Theme

Digital Transformation

Green Transformation

RINGIER TRADE MEDIA LIMITED TAIWAN BRANCH

Product Description :

International Metalworking News for Asia (IMNA) print magazines, digital e-magazines, and fully interactive magazine Apps with video links on iTunes and Google Play facilitate technology transfer by providing readers with industry news and trends. For over 10 years, IMNA has been providing readers in Asia practical solutions for improving productivity, reducing cost, and turning innovations into real competitive advantages to advance their operations.

These readers depend on IMNA for detailed technical information for real-world applications Metal Cutting, Lasers, Tooling & Workholding, Software & Control, Metrology, Welding and Metal Forming & Fabrication that can help them develop their business planning and strategies, product quality, process stability, equipment reliability, operator safety and business profitability, as they take advantage of the emerging opportunities from the Asia region.

Our editorial partners include Ringier’s family of Metalworking magazines covering the Greater China and a team of authoritative editorial advisors throughout South East Asia.

For suppliers, International Metalworking News for Asia is an effective multimedia platform which provides the latest information on their products and services. Through a dedicated Metalworking vertical, the industry community can find daily news updates and exclusive online features, videos and reports on major industry events – including live updates from trade shows as they happen – to keep the industry stay informed. Bi-weekly E-newsletters featuring headline industry news, trade show coverage, and analysis and market reports keep you linked to the industry with your latest company information.

HAWE Hydraulik Singapore Pte. Ltd. Taiwan Branch

Product Description :

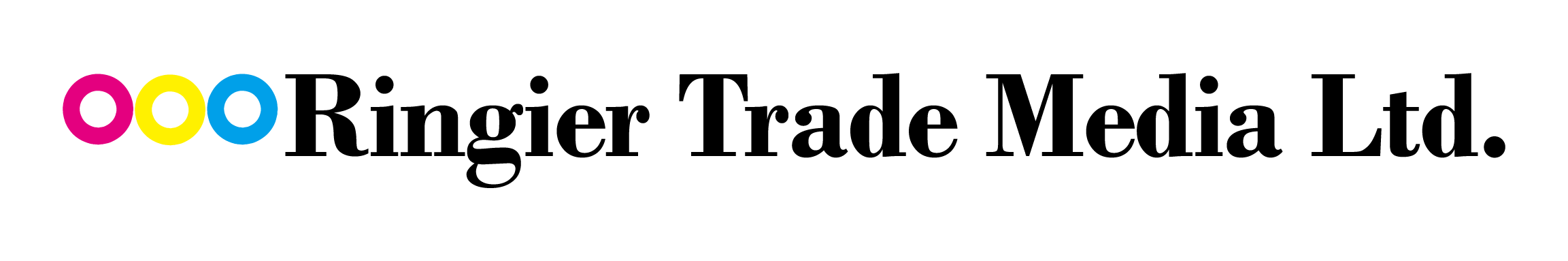

Directional seated valves are a type of directional valve. As cone valves they are tightly sealed, with zero leakage in the closed state.

The directional seated valve type ROLV is available as a 3/2, 4/2 or 4/3-way directional seated valve with different plug types. The patented assembly consists of two parts: a round basic valve with the valve inserts, and an adapter plate which can be designed for manifold mounting with nominal size NG 6 as the

standard connection pattern, or for direct pipe connection.

Additional elements such as a check valve, a restrictor (on the consumer side) and/ or restrictor check valves can be integrated, depending on the functional requirement and adapter plate. The type ROLV can be combined in the valve bank type BA with other types of valves.

Features and benefits

■ Dirt-resistant design with high switching reliability

■ Interchangeable solenoid for greater flexibility and easy servicing

Intended applications

■ Machine tools (cutting and non-cutting)

■ Clamping tools, punching tools, fixtures

■ Testing machinery

■ Wind turbines

BLUM PRODUCTION METROLOGY CO., LTD.

Product Description :

– THOUSANDS OF MEASURING VALUES OF ALL TOOL CUTTING EDGES PER SECOND

– UP TO 60% LESS MEASURING AND CHECKING TIME

– MEASUREMENT AND MONITORING OF ALL KINDS OF TOOLS, TOOL FORMS AND CUTTING MATERIALS

– COMPENSATION OF SPINDLE DRIFT AND TOOL CUTTING EDGE RUN-OUT ERRORS

CENTURY TRADING CORPORATION

Product Description :

Android, the machine divelopped with a concept "pursue actual machining accuracy within ±1μm"

Suppressing thermal displacement at minimum under high speed machining condition,

tuned up to attain higher machining accuracy to satisfy additional requests from customers,the next generation of Android has been finally released.

This is Ultra Precision and High-Speed Micro Fine Machining Center,

FINTEK INDUSTRY COMPANY LIMITED

Product Description :

Initial pinch 3-Roll plate bending machine

Affordable single pinch bending application, flexible use of small space workshop

3 rolls camber designed with hardness HRC 50-53 degrees, dealing with various material processing

Build in high quality hydraulic system with overload protection

The first choice for petty workshops or personal studio, small invest and fast get back

PALMARY MACHINERY CO., LTD.

Product Description :

High grinding accuracy and high rigidity design for 4 axes CNC Centerless Grinder bearing spindle type.

Double-side slides design allows to equip the infeed grinding type device, also could arrange the optional high speed auto loading & unloading attachment.

The best configuration for machine bed and structural support ribs makes the grinding accuracies has high stability.

The customs design loading device and outer diameter measuring device are also possible as optional for best functional performance.

The grinding wheel spindle single bearing holding type equipped with super precision cylindrical roller bearings for the highest rigidity requirement.

The two slides design centerless grinder is suitable for long bar outer diameter grinding application.

The advantages include the work rest fixed in the machine which enable better grinding accuracies for its stability.

FAIR FRIEND ENTERPRISE CO., LTD.

Product Description :

1. Improve tools life and cutting efficiency, especially ideal for particular process requirements of brittle or hard、 high-temperature superalloy and composite materials.

2. Increased precision and quality of the workpiece to achieve excellent cutting results. (smooth edge)

3. Perfected ultrasonic control technology for easy selection, automatic frequency, and power adjustment.

4. The strong chipping of chassis concentrates the chips into the path as ensures high efficiency.

5. Anti-scale cover + KEVLAR armor material, used in glasses, ceramics super hard metal processing which can preventing dust protection system effectively.。

HYDEX MACHINERY INDUSTRIAL CO., LTD.

Product Description :

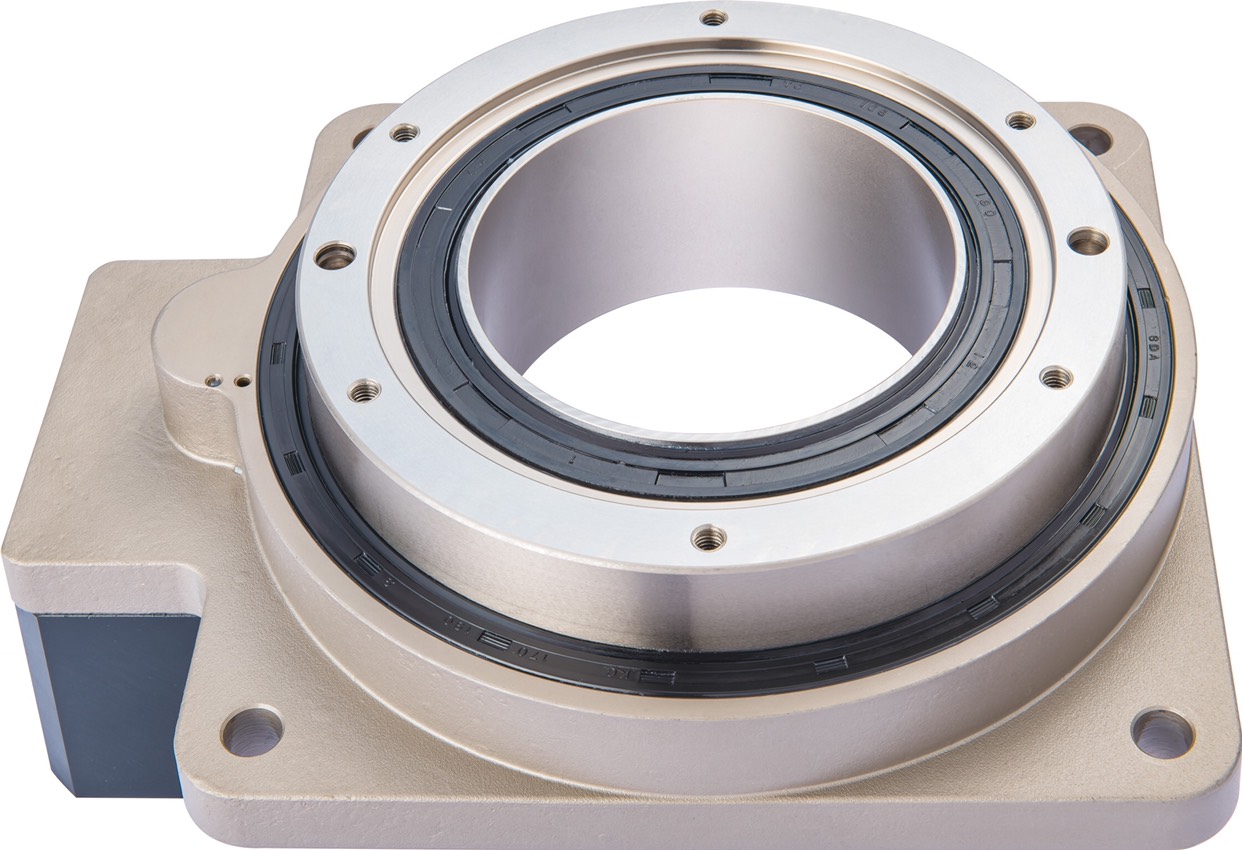

The hollow rotating platform is a brand-new kind of rotating load device. Incorporating high transmission eciency, high precision, high rigidity, and highcost performance, it combines the advantages of the servo motor, cam divider andDDmotor, obtaining a balance between these three products.

Compared with other similar transmission and location products, it not only can meet the point of ‘direct load to carrying capacity’, which is not achieved by the servo motor, but can also make up for the deciency that the divider cannot achieve at any angle location, namely, ‘achieving the location of any angle, and also compares favorably with the DD motor in precision. Furthermore, the cost is considerably less than that of the DD motor. Used together with the servo motor, it can completely meet your requirements from periphery positioning control.