIN高精度三軸光學尺,該加工中心用於飛機渦輪元件的加工及鋁製汽車輪圈高速表面處理提高了生產力。

RINGIER TRADE MEDIA LIMITED TAIWAN BRANCH

Product Description :

In a strategic editorial partnership with Germany’s Werkstatt und Betrieb & FORM+Werkzeug Magazine and a team of authoritative editorial advisors in China, International Metalworking News for China has been the leading trade media for China metalworking industry for over a decade - and remains committed to informing our readers of transformative solutions and technologies. International Metalworking News for China provides an interactive multimedia platform for our readers - the decision makers who include project engineers, R&D managers, purchasing managers, and marketing managers from the Aerospace & Aviation, Rail Transportation, Medical, Automobile, Energy, Mould & Die, Military, Electronics and Shipbuilding industries. The magazine provides in-depth coverage ranging from latest R&D, emerging market trends,updates on metal cutting and metal forming processes, the latest in machinery and use of materials, all in an interactive multimedia format for readers on the go.

The magazine’s multimedia format includes an interactive digital e-magazine containing many links to additional content, bilingual Metalworking verticals (www. industrysourcing.com/metalworking in Chinese and English) with daily updates and online exclusives, bi-weekly industry e-newsletters. Readers can also access this content through the “Industry Sourcing” Apps for both iPad/iPhone and Android mobile devices with video links on iTunes and Google Play. With such current, informative and attractive content in both digital and printed forms, International Metalworking News for China offers the most effective communication package to suppliers for improving productivity, reducing cost, and turning innovations into real competitive advantages.

HYDROKOMP GmbH

Product Description :

Coupling elements of HYDROKOMP are made of stainless materials. This enables the elements to be used for all fluids and gases that are not aggressive. Special designs eg. for water steam or other media are available on request. HYDROKOMP offers coupling elements for two different operating modes depressurized coupling or pressurized coupling. The elements for depressurized coupling can be coupled pressurized up to 25 bar, if the specified volume flow is not be exceeded. When using higher operating pressure there ockures a risk of demaging the soft seal in the check valve as the result of high flow velocities of the fluid. This means for coupling of air up to 10 bar there should be always used the coupling elements for depressurized coupling. This also applies when the coupling process is initiated pressurized. The elements which can be coupled pressurized may be coupled up to the maximum specified operating pressure on one side and / or on both sides.