Theme

Digital Transformation

Green Transformation

BUFFALO MACHINERY CO., LTD.

Product Description :

Available with two or six pallets, AXILE’s automated G6 Motorized Pallet Changer (MPC) exchanges raw workpieces and finished parts via a loading bay at the back side of the machine. Operators can load raw workpieces, and inspect and unload finished parts, while machining continues in the vertical machining center 24/7, dramatically increasing operational efficiency.

Freedom and flexibility are core to the design concept, as the MPC solution can be inte-grated upon initial commissioning of the G6 machine, or at a later stage when production capacity expands. And with the MPC-2 (the two-pallet solution), manufacturers can em-brace a Flexible Manufacturing System (FMS), of 12, 24, or 36 pallets total, by integrating one to three machines and two loading stations, depending on the scale required.

With AXILE’s digitalized intelligent automation solutions, manufacturers can eliminate production bottlenecks and ramp up production.

CLAMPTEK ENTERPRISE CO., LTD.

Product Description :

*High supporting force

CSP-P/ CSP-K increases the holding force between the piston rod and the inner jacket to arise the higher supporting force.

*Coolant cleaning measures

In order to prevent the malfunction from the intrusion of high-pressure coolant and the cutting dust entering the internal structure, air can be cleaned at the breathing port when replacing the workpiece. Air cleaning requires a dedicated air circuit. (recommended cleaning pressure is 0.3 - 0.5MPa).

*Universal piping base

CSP-P/ CSP-K piping base is interchangeable, which can be installed with other low-pressure cylinders in the same specifications.

IGUS TAIWAN COMPANY LTD.

Product Description :

免潤滑的滑動軸承技術——立即更換並將成本降低高達40%<br />

<br />

●免保養 iglidur® 滑動軸承<br />

透過免潤滑和減少保養工作來降低成本並增加使用壽命,所有產品均現貨供應——這是所有 iglidur® 工程塑膠軸承的核心理念和目標。 <br />

igus® 自潤式軸承系列包括套筒軸承、法蘭軸承、華司, 推力墊圈、活塞環、卡箍滑動軸承和眾多其他設計。 iglidur® 自潤式軸承總能給您解決方案——不論是目錄系列,還是訂製的滑動軸承特別解決方案,您都能找到適合自己的產品。 1件起訂。 <br />

iglidur® 自潤式軸承適合自動批量生產、特別機器製造、水下應用、食品或煙草業、極限溫度和耐化學品以及簡易金屬板安裝等應用。 <br />

<br />

●自潤軸承iglidur® PRT -工程塑膠回轉環軸承<br />

工程塑膠回轉環軸承<br />

自潤軸承iglidur® PRT是一款轉盤軸承,具有igus®工程塑膠軸承經驗證的優點。 由自潤軸承iglidur® 製成的滑動片是完全的免維護和免潤滑 轉盤軸承座零件是用鋁製成的,自潤軸承iglidur® J搭配的滑動元件表面經硬質陽極化處理。所有夾緊螺絲均為不銹鋼材質。 <br />

<br />

●xiros®工程塑膠滾珠軸承<br />

xiros® 塑膠滾珠軸承實現了滾珠軸承市場的革命性發展。 當傳統的金屬滾珠軸承不再滿足使用要求時,通過使用xirodur高性能工程塑膠,許多應用可以成功實現免保養和乾式運行。<br />

<br />

更多資訊: https://www.igus.com.tw/

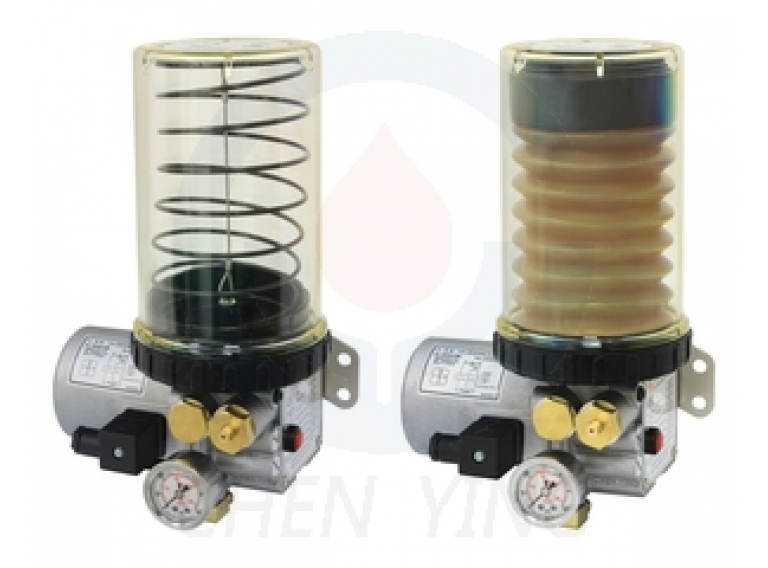

CHANGHUA CHEN YING OIL MACHINE CO., LTD.

