Theme

Digital Transformation

Green Transformation

R PLUS TECHNOLOGY CO., LTD

Product Description :

Japan imported high-precision CNC machining equipment

body surface after grinding or wire drawing process, the appearance of beautiful delicate

simple structure compact, ventilation volume

PARKSON WU INDUSTRIAL CO., LTD.

Product Description :

4 Axis MNC type.5 axisPAR(S) and DMTRT type.FMH type. 0.001° Horizontal CNC rotary table(2 table).FMHG type.1°Horizontal CNC rotary table(2 table).HMC type.0.001° Horizontal CNC rotary table(one table).HMGtype.1°Horizontal CNC rotary table(2 table).APC type. Vertical and horizontal auto pallet changer.SNC swing spindle head type.VLHI-hydraulic index table.FMS-multi-pallet changer type.

LNC TECHNOLOGY CO., LTD.

Product Description :

• 7” touch screen

‧EtherCAT protocol provides high flexibility of peripheral equipment connection control

• All-in-one design: pendant integrated with control unit

• IP65 waterproof and dustproof protection

• Magnetic back fixing bracket

• Electronic hand-wheel design to machine tuning, facilitate adjustment and program dry run

• Support multiple types of robots: Six-axis, Delta SCARA or customized special type robots.

• Axis control: six-axis(for robot itself) and additional three axes (for external accessories)

• Application: Polishing robot, spraying robot, welding robot, handling/palletizing robot

Hantop Intelligence Technology

Product Description :

Tool Holder Spec. provided:

BT30, BT40, HSKA63, HSKE25, HSKE32, HSKE40, CAT40

1. High Speed, high efficiency ultrasonic machining solution for high precision advanced materials machining(can reach 38000 rpm)

2. Plug and Play design for convenient and flexible Installation

3. Effective Intelligent Tracking System for advanced materials machining, finding the suitable resonance between tools and modules

4. Non-Contact transmission Design doesn't limit the high spindle rotation and reduce the impact from cutting heat, enhancing tool life and quality to next level.

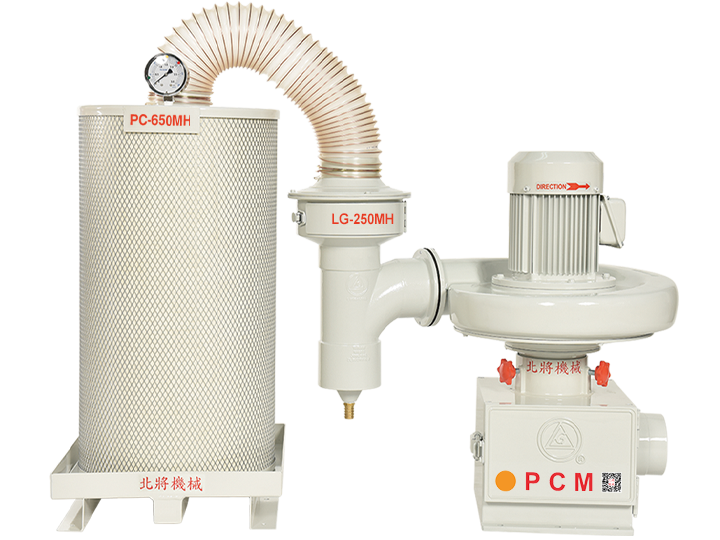

PEI CHIANG MACHINERY CO., LTD.

Product Description :

北將機械公司專業處理油霧油煙、油氣已有20年經驗,新推出M系列油霧回收機及分離式油煙處理座,擁有專利設計,可直接安裝,多功能彈性化組合,能因應不同的生產環境需求。

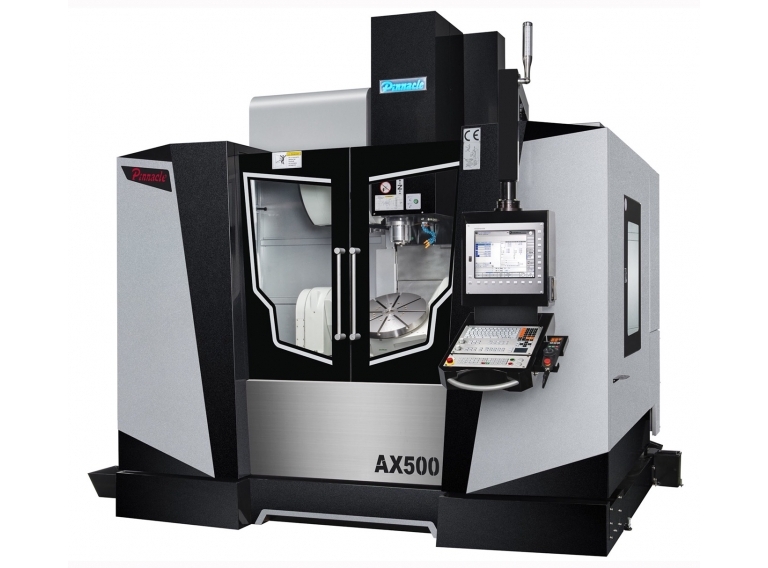

PINNACLE MACHINE TOOL CO., LTD.

