Theme

Digital Transformation

Green Transformation

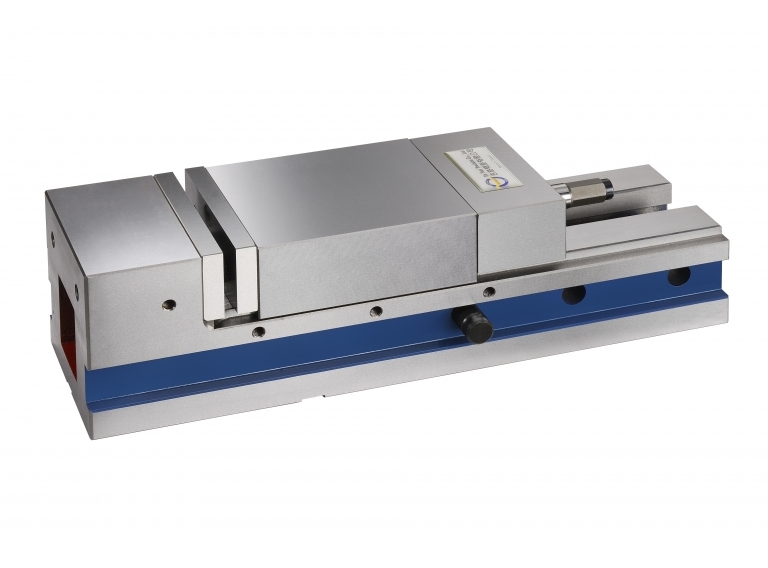

JIN YEAR PRECISION CO., LTD.

Product Description :

FEATURES:

1. Vise body is made of ductile iron FCD60.

2. Down thrust with"semi-sphere"to prevent work-piece lift.

3. Vise can side-lock to work.(Perpendicular of side lock

90°=0.015/100mm)

4. Vise bed hardened to HRC45° and maintain accuracy for long.

5. Vise slide-chunk can take out, Convenient to clean away chips and

inside of vise.

6. Vise bed height-size and guide block side are all made with full

control,can 2,3 or 4 vises to perform a job at a time.

TAIWAN MORE-CASH VILLAGE CORP.

Product Description :

For 2mm-34mm Twist Drill Re-sharpening , Angle 90°-140°

Easy to Operate , grinding a drill within 10 seconds.

Special Design High Accuracy Alloy Steel Collets

Accurate Grinding consumption 0.2mm

High Efficiency DC motor

Stable Quality Diamond Dust Grinding Wheel

Considerable Design, Invisible Tool Box, Delicate & Friendly Use

Portable Design with only weight 21.5 kgs for Machine, 13.6 kgs for Tool Box

QUASER MACHINE TOOLS, INC.

Product Description :

The MV1 series machines have a legendary history of high quality and proven performance, the New MV184 series has an even greater degree of reliability and performance. The design concepts of the new MV184 series combine advanced technology, performance and value for various machining applications.

Quaser produces this machine layout with the state-of-the-art digital design. Taking into consideration easy repair to reduce downtime. The MV184 series is the choice to increase part production.

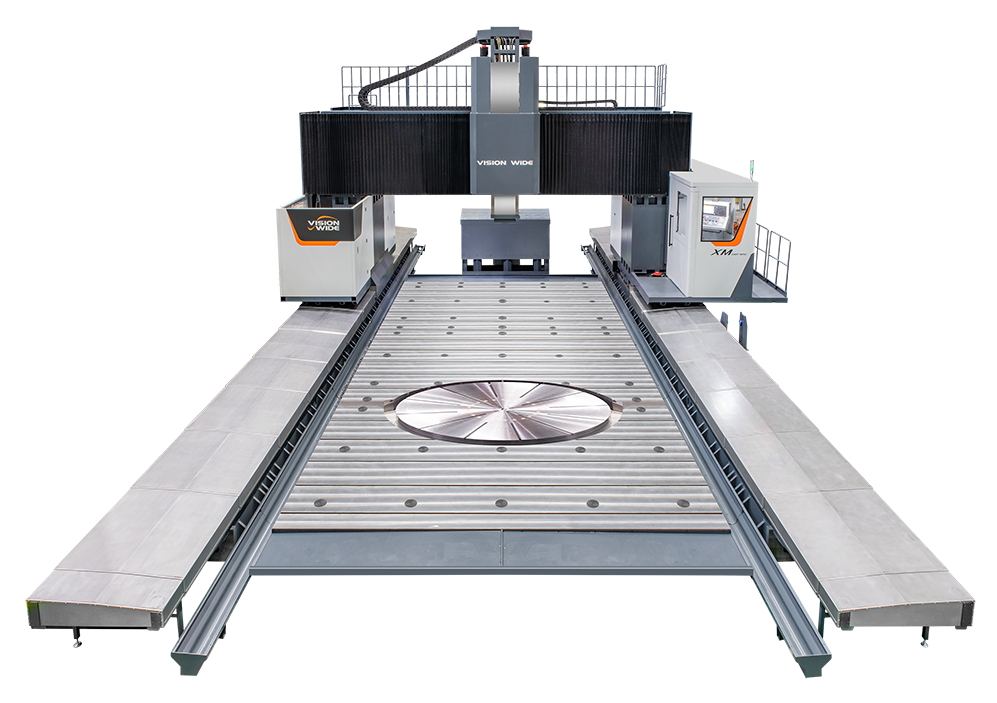

VISION WIDE TECH CO., LTD.

