Theme

Digital Transformation

Green Transformation

LEEKA INDUSTRIAL CO., LTD.

Product Description :

LEEKA manufactures all kinds of leveling feet and heavy duty wheels. Our product category included leveling legs, adjustable leveling feet, industrial caster wheels and leveling casters.

Commonly used in industrial cabinets, transportation, compressors, generators, food industry equipment and so on. All products can be customized according to customer demand for different sizes, specifications and materials.

YOKE INDUSTRIAL CORP

Product Description :

1. Size from M8 to M90 to fulfill your demand

(M8 ※ 0.3t _ M90 ※ 40t)

2. Design Factor 4:1, Working load limit could be up to 40 tons

3. Lifting point is made by forged alloy steel, quenched and tempered

4. Suitable for all loads which swivel and tilt especially for heavy duty, material handling, mold & die industries.

5. Ball bearing inside is easier for flipping working piece and rotation.

6. Light weight, High Performance, easily for using

7. Deliver with test certification to guarantee your safety

OSCAR E.D.M. COMPANY LTD.

Product Description :

1.Windows 10 Operating system with industrial CPU i3( or above)64-bit.

2.21.5" multi-touch screen with movable controller.

3.Equipped with digital voltmeter, current meter etc., to monitor the machine status easily.

4.Up to 6 axes control - XYZCUV - equipped by rotary table to satisfy complex job.

5.Color touch-screen on remote controller, unique design improves user convenience.

6.ECO stand-by mode: Equipped by a motion sensor for power saving.

PRECISION MOTION INDUSTRIES, INC.

Product Description :

●Equipped with lubrication unit G1, it can reduce the amount of oil used to meet the economic and environmental protection needs in response the carbon reduction trend.

●In required clean environment where it is necessary to avoid oil scattering, and also prevent to temperature rise caused by injecting too much oil.

●Contains more than 70% oil and can run more than 20,000km without oil supply, also easy to supply oil in difficult filling places and saving a lot of maintenance time.

●Even in an environment with water, there is no need to worry about oil and grease being washed by water.

●The extra lubrication unit equals an extra layer of scraping effect, which greatly reduces the chance of foreign matter invasion.

CHUAN TAI HYDRAULIC MACHINERY CO., LTD.

Product Description :

The oil return filter is mainly installed on the oil return line of the hydraulic system. Various impurities such as abrasive particles generated during the work of various hydraulic components can be blocked by setting the oil return line to filter and avoid returning to the tank again.

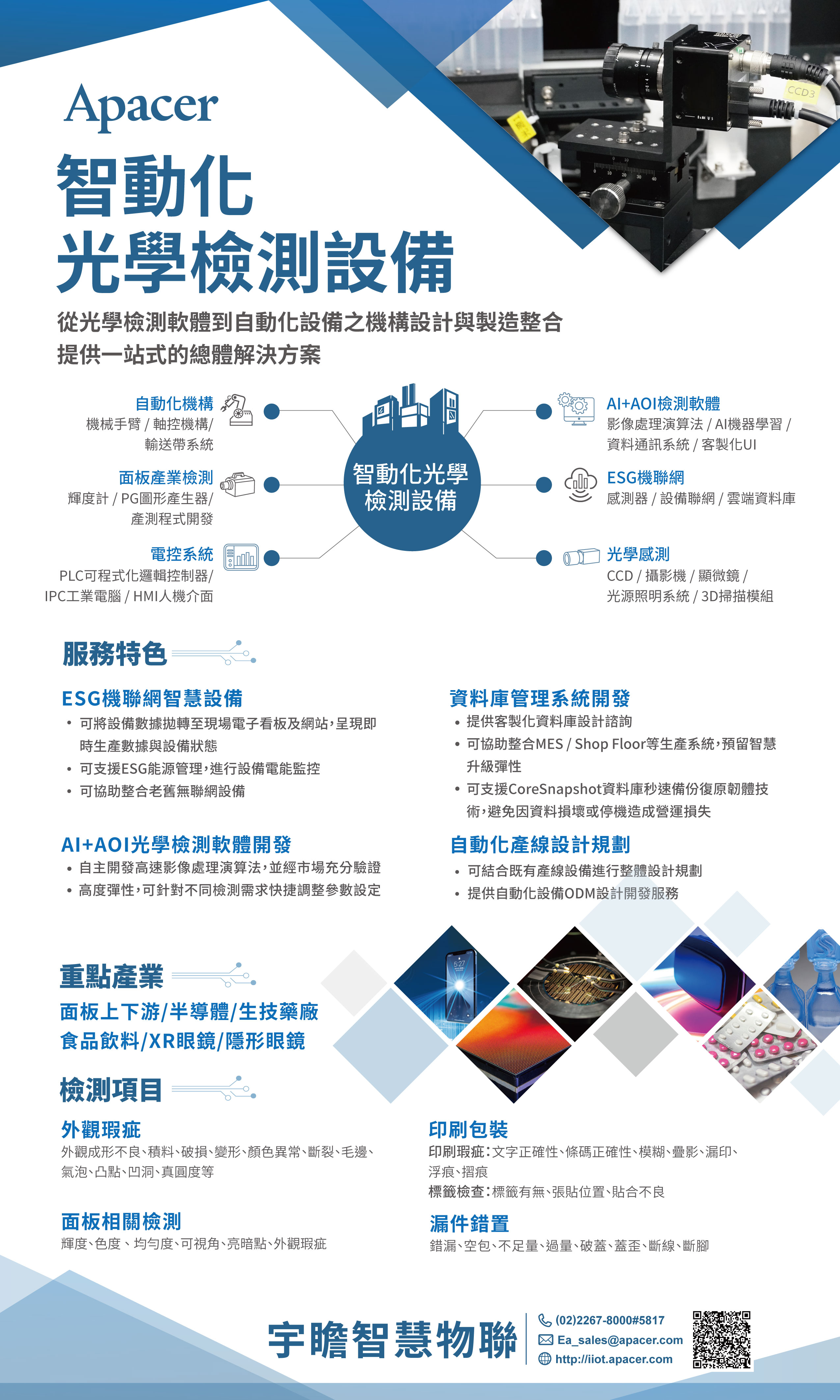

APACER TECHNOLOGY INC.

Product Description :

從光學檢測軟體到自動化設備之機構設計與製造整合

提供一站式的總體解決方案。

客製化規劃,專業設計開發AI+AOI光學檢測機台,可串連現有機台,設計全新自動化流程,提升瑕疵檢測的效率、降低人力成本。適用於面板業、生技藥廠、半導體、食品飲料等產業的各式瑕疵檢測應用。

瞭解更多:https://iiot.apacer.com/tw/optical-inspection/ai-aoi-automation/

更多實績案例,歡迎參考Apacer宇瞻智慧物聯官網:https://iiot.apacer.com/tw/case-studies/