Product Description :

嵩富AX500為高精度、高剛性5軸綜合加工機。A/C軸採用DD馬達直接驅動,最大工件尺寸可達Ø700x350mm (500公斤),A軸傾斜角度220° (-110°/+110°), C軸盤面Ø500mm可一次完成複雜、多面、曲面工件的加工,以減少加工時間。X/Y/Z標配中空油冷滾珠螺桿,以減少運作中熱變形,搭配A/C軸光學尺以達到高精度加工需求。<br />

<br />

X/Y/Z三軸採45mm滾柱型線軌,X/Z軸有6個滑塊等高剛性結構設計。採海德漢控制器TNC640,可作5軸同動加工,讓 AX500成為最符合3C、模具、醫療、航太、汽機車零件加工需求的5軸綜合加工機。<br />

A Being Kou Tools Co., Ltd.

Product Description :

After becoming frustrated by the existing coolant hose products on the market; all of which suffered from a variety of shortcomings, Arnold Lockwood conceived the idea for the modular hose that became Loc-Line®. The shortcomings of the existing products included, metal coolant hoses that would not stay where they were positioned and plastic hoses with metal positioning rods that broke.

In 1981 Lockwood Products was formed to develop and distribute Loc-Line®. The first products were shipped in August of 1983.

Loc-Line® quickly became the standard for coolant delivery around the world and was easily recognized by our Blue and Orange colors and consistent high quality.

Today Loc-Line® is still the leader in modular hose and continues to innovate in the modular hose field. Loc-Line® is used not only as a coolant hose but for air delivery, smoke and dust removal vacuum systems, agriculture, third arm uses including positioning cameras, lights and items for handicap assist.

We here at Lockwood Products, Inc are proud to have originated the modular hose Loc-Line© that remains the standard for the industry worldwide!

Please visit one of our distributors today and see for yourself why Loc-Line remains the best and most versatile solution in the world today!

HAI JU TRADING CO., LTD.

Product Description :

High-strength connection and maximum sealing

Can you imagine high-quality products without screw connections?

Modern technology cannot do without them as detachable joints. In the industrial

sector, fluid technology, pneumatics and sealing technology are among the fields of

application. In those sectors, often additional functions such as sealing, insulation or

reuse of bolts are required – only to mention a few.

One classic example are adjusting screws on hydraulic components, steering boxes

and fuel injection pumps. For those applications, high-strength screw connections

with reusable bolts and sealing against leakage are essential. We provide the solution

that fulfils those high requirements: the SEAL LOCK® sealing nut. It prevents any

unwanted leaking of gaseous or liquid media. The SEAL LOCK® ring integrated on

the nut helps to achieve reliable sealing inside the thread without the use of

additional elements. It is reliable in two ways because it seals under the head and

inside the thread. Not to mention the easy installation.

The following figures show conventional solutions on the one hand and the

SEAL LOCK® sealing nut on the other hand.

TES ELECTRICAL ELECTRONIC CORP.

Product Description :

FEATURE:

Compliant with IEC 61672-1 class 1 standard

Dynamic range of 90dB

AC and DC outputs

Data transfer using USB

microSD card

Real-time 1/1-Octave and 1/3-Octave analysis

Measurement can be started by internal or external trigger

Comparator output to trigger external devices

Super high – contrast backlight TFT – LCD color display

VISION WIDE TECH CO., LTD.

Product Description :

One of the proudest products of Vision Wide which fulfills automatic 5-face machining with super rigidity structure and high positioning accuracy. HF satisfies demands in mold surface cutting, angle cutting, 3D mold cutting, and precise contour finishing.

GRINTIMATE PRECISION INDUSTRY CO., LTD.

Product Description :

a.Equipped with the exclusive hydrostatic spindle.

b.Equipped with the exclusive hydrostatic guideway .

c.The grinding wheel can be widened to 300mm with one-feeding grinding.

d.Headstock and tailstock both work with double sided synchronous.

e.Our products are on hundred percent designed and manufactured in Taiwan. To guarantee the stability of machine, all of the cast components go through a pressure relieve process