Product Description :

High Performance and Wide Application

XM series moving column machining center is a product developed for the machining needs of large-scale precision machinery, electric power, wind power, energy, petrochemical, transportation... and other equipment. It has:

Huge workpiece machining space: For precision machining of various types of structural parts, it can provide super large XYZ axis machining space.

• High-precise positioning: The high-standard geometric accuracy and positioning accuracy capabilities of the whole machine enable large-scale precision machining

• Heavy cutting capacity: Provide a variety of high-rated torque spindles to meet the processing and cutting capabilities of various materials.

• Fully automatic multi-face machining: This moving column machining center can be matched with various automatic attachment heads for high tangential speed mold surface machining and various types of precision parts complex angle machining, with excellent tool tip point error automatic correction function, and automatic additional head and tool exchange function, it can realize fully automatic machining performance.

• Milling and turning compound multitask: This moving column cnc milling machine can be equipped with a high-torque and high-speed vertical turning table to realize milling and turning compound automatic machining.

CIMer Tech co.,Ltd.

Product Description :

Distributed data management

Store, protect and deliver your most important messages

CIMer is a system specially built for the period from product development to mass production. From business orders, CAD product design, material creation, process review, and project management, it can be tracked and searched through any device. As long as you have a browser, you can Can participate in inspection and review of product design and development work.

system structure

Each region establishes its own Vault Server, and files will be synchronized between Vault Servers. Users can access the local Vault Server when accessing files. Users do not need to obtain the original CAD drawing files. CIMer provides converted graphics viewing formats (3D HTML/2D PDF), which can reduce the consumption of web page resources during viewing and improve transmission efficiency....

project management

Provide dynamic information on multi-project management at each stage during product development, such as Gantt charts, to assist the product development team in focusing on product development and improvement, and provide relevant timetables, human resources, output overview and distribution development periods during the period. , achieve better planning and utilization.

Design data and graphics management

Multi-CAD integration platforms, including drawing configuration, properties, versions, version management, combined drawing structures, parts and specifications/file associations of AutoCAD, zwCAD, Creo, Solidworks, Solid EDGE, Inventor, ZW 3D, NX, CATIA, etc., such as Approving documents, document version management, HTML format model viewing, 2D PDF document viewing, sharing drawings, BOM information based on design combination drawings...

Material Management Parts BOM/EC

After the product drawing design is completed, it enters the engineering proofing stage and related material information collection and management. Drawing files, material number correspondence, material attribute management, version management, association and viewing of materials and files, material BOM, automatic generation of material numbers, shared materials, etc...

Sign-off process management

Provide process system customization, and allow multiple people to collaboratively review all work that requires mutual notification, recognition, and review during the product development process. It is used at the review and notification level of the process and can be flexibly applied to the work processes of different departments and personnel.

Network collaboration

CIMer Web provides data viewing in non-Windows environments and implements the basic principles of ESG. Any device with a browser can participate in online process progress, such as inspection and review of product design and development work, paperless factory, post-engineering EC design change management from direct access of design drawings to manufacturing cells...

Message Center

Similar to the Outlook mail management function, it provides a message management center to manage notification messages, quickly jump from messages to related project work, and at the same time send emails to the mail server...

Over 20 years of experience in CIMe system development.

Over 300 case studies.

Visited more than 1,000 customer needs.

More than 200 customer satisfaction cases.

The CIMer system helps shorten your product time to market and significantly saves production costs and hidden losses.

KO-YAN PRECISE MACHINERY CO.,LTD

Product Description :

GJ-400 series from COMIRK combines internal grinding and cylindrical grinding in a single machine. Multiple face grinding can be accomplished with one setup for the work-piece. This machine not only saves considerable amount on machine investment costs and labor costs, but it also features dramatically upgrade for better machining efficiency and machining accuracy.

Machine Features

-Various speed of spindles selection allows for the highest grinding efficiency

-Double wheel spindles exhibit high efficiency internal and external grinding

-Internal, external, end face and tapered face can all be ground in one process

-Highly rigid machine structure ensures the best possible stability during grinding

-X, Y, Z axes are all mounted with high precision linear guide-ways.

-This machine is equipped with a FANUC CNC controller

-Multi-face grinding requires only one setup for the work-piece.

-Non-circular grinding function is available (Optional)

-Fully enclosed splash-guard

JASON AUTOMATION CO., LTD.

Product Description :

WRE(E) direct operated proportional directional control with integral feedback are available with or without on-board electronics (OBE). Positive overlap spools reduce leakage at center, while underlap spools can be utilized for closed-loop functions. Individual amplifiers are available, while OBE models are possible with either a voltage or current command.

TANKO ENTERPRISE CO., LTD

Product Description :

► 5"x2" PU caster

► Two fixed and two swivel casters with brakes with total 400kg loading capacity

► Standard Drawer: 95% extension with 45kg loading capacity

► Patented KPQ-B hanger hooks set (12pcs) and a perforated board

► Chamfer design to reduce injury

► Drawer latch

► Anodized aluminum drawer handle

► Metal handles

► PVC mat