Theme

Digital Transformation

Green Transformation

HABOR PRECISION INC.

Product Description :

> Applications

Grinding Liquid、CNC Cutting System、CNC Lathe、Other Machining Center

> Feature

Prevent deterioration of liquid.

Open coil type heat exchanger can prevent the obstruction problem of liquid circulating system.

Advance the speed of process.

Maintain the stability of dielectric fluid, advance the process quality.

Avoid fire risk cause by temperature rise and accumulating of dielectric fluid, advance the working safety.

Reduce the wastage of electrode.

Prevent the spreading of foul odor air, reduce the air pollution.

Easy operation and low noise.

Made of anticorrosive material.

LEADWELL CNC MACHINES MFG., CORP.

Product Description :

Twin spindle & twin turret design, it can turn the different parts on the spindle and identical parts on both spindles at the same time. Integrated with 3-axis robot arms, to reach different OP and automation requested. Considering the turning efficiency, with automation high-speed robot reduces the loading/unloading time, with a high rigidity stricture design to increase the stability. On the other hand, the multiple types of robot arms will be able to satisfy the different demands of the client.

Max. swing: 290mm

Max. turning diameter: 290mm

Max. turning length: 220mm

X-axis travel: 195+5mm

Z-axis travel: 300mm

Spindle speed: 3500rpm

Spindle nose: A2-6

Chuck size: 10"

Spindle motor power: 11/15kw

Number of tool stations: 12T

SUN FIRM MACHINERY IND. CO., LTD.

Product Description :

Machines are equipped with a product visualization. This remote monitoring system can check the life of machines' parts, spindle servo axis and tool. This device can report potential problems in advance and solve them, reducing cost and preventing waste of operational time.

Our specially designed spindle accommodates up to two sets of mandrels at the front and back, which is perfect for processing long tubes or bars. The turret is designed to fit the rigid platform-type rail structure, providing the best balance between high cutting resistance and processing efficiency. The design of the body structure is complete and the interface is taken into account in advance. It can support the robot arm, the automatic power system as well as the power turret and lead to a more efficient treatment, bringing us win-win benefits.

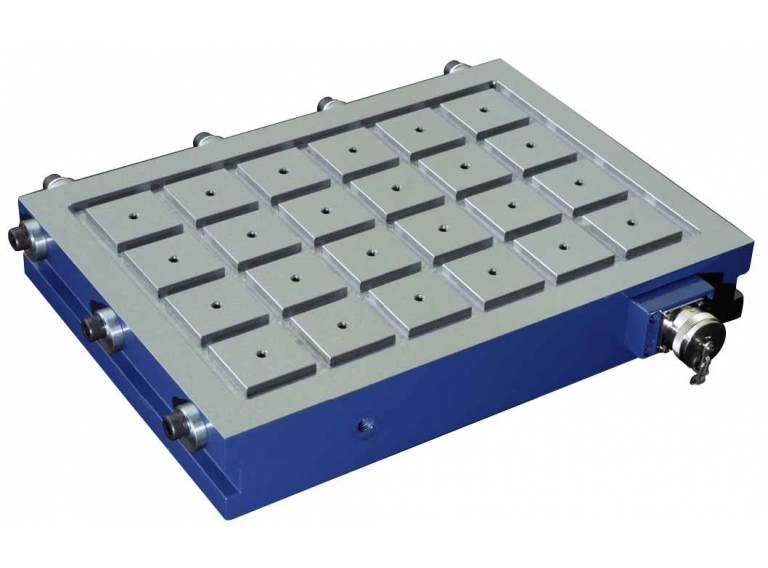

TAI CHONG CO., LTD.

Product Description :

