Theme

Digital Transformation

Green Transformation

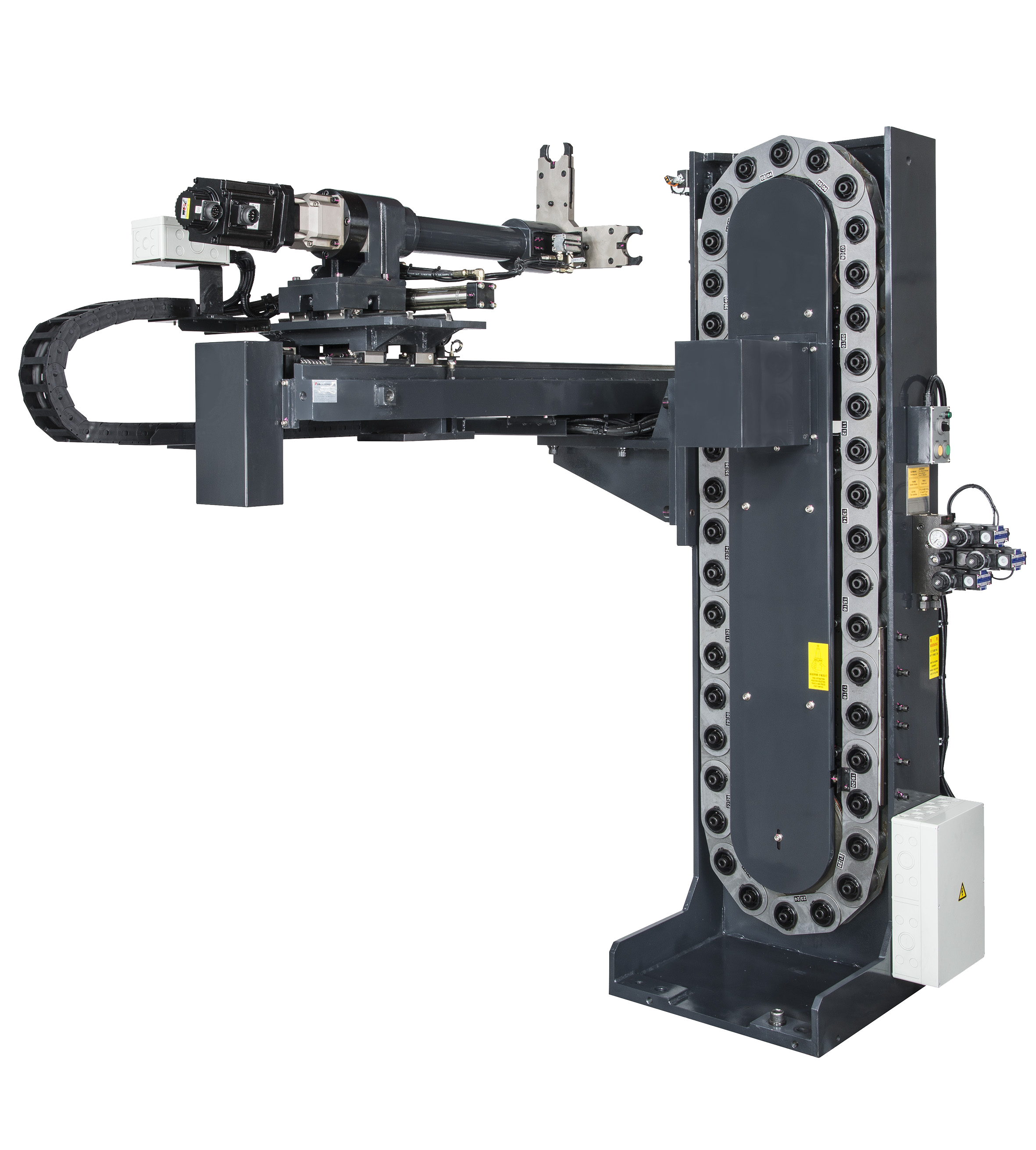

GIFU ENTERPRISE CO., LTD.

Product Description :

Applicable Specification:

BT40/CAT40/DIN40/HSK63/CAPTO6

Applicable Model:

Multi-Tasking Machines

1.The magazine can load 60/120/180 tools by front and rear allocation. Also, the magazine is adopted with high-quality and high positioning accuracy reducer and servo motor driven system.

