Theme

Digital Transformation

Green Transformation

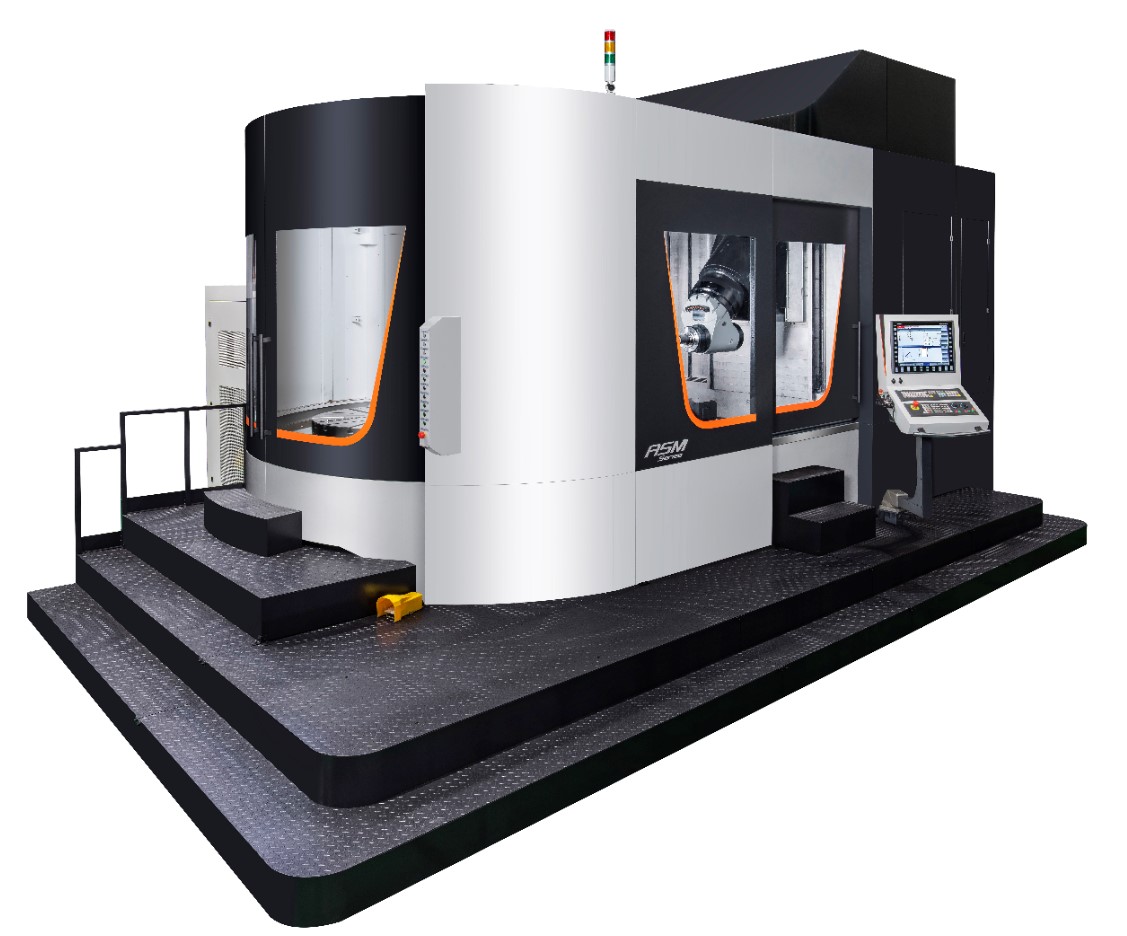

VISION WIDE TECH CO., LTD.

Product Description :

• ASM is the first 5-axis CNC turning and milling machining center of Vision Wide, and it is particularly designed for delicate cylindrical components machining featuring high acceleration, rapid feed-rate and synchronized axes machining, especially for aerospace components, tire molds, turbine blades and aluminum parts.