用途: CNC切削中心機,銑床,龍門銑床,電腦銑床等切削作業。<br />

特性:<br />

本體與面板一體成型加工完成。<br />

以電控操作,快速充脫磁場變換。<br />

以永久磁鐵吸著工件,沒有停電的危險性。<br />

吸磁作業面,螺栓孔可應用於模具及固定方式的變化。<br />

可配合彈性導磁塊,針對變形平面,作平面加工,大量節省調整時間,提高工作效率。<br />

結構剛性佳,配合精度穩定,適合高精度加工作業。<br />

與強力型電磁鐵比較,大幅度節省電力消耗。<br />

防水效果最確實,保證不漏水,不漏電。<br />

平均吸磁力18kgf/cm2以上。

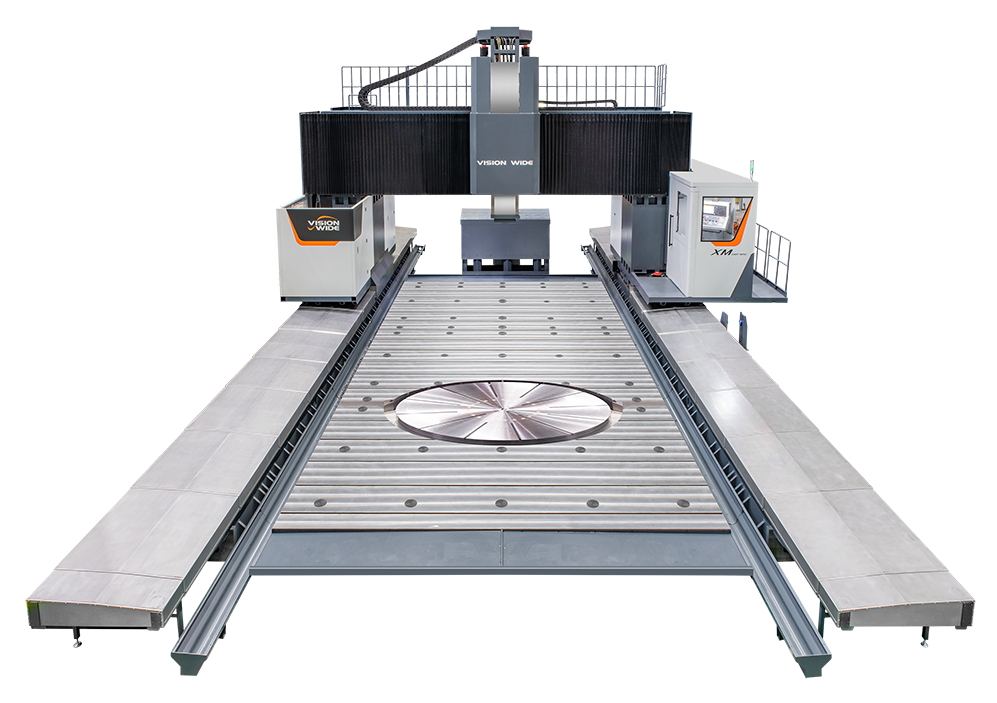

VISION WIDE TECH CO., LTD.

Product Description :

High Performance and Wide Application

XM series moving column machining center is a product developed for the machining needs of large-scale precision machinery, electric power, wind power, energy, petrochemical, transportation... and other equipment. It has:

Huge workpiece machining space: For precision machining of various types of structural parts, it can provide super large XYZ axis machining space.

• High-precise positioning: The high-standard geometric accuracy and positioning accuracy capabilities of the whole machine enable large-scale precision machining

• Heavy cutting capacity: Provide a variety of high-rated torque spindles to meet the processing and cutting capabilities of various materials.

• Fully automatic multi-face machining: This moving column machining center can be matched with various automatic attachment heads for high tangential speed mold surface machining and various types of precision parts complex angle machining, with excellent tool tip point error automatic correction function, and automatic additional head and tool exchange function, it can realize fully automatic machining performance.

• Milling and turning compound multitask: This moving column cnc milling machine can be equipped with a high-torque and high-speed vertical turning table to realize milling and turning compound automatic machining.

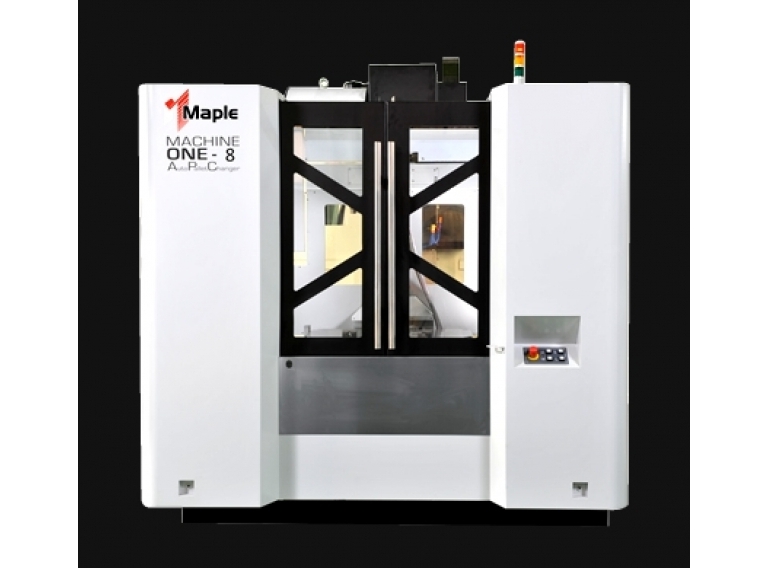

TAIWAN MACHINE TOOL CO., LTD.