2.The gripper replaces the tool pot to catch tools and achieve the purpose of lightweight and modularization

3.Innovative sub-tool pot tool catching system reduces 30% of the volume. The design of lightweight structure with fast moving speed achieves max. speed at 15m/min and the positioning accuracy of heavy loading is within ±0.1mm.

4.Two-stage advanced speedy tool changing system The best tool changing time can be adjusted according to different tool weights. The tool under 3 kg can complete tool changing procedure within 1 second.

TAIWAN 3AXLE TECHNOLOGY CO., LTD

Product Description :

Created to meet the demands of modern welding, MAXWELD combines a stylish appearance with outstanding performance. Focused on space optimization, it makes your workspace more spacious and efficient. MAXWELD is the world's first model to adopt a large-area airflow design, specifically designed for high-temperature environments within factory facilities. This unique airflow design ensures that the equipment maintains effective cooling even under high-temperature conditions. Additionally, MAXWELD comes equipped with dust-proof cotton to effectively prevent dust from entering, ensuring the stable operation and extended lifespan of the equipment.

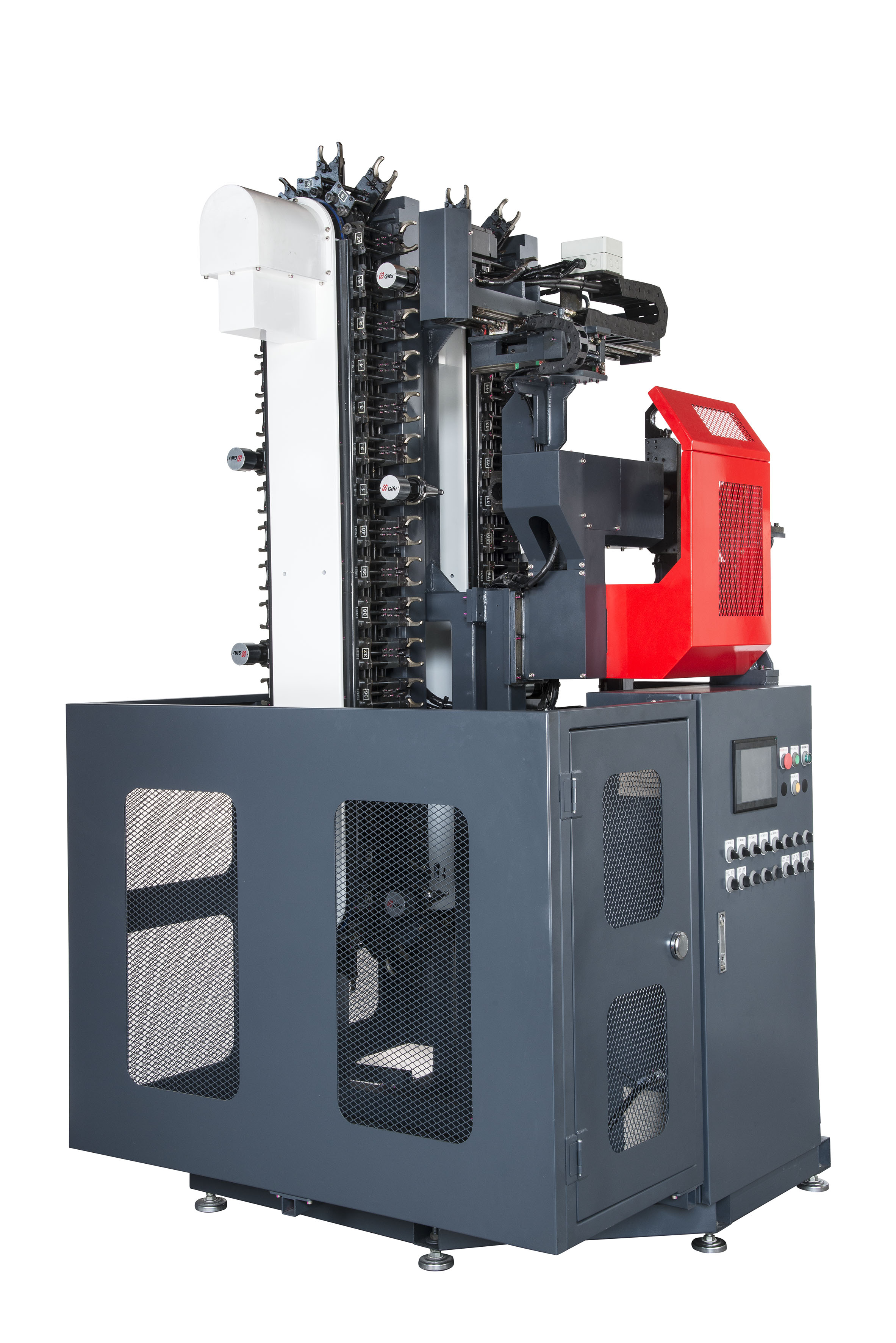

GIFU ENTERPRISE CO., LTD.