ASM accessorizes with 5-axis universal head and rotary shafts built-in D.D motor. Through topology analysis, ASM realizes the best distance between tool center point and B-axis transmission

• Positioning P0.006mm

• Repeatability Ps0.0055mm

• Spindle thermal compensation 0.02 mm

• Rapid Traverse 40m/min

• Acceleration 0.3G

• Cutting Feed rate 24 m/min

JAR HON MACHINERY CO., LTD.

Product Description :

1.Attached with multi head which can drill many parts at the same time in order to enhance efficiency.

2.Design a complete unit of multi head, guiding hole plate and jig in order to have high accuracy.

3.Suitable for reaming, drilling and chamfering.

4.Optional functions: "Auto. discharging chips" and "Auto. breaking chips".

PHD Books Co., Ltd.

Product Description :

機械雜誌的第一品牌

充滿未來性之「機械新刊」具備三點特色:

第一,「選對的主題」。機械新刊每月所挑選的文章,都是對機械產業非常重要的指標性主題,多元化的內容整合,適合讀者每月翻看,汲取新知。

第二,「用對的人」。機械新刊之主編群結合產、官、學、研各界專家菁英,提供最優值的文章和綿密的產業資訊。現在是知識經濟的時代,在知識情商方面,哪一家公司有新產品?哪一家公司有好技術?透過機械新刊廣大的客戶產品資訊,讓您在通路行銷,研發製造各方面都能領先群倫。

第三,「做對的事」。機械新刊的市場定位及聚焦策略,考量傳承與創新之間的平衡,希望雜誌內容能兼顧廣度與深度,除了持續保持專業文章的深度,更重要是與市場貼近,完全掌握市場脈動,同時加入人文的溫度。

2017年起,博士文創事業經營機械新刊,以「廣遞新知,用心規劃」為宗旨,努力建立遍及海內外的讀者群。我們計畫以台灣為中心,向海外拓及讀者群,讓所有華語專業人士,都能翻閱機械新刊,從中獲得想要的資訊。另外,我們要使刊物成為客戶最佳的行銷利器。我們充分瞭解客戶的需求,讓機械新刊成為情資收集的專業平台,展示產品的最佳舞台。機械新刊紙本刊物搭配電商規劃,讓廠商在數位時代,將有更高更長久的曝光。

機械新刊充滿前景,「選對的主題」、「用對的人」、「做對的事」,我們的團隊專業,充滿競爭力,發行人出身機械產業,親身投入用心經營。機械新刊才剛要開始發光發熱,我們有絕對的信心,成為機械雜誌的第一品牌。

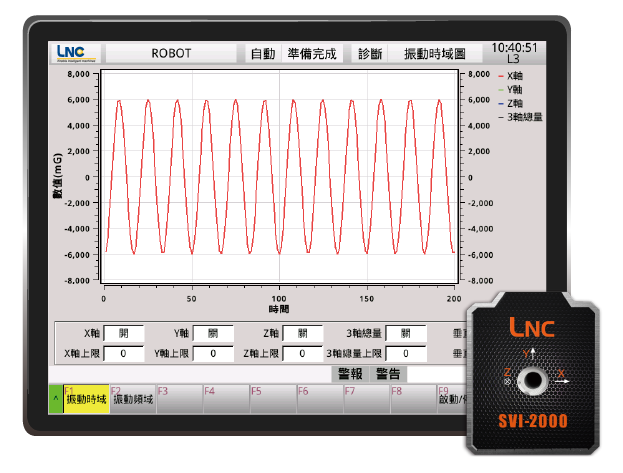

LNC TECHNOLOGY CO., LTD.

Product Description :

‧Low profile, high performance, easy installation, high applicability

‧High sensitivity, high precision

‧measurement:±16G, extremely low signal /noise ratio

‧XYZ three-axis vibration detection

‧Measuring frequency 3.32kHz(max.)

