Theme

Digital Transformation

Green Transformation

KAO MING MACHINERY INDUSTRIAL CO., LTD.

Product Description :

1. 機器結構為工作台固定,橫樑前後移動之高架式設計。<br />

<br />

2. 高剛性結構最適合超長超大工件之加工。加工精度極穩定。<br />

<br />

3. 超大三軸行程: X軸: 6.5~14.5米<br />

Y軸: 2.5/ 3.1/ 3.7米<br />

Z軸: 1.2米<br />

4. 整體佔地面積比一般機台節省25%以上<br />

<br />

5. 固定式工作台最大荷重能力高達10,000 kgf/m2。<br />

<br />

6. 採用FEA有限元素分析法,模擬機器變形與振動模式,以獲得最強的結構與最佳化設計。<br />

<br />

7. X,Y軸安裝機械式預壓齒輪條驅動減速機構,能獲得幾乎零背隙的線性精度。<br />

<br />

8. X,Y 軸方形硬軌都採用階梯式設計。使橫樑及主軸頭在重切削及快速進幾下能保有穩定的切削性能。<br />

<br />

9. 自動臥式換刀機構整合於原有立式換刀系統;簡化設計,具獨創性。標準頭配備立式頭及臥式頭之2個位置AAC自動執行換頭動作。更多附加頭需求時,可擴充頭庫至3-5個位置。<br />

QUASER MACHINE TOOLS, INC.

Product Description :

This single unit machine features high rigidity, accuracy, and efficiency and offers a high ease of operation with a relatively compact footprint.

The Symmetrical design ensures the rigidity of the machine tool, which results in better damping performance and lower thermal displacement.

The modular design allows for expandable multi-pallet configurations.

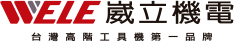

WELE MECHATRONIC CO., LTD.

Product Description :

1.立車主軸轉盤以進口交叉滾子軸承設計,確保重負荷的能力及長期的精度壽命。

2. Z軸226 mm方型滑枕搪孔軸採硬軌配Turcite B結構,VTC1612-CW標準行程900mm。

3.底座、立柱、橫樑、工作台等大型鑄件依製造需要,經由最新的3D設計,剛性最佳化,並以

多年經驗訂定有效的退火程序以消除殘餘應力,多年實際應用經驗,確實能達成有效的長期精

度保持性。

4.X、Z軸標準配備採用「雙編碼器」的「雙」半閉環回饋系統,經濟有效的提高各軸的定位精度。

(X、Z軸可選購德國Heidenhain或西班牙FAGOR光學尺)。

5.VTC-CW標準刀庫容量為16P(16儲位),車刀型式及分配數目可依客戶要求處理。

6.主軸箱等關鍵零件係利用自有的「大型臥式鏜孔機」及「大型高精度三次元量測儀(三座標量床)」

確實達成應有的加工精度,確保優良的組裝基礎。

7.承襲歐美先進工具機廠的標準,以嚴格維護的「1.2米x1.2米」高精密度的方形標準平板做為精密

精度的基礎,對各項關鍵零件進行精密鏟花(刮研),使機器的各處結合面和滑動面均能達到正確的

幾何精度,確保機器應有的精度和壽命。

8.搭配高規格的Fanuc數控系統,標準功能包含:15吋彩色液晶螢幕、Fanuc全鍵式操作面板、

2MB記憶容量、Ethernet網路接口、Flash記憶卡插口、剛性攻牙及各種特殊補間(插補)等多項

高規格功能,能經濟有效的滿足各種使用需求。

9.採用的各項配套零組件均經過長期使用驗證,可確保機器長期運行的可靠性。

10.完整的品檢測試流程,搭配先進的自動光學直準儀、雷射干涉儀、球桿檢測儀、線上動平衡儀等

精密檢測儀器,確保出廠的機器都能達到設計的性能和應有的功能。

11.經驗豐富的研發團隊,突破老舊的包袱,協助客戶達成各種特殊需求。

12.兼具經驗和熱誠的服務團隊和完整的服務體系,可以及時有效的讓用戶的機器長保最佳使用狀態。

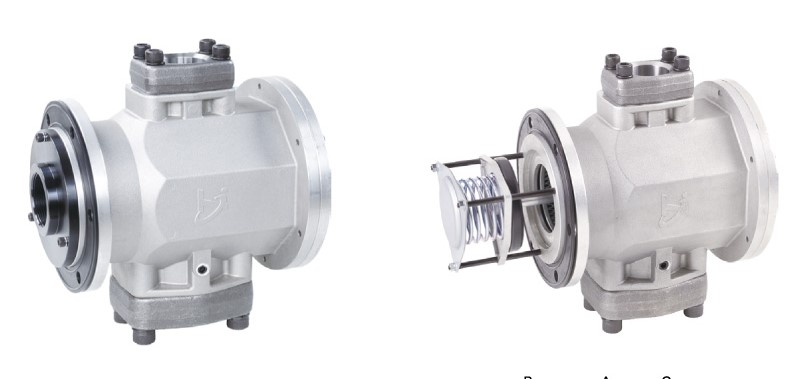

Go power machinery CO.LTD

Product Description :

Gutian Cam NC Rotary Table internally adopts cam roller transmission mechanism.

There is backlash-free rolling drive between cam and needle bearings pre-load, no sliding

friction or backlash. Its positive reverse motion has high repeatability accuracy, without theneed for periodic calibration and adjustments. This product is featured with high rigidity,heavy load, high efficiency, and its accuracy is not affected by rising temperature.

CHUAN TAI HYDRAULIC MACHINERY CO., LTD.

Product Description :

In order to solve the problem of difficult cleaning, the market developed so-called box-shaped filters, but still can not completely solve

1 takes up too much space

2 Multiple pump combination systems must be configured one-to-one, resulting in too many connectorsProne to oil leakage

In order to solve the above problems, the company has developed a pair of two-box external magnetic flange filters to reduce space and prevent oil leakage problems, reduce assembly time and parts costs

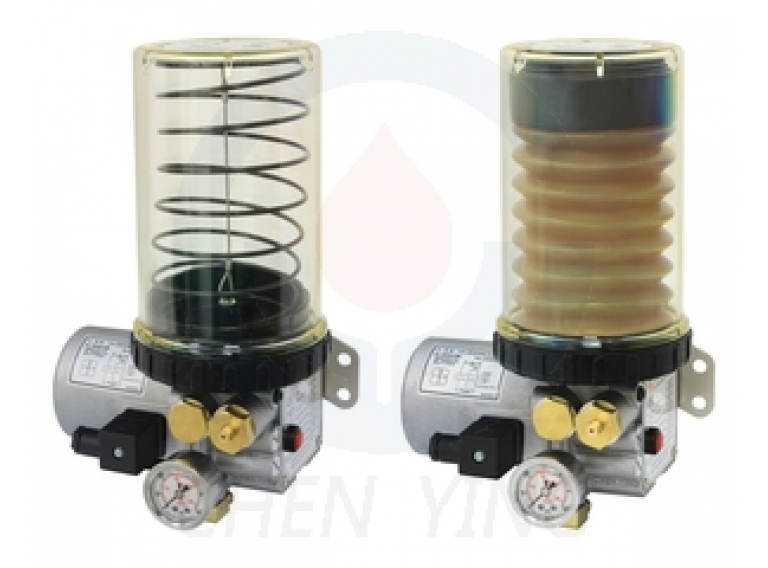

CHANGHUA CHEN YING OIL MACHINE CO., LTD.

Product Description :

1. KGC and KGCP types are suitable for grease NLGI grades 000, 00 and 0.

2. Recommend using a grease gun for filling with