Product Description :

Applicable Specification:

BT40/CAT40/DIN40/HSK63/CAPTO6

Applicable Model:

Multi-Tasking Machines

1.L-shape arm allows speedy tool changing with short sequence. Besides, low swing loading makes long product service life.

2.The main chain wheel is driven by servo motor, which achieves accurate positioning, fast tool selection and multi-tasking tool management.

3.The long-distance movement is driven by servo motor, which achieves fast and accurate positioning.

4.Expandable tool storage.

BEST DIAMOND INDUSTRIAL CO., LTD.

Product Description :

Compared to resin bond and metal bond wheels, Electroplated Grinding Tools are noted for relatively large grit protrusion and higher abrasive concentration. This results in very free cutting properties and in high stock removal capacity. Besides, these tools are noted for:

1. Allow special shapes and profile tools to be made at short notice.

2. Cause very little change on wheel shape after used, suitable for precision grinding.

Application and Processing Material for Electroplated Grinding Tools :

1. Internal grinding: Suitable for the internal grinding of carbide and High Speed Steel. The smallest diameter of our electroplating area is 0.3mm so it could be used in drilling for fined ceramics.

2. Jig grinding: Mostly used in fined ceramics processing and precision grinding for quartz. Customized items are also provided to cater your needs. Common grit size is #80~#325, good for rough and fine processing.

3. Touchscreen Processing: Drilling and chamfering for the glass panel of the smart phone and tablet computer. In order to improve work efficiency, we could also combine different grit sizes in the same diamond mounted point.

4. Grinding for Cutting tools: Normal end-mill grinder and drill grinder go with electroplated wheel. Carbide can be ground by diamond wheel and High Speed Steel could be ground by CBN wheel. Bowl-shape wheel with standard specification is also provided, suitable for the grinding of turning tools.

5. Precision grinding: Electroplating can produce wheel of different shapes without deforming it. Therefore, it is suitable for precision grinding or trimming aluminum oxide wheel.

6. Gem grinding: shape grinding for gem, semi-precious stones, shell and jade.

Administration for Digital Industries, moda

Product Description :

多國語言四海矯龍CEO智慧行動商務系統(含外勤及主管)

1. 是可以善用手機聲音速記變成文字寫入CRM。用嘴巴說話可寫工作計畫。寫工作計畫及工作報告。寫出即時通溝通內容。

2. 外勤搜尋客戶的時候,連結雲端ERP客戶主檔位址用Google或百度地圖導航拜訪客戶及直接撥客戶主檔電話聯繫他到訪時間。

3 .外勤顧問到派工單指示地奌打卡簽到拍場景。會把當地経度緯度上傳雲端ERP_CRM 精確掌握外勤行動地址及回報工作內容。

4. 外勤行動在外可用手機查庫存,幫客戶下單當場請客戶確認。

5. 主管行動在外也可簽核估價單、銷貨訂單、請購單、採購單、請假單、會計傳票。出貨單,進貨單。

6. 主管隨時看各部門差勤到工人數,沒計畫做事之呆人、懶人、忙人,

7 .主管隨時看財務調度。工廠生產機台異常燈號警告。

RAISE PRECISION CO., LTD.

Product Description :

Capacitive switches with touch sensor technology

The first capacitive switches with touch sensor technology from CAPTRON were used in 1994 for public transportation. Today, CAPTRON offers a wide range of capacitive SENSORswitches for various industries and applications where unconditional reliability, durability, comfort and design are required.

If necessary, SENSORswitches from the standard range can be tailored and modified optically and technically to meet individual customer demands.

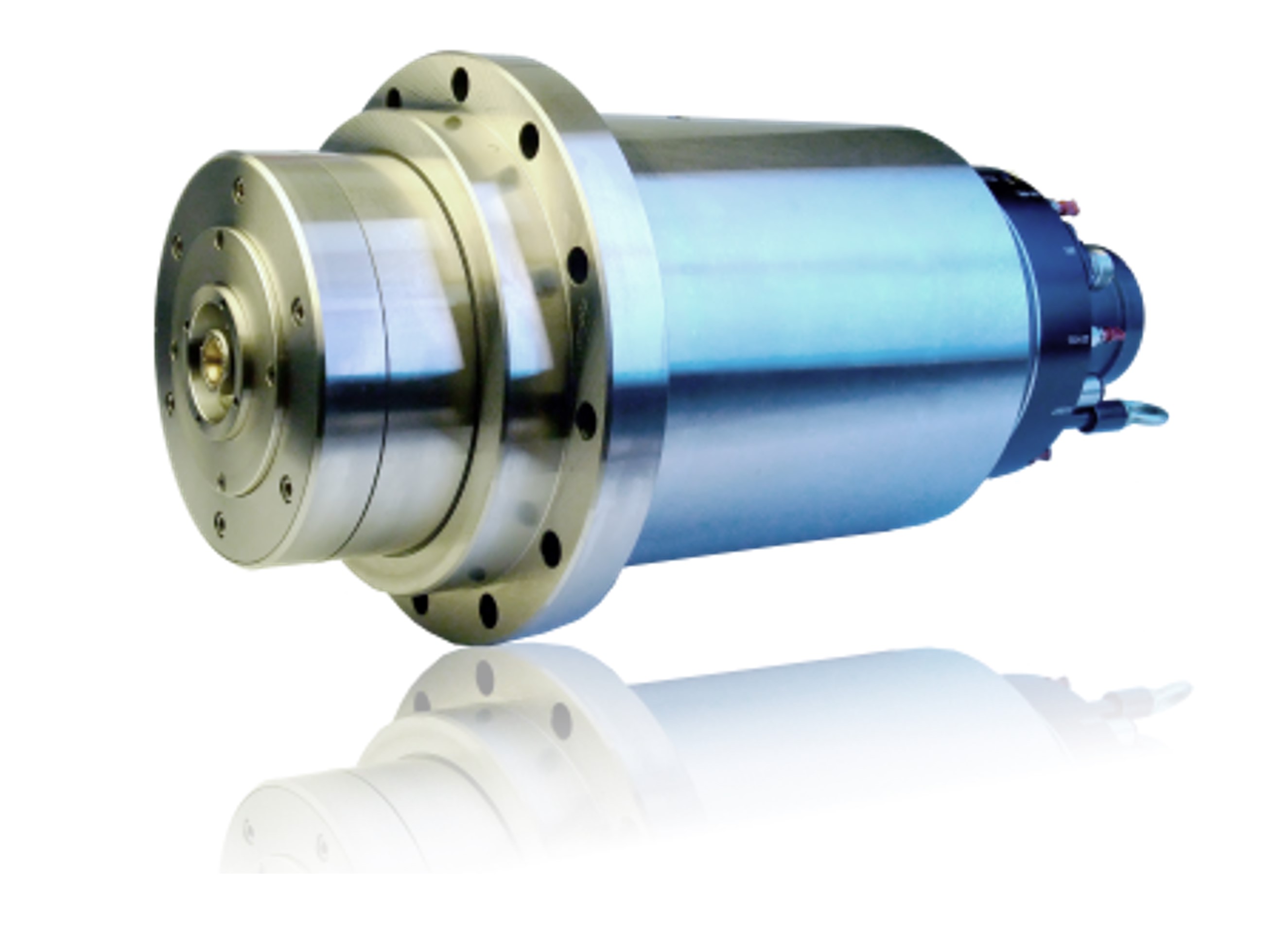

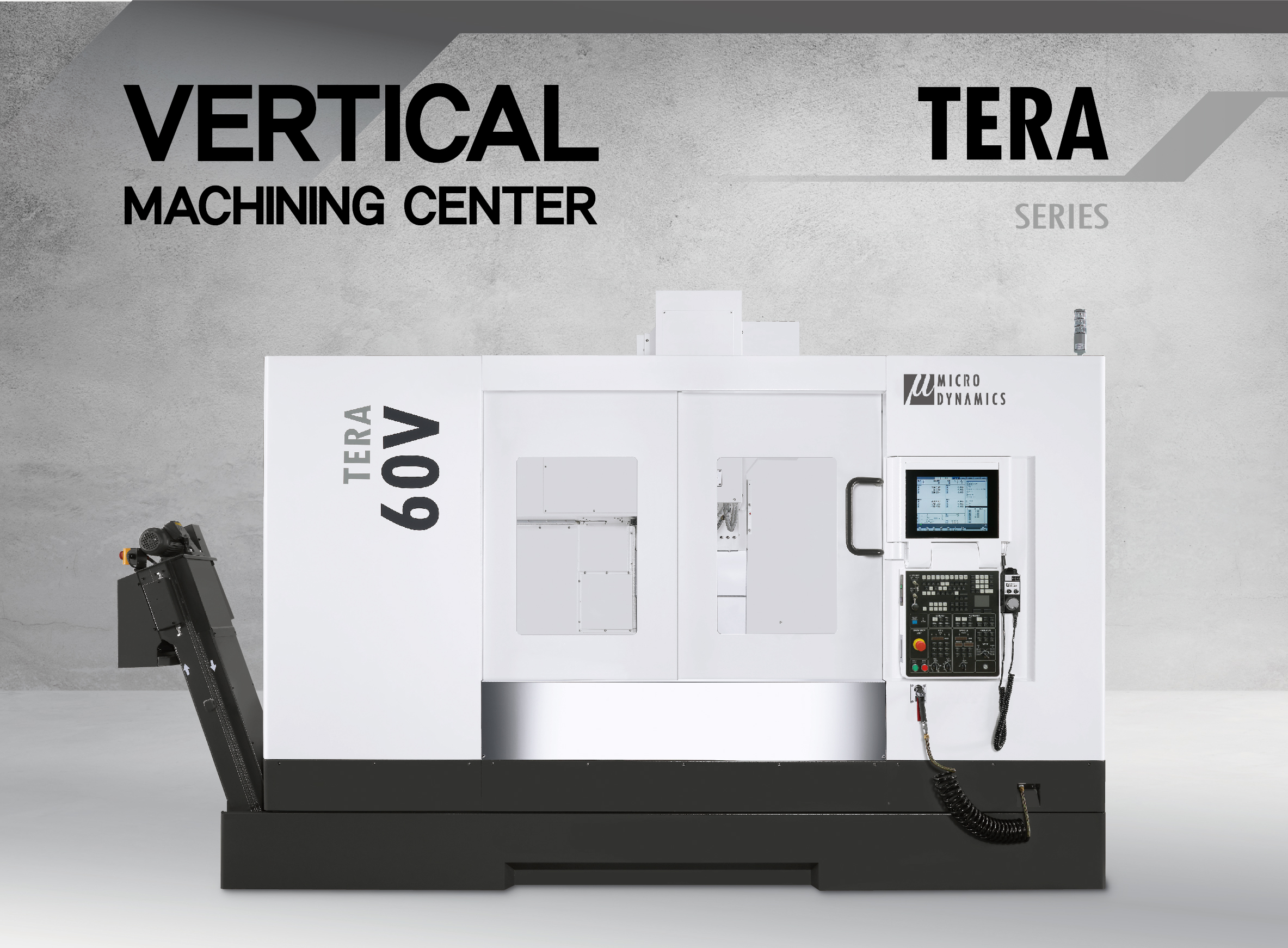

INNOSERV FA INC. TAIWAN BRANCH (BVI)

Product Description :

Micro Dynamics Vertical Machining Center Line opens a new era in multi-purpose and versatile machining centers. Compact, durable, powerful, strong and accurate, the MEGA/TERA Series starts a revolution in the market: the smallest C-frame machines provide powerful and precise results for manufacturers of dies and molds, aerospace, automotive, semi-conductor, job shops and general machine sectors.

The MEGA/TERA Series has been designed with the latest in technology being utilized throughout the machine with productivity in mind. From its EtherNet/IP architecture for easy automation and integration into systems and cells, to its Motion Control for fast and smooth operations used in all industries, the MEGA/TERA Series has quickly become one of the industries leading machine tool lines of Vertical Machining Centers.

The MEGA/TERA Series has been refined through years of research and development of new technologies that greatly enhance the machines for the rigors of the Mold and Die industry.

All series are equipped with

■ 15,000 rpm Built-In Spindle

■ Thermal Compensation (DYPEC)

■ Micro Dynamics HMI