‧EtherCAT protocol

‧Water and oil proof, great anti-interference ability

‧Support time domain graph, frequency domain graph, abnormal vibration section marking of program function

‧Support smart function development: Broken tool detection, abnormal vibration detection, spindle protection, tool wear, adjustment assistance, equipment health inspection, etc.

CHING HSYANG MACHINERY INDUSTRY CO., LTD

Product Description :

1. This machine is designed for internal and external shaving of round

tubes.

2. The center line of the processed object and the insert head is accurate.

3. The clamping die and the insert head are designed to be uniform, and

the work piece can be processed uniformly at one time.

4. The insert head is specially designed, the blade is standardized, and the

adjustment tool is simple and fast.

5. Feeding by manual, automatic advance and retreat blade, fast speed,

suitable for material steel pipe, iron pipe, aluminum pipe, copper pipe,

stainless steel pipe, plastic pipe, non-metal material and carbon fiber

pipe.

6. The machine is randomly matched with the multiple clamp, which can

be applied to different pipe diameters, saving time and cost for

replacing the clamp.

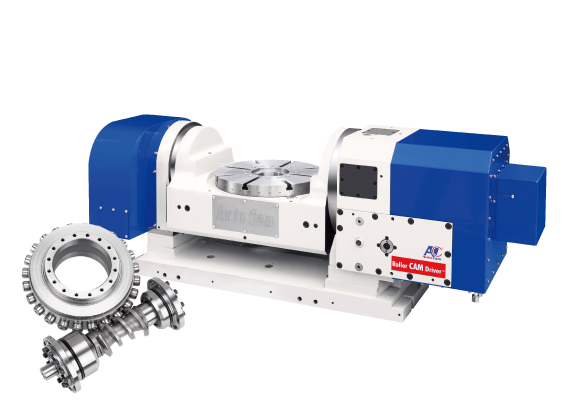

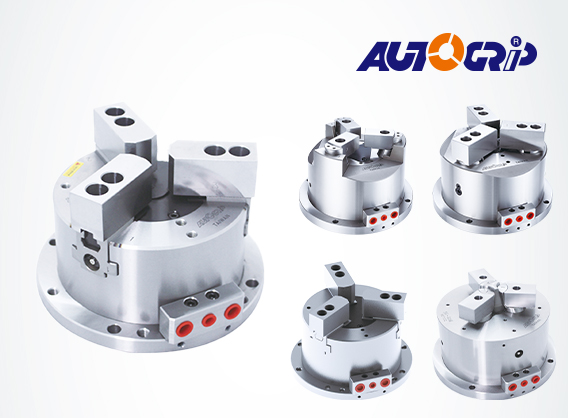

AUTOGRIP MACHINERY CO., LTD.

Product Description :

For stationary chuck, there are pull back, pull lock, thru-hole/non-thru-hole stationary chucks in the category.Multi-plate.4-plate(MP4)=>

For milling machine / machine center.

Allow simultaneous machining with up to 4 grippers.

(Order can be customized for 2,3,6 grippers).

Work with SP/SD/SU/SE vertical chuck.

Driven by Hydraulic or Pneumatic.

Individual circuit for each chuck.

Special design and reduce the height of working surface.

Lock valve unit (option).

Air tight detection function(option).

AUTOCLAWS PRECISION MACHINERY CO., LTD.

Product Description :

1. Suitable for round-bar shape objects to clamp before cutting process.

2.Using the advanced high-strength alloy steel, the key components have been treated with hardening which is strengthening the structure and enhancing the stability with accuracy and durability.

3.Large caliber design allowing the bar material go through, furthermore, it can be complemented to automatic processing eqipment for enhancing the machining efficiency.

4. The chucks complement the rotary hydraulic cylinder to provide a stable pressure for various chucking conditions.

5. Professional precision grinding makes it high-precision, precision repeat clamping accuracy, high clamping force.