Product Description :

The CNC Tapping center, designed and manufactured by TMT, is your best choice in drilling and tapping work. The machine series employs a high speed traverse on the three axes to significantly increase drilling and tapping efficiency. The entire machine is ruggedly constructed to assure the highest machining accuracy.

-The casting parts of machine are manufactured from high quality Meehanite cast iron, rib reinforeced and stress released to assure it remains deformation-free year after year.

-Three axes slideways are mounted with precision linear ways. Extra large span between ways. High feed rate and superior stablility.

-Servo motor directly drives ballscrew, featuring high positioning accuracy without backlash problem.

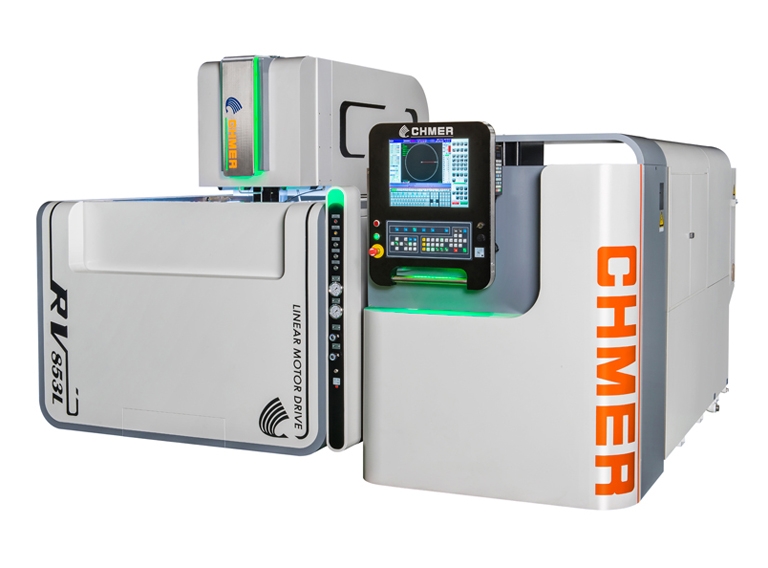

FAIR FRIEND ENTERPRISE CO., LTD.

Product Description :

1. Improve tools life and cutting efficiency, especially ideal for particular process requirements of brittle or hard、 high-temperature superalloy and composite materials.

2. Increased precision and quality of the workpiece to achieve excellent cutting results. (smooth edge)

3. Perfected ultrasonic control technology for easy selection, automatic frequency, and power adjustment.

4. The strong chipping of chassis concentrates the chips into the path as ensures high efficiency.

5. Anti-scale cover + KEVLAR armor material, used in glasses, ceramics super hard metal processing which can preventing dust protection system effectively.。

DEEP JET INDUSTRY CO., LTD.

Product Description :

1.Special cutting-edge design with low resistance to reach better chip-off from the groove. This shows the tool's stability in high speed machining.

2.The special coating enhances the anti-oxidation and wear resistance to increase high speed performance.

◆Carbide Drills With Internal Coolant Holes:

Internal coolant holes can highly increase the performance of cooling and chip removal rate.

◆Carbide Flat Drills:

Good for curve and inclined surface machinning.

HIWIN TECHNOLOGIES CORPORATION

Product Description :

The key components in Wafer Robot, such as ballscrew and direct drive motor, are manufactured by HIWIN, with Hiwin-developed software, HIWIN has the advantages of vertical integration of hardware and software. HIWIN Wafer Robot integrates the high-precision, high-rigidity direct drive motor with repeatability of ±0.1mm, small rotating radius and high space utilization. HIWIN can provide customized service according to production requirements and enhance customer competitiveness. Applicable to the semiconductor industry (wafer pick and place), optoelectronic industry (small panel, small solar panels), LED industry (sapphire substrate, rubber ring) and other pick and place equipment.