Theme

Digital Transformation

Green Transformation

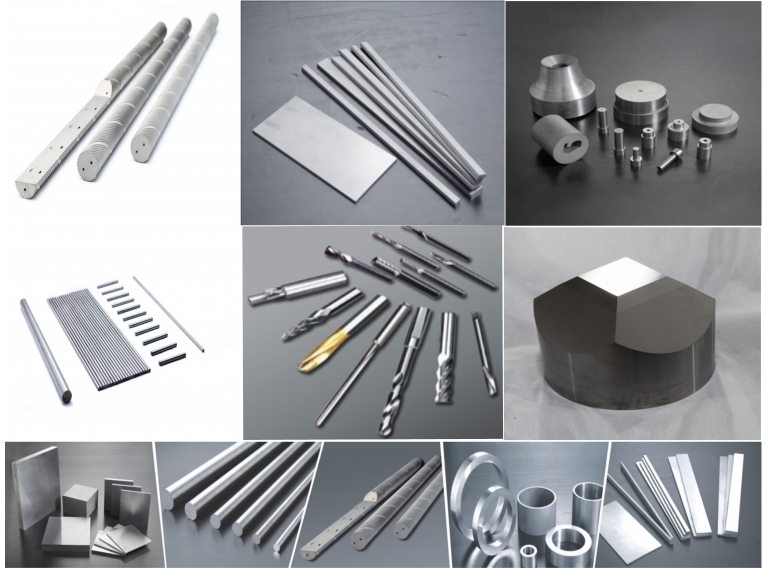

WIN-HIGH CO., LTD.

Product Description :

牌號: 適用加工材料:<br />

<br />

MD10 厚度小於0.2毫米的銅、鋁等薄片<br />

<br />

MD15 銅、鋁、不銹鋼等薄片<br />

<br />

MD20 通用性強,銅、鋁等薄片<br />

<br />

MD35A Q195 、SPCC等冷軋板<br />

<br />

MD36 EI 片、SPCC板等<br />

<br />

MD40A Q195 、SPCC等冷軋板<br />

<br />

MD45A 矽鋼片,冷軋板<br />

<br />

MD55 矽鋼片,上下沖頭<br />

<br />

ST05B 耐磨性好,模腔形狀簡單的模具。<br />

<br />

ST15B 通用性強,軟磁材料,鐵、銅基粉末模具。<br />

.<br />

ST10F 超細晶粒,適合硬磁材料成形模具。<br />

<br />

MD45A 適合型腔複雜的模具。<br />

<br />

MD50A 適合高負荷且型腔很複雜的模具。<br />

<br />

ST10B 綜合性能好,加工實木、密度板、刨花板及灰口鑄鐵、有色金屬等材料。<br />

<br />

ST10C 通用性強,加工實木、密度板、灰口鑄鐵、有色金屬等材料。<br />

<br />

ST03F 超細晶粒,抗腐蝕性能好、高耐磨,適用於有腐蝕介質的竹木刀具及製動材料的切削刀具。<br />

<br />

ST05F 超細晶粒,高硬度、高耐磨,適用於竹木刀具。<br />

<br />

ST10F 超細晶粒,適合製作形狀簡單的木工刀具和加工銅鋁合金、PCB、玻纖強化材料、制動材料、 <br />

石墨。<br />

<br />

ST11F 超細晶粒,適合加工硬木、密度板、刨花板等木工,竹木材料及加工鋁合金、淬硬鋼、冷硬鑄 <br />

鐵、制動材料。<br />

<br />

ST12F 超超細晶粒,適合加工刨花板, 不銹鋼、高淬硬鋼(硬度>HRC60)、玻纖強化材料,尤其適 <br />

合金屬的高速切削和乾切削。<br />

<br />

ST15F 超細晶粒,適合加工硬木、密度板、刨花板等木工材料及纖維強化材料。<br />

<br />

ST20F 通用性強,主要適用於灰口鑄鐵、冷硬鑄鐵、合金鋼等。<br />

<br />

ST25F 高溫合金、不銹鋼、鈦合金、淬硬鋼、絲錐。<br />

<br />

MD46A 耐磨性要求高,縮徑、單次變形量小的模具。<br />

<br />

MD50A 加工不銹鋼以及單次變形量不大的模具。<br />

<br />

MD60A 直桿,螺絲,螺帽上模等。<br />

<br />

MD62A 工作負荷較大的沉頭模具。<br />

<br />

MD65A 工作負荷較大的直桿模具。<br />

<br />

MD70A 螺帽下模、工作負荷大的模具<br />

ST06F 直徑小於1.5mm的鋼絲、鎢絲、鉬絲等硬材高速拉絲拉拔和表面光潔度要求很高的有色金屬線 <br />

材的拉製。耐腐蝕性強,在酸性潤滑拉伸時更為優越。<br />

<br />

ST19F 直徑在1.5mm~15mm範圍內的鋼絲、鎢絲、鉬絲等硬材高速拉絲拉拔和表面光潔度要求高的 <br />

有色金屬管(線)材的拉製。<br />

<br />

ST10UF 700系鋁、PCB、銅鋁合<br />

<br />

ST25EF 不銹鋼、模具鋼、高溫合金

LEADWELL CNC MACHINES MFG., CORP.