Product Description :

1. KGC and KGCP types are suitable for grease NLGI grades 000, 00 and 0.

2. Recommend using a grease gun for filling with lubricant from grease inlet. It can avoid air or impurities dropping into the reservoir.

3. KGC and KGCP types are controlled by PLC (Programmable Logic Controller). It can work with CV type Progressive Feeders which can supply fixed volume of grease. CV type Progressive Feeders can assure each of lubrication point has equal amount of grease.

4. Pressure switch can be added on request for checking if the piping works normally. The standard setting is at 60 bars and the standard specification is NC (Normally Closed) contact, which means if the pressure doesn't reach the default setting, it sends continuous signals. NO (Normally Open) contact is available on request.

5. Magnet Level Switch is also an optional accessory that can be added upon request. It sends continuous signal automatically when the grease level is lower than the minimum level.

6. For the first time use, slightly press the Feed button (F button) to feed grease immediately. F button can be used as manually grease feeding for no more than 3 minutes.

7. AC110V and AC220V motors have thermal controls. When the motor temperature reaches 100℃, the sensor will be on to stop the motor continue running about 5 minutes.

8. It has a pressure gauge that the operator can check the pressure easily.

9. It can be used for the machines requiring strictly rationing grease flow. It usually works with rubber or plastic machines, press machines, machine centers, woodworking machines, etc.

FONGEI INDUSTRY CO., LTD.

Product Description :

-It can process various chips created by complex machining.

-Equipped with a filter system for processing cutting fluid with 0.5mm filtrating accuracy.The roller filter screen features a self-cleaning function to ensure the dependability of filtration.

-Equipped with an industry-leading overload protection device the extends the parts service life of the chip conveyor.

APEX PRECISION TECHNOLOGY CORP.

Product Description :

PVM-200 COMPACT CNC ENGRAVING & MILLING MACHINING CENTER

E CHEE MACHINE TOOLS

Product Description :

本產品使用中空刀桿與動態減震器,可吸收徑向與軸向的震動<br />

可適用市面上所有通用的铣刀盤<br />

本產品與相同長度的铣刀桿相比,可得到更快的切削進給及良好的加工表面精度<br />

FUTECH PRECISION CO.,LTD.

Product Description :

Ultra-short, large-diameter rotary hydraulic cylinder, lightweight design, more stable performance during high rotation, reducing spindle load.

The built-in safety self-locking valve ensures the pressure is immediately maintained during abnormal power outage and the built-in pressure relief valve.

Dual-purpose type, can be installed by the front and rear ends.

XIN GONG YANG MACHINERY CO., LTD.

Product Description :

◎Types: 12.5HP x 4P ;15HP x 4P

◎Designed for machine tools, including CNC heavy-duty double-column milling machines, dedicated machinery etc.

Cartell Chemical Co., Ltd.

Product Description :

我們的厭氧膠分為四大類:

◆螺絲固定劑:能完全填充螺紋之間的空隙,可以取代彈簧墊圈、雙螺母,及其他機械固定裝置,簡化產品的設計,並可防止螺絲扣件腐蝕、卡死、鬆動、滲漏、減少維修時間,永久確保螺絲裝配的安全,提高機械的穩固性。

◆圓形配件固定劑:主要應用於各種金屬圓柱型零組件的組裝。如:軸承、軸套、插銷、鍵槽、齒條、輪轂及滑輪等圓形配件的組裝固定,取代傳統的壓配、插銷、鍵槽等費時費力高成本的工作方式,改為簡易的輕壓配或滑配的方式。

◆管路密封劑:適用於金屬螺紋配管。它可以固定、密封金屬管路系統,填充金屬零件與螺紋之間的空隙,並防止洩漏、承受管路壓力、防止熱脹冷縮或震動引起的鬆脫和洩漏。

◆法蘭墊片密封劑:適用於各種尺寸的平面表面。它取代了傳統墊片,從而降低庫存成本。其特點包括無溶劑成分、高黏度、耐壓性和使用便捷性。相較於預先切割的墊片,其優勢在於簡化工藝、降低缺陷率、減少生產混亂,以及與多種黏著方法相容。

RINGTECH INSTRUMENTS CO., LTD.

Product Description :

IFP vacuum cleaning machine can effectively clean any size and structure of complex metal products, great for either large or small amount of cleaning, it is also the best vacuum cleaning machine available for environmental protection and energy-saving! The cleaning cycle is carried out in a complete vacuum environment that the working environment is clean and odourless. During operation, the user can select different options from spray, rotate, ultrasonic, rinse...etc. based on the workpiece. With the cutting edge iFP cleaning technology, overcoming difficult cleaning situations such as cleaning blind holes, slits can be effortless. After cleaning, the chips and residual cutting oil will be separated from the cleaned workpiece, the chips are fully dried and can be collected from the filter; the residual cutting oil will also be separated from water and could be recycled and reused.

Facing the new industry trend and the new future, IFP cleaning machine is your best cleaning choice!