Product Description :

The 5 axes simultaneous processing, can reduce the times of workpiece unloading and the requirement of the jigs, shorten the processing time and improve performance. C-axis table using the DD motor provides high torque and rigidity and can solve the traditional worm gear backlash and worn problems. High torque and efficiency of the spindle with a complete high-rigidity structure applied results in roughing to finishing can be completed on the same machine, suitable for machining hard materials and non-ferrous materials processing.

X-axis travel: 1300mm

Y-axis travel: 610mm

Z-axis travel: 610/750mm

Table size: 1480x610mm

Max. table load: 1600kg

Spindle speed: 12000rpm

C-axis speed: 800rpm

X/Y/Z-axis rapid traverse: 36/36/30 m/min

Tool storage capacity: 30T

HARVEST FUN INTERNATIONAL CORPORATION LIMITED

Product Description :

CE EN ISO 20345: 2022 S7S SR FO HRO

CNS 20345: 2015 S3 SRC HRO WR

Metal Free Safety Toe∣Height 19cm∣Weight(EUR41)580g|Shoe size 36-48

1.Meets WR waterproof standard

2.Made of durable and tear-resistant ultra-fiber PU synthetic leather

3.StitchDown technique ensures that the outsole never comes off

4.GRP (glass fiber-reinforced plastic)Toe cap which is 50% lighter and can pass through metal detection gates

5.ExpLayer Anti-penetration is 55% lighter than metal, tough yet flexible

6.Foam material shock-absorbing and antibacterial insole provides good support for long standing

BUFFALO MACHINERY CO., LTD.

Product Description :

AXILE’s automated G6 Robotic Pallet Changer (RPC) solution features a 2-axis robot that keeps machines supplied with workpieces 24/7 from the back side of the machine. Part processing continues simultaneously within the machining center while operators deal with workpieces at the holding area at the back, significantly raising production efficiency to boost throughput.

The G6 RPC solution caters to diverse production requirements, with multiple options available based on workpiece specifications:

8 pallets (workpiece max. size 500 x 305 mm; max. weight 220 kg)

10 pallets (workpiece max. size 400 x 305 mm; max. weight 220 kg)

16 pallets (workpiece max. size 230 X 305 mm; max. weight 98 kg)

20 pallets (workpiece max. size 160 x 250 mm; max. weight 30 kg)

With AXILE’s digitalized intelligent automation solutions, manufacturers can eliminate production bottlenecks and ramp up production.

HO CHEN MACHINERY & ELECTRIC IND. CO., LTD.

Product Description :

X axis travel:

Single movement: 2550 mm (100") inch

Dual movement: 1275 mm (50") inch

YZ axes travel: 850x600 mm (33"x24") inch

※Y axis can be increased to 1300 mm(51") (Option)

※Z axis can be increased to 1000 mm(39") (Option)

Work table: 3100x1600 mm (122"x63") inch

Max. Workpiece: 4100x2050x1250 mm (161"x81"x49") inch

Max. Workpiece weight: 22000 kg

Max. electrode weight: 500 kg

Machine net weight: 29410 kg

Oil level: 110-1000mm (4"-39") inch

Occupy size(LxWxH): 6480x6600x4600 mm (255"x260"x181") inch

Work Table to platen:

600mm Z travel machine: 1138-1738mm (45"-68")

1000mm Z travel machine: 740-1740mm (29"-69")

Filter: 4

Paper filter:8

Capacity:11300 Liters

Machine Features

> Windows CE controller

> A dialog window with picture description.

> Special repaired frames to quicken the maintenance speed.

> Close-loop design of digital feedback on three axes of the machine significantly increases positioning precision and ORBIT-CUT machining accuracy and efficiency.

> Simple operation interface.

> Common function keys are located on the operational panel for direct use.

> Hot key setting.

> ATC (automatic tool change) and C-axis 360° index can be installed; the process of coarse machining to ultra-fine machining can be completed at one time.

> Dialogue diagram provides various hole-expanding modes such as quick search of edge, centers and datum marks.

> Rich color graphic (the same resolution as a PC screen).

> Automatic multi-step machining (coarse, medium coarse, medium fine, fine, superfine)—up to 10 steps.

> Unlimited number of machining conditions can be saved as machining archives. Each set of machining conditions can be edited, modified or stored. They are easy to edit and easy to find.

> Automatic origin search and multi-point coordinate memory capability.

> 1/2 design capability, ARC automatic discharge waveform detection and automatic adjustment.

> Automatic center position detection, automatic compensation, search of hole center and deepest point; fixed hole machining (cyclic mode, independent mode), which is suitable for different machining conditions; Radial, circular, square, linear (vector), coning, 45° hole-expanding machining.

> Three-axis beeline, two-axis arc, three-axis helix.

> Chinese/English versions interface, metric/British system switch and Z-axis quick up, quick down, slow up and slow down capability.

> Lateral machining, three axes, six directions (plane rotation).

> All alarms describe the source, date and exact time of problem occurrence.

> Optical scale is applied for close-loop position control, enabling extreme position for machining.

> Automatic editing—settings can be done according to type of material, work piece size, machining depth, one side die clearance, final current and rate of electrode wear.

> CNC models possess conventional capability of consistent level of energy discharge, achieving stable and rapid machining and smooth high quality on machining surface while the rate of electrode wear is still low.

> Monitor page indicates machining path and orbital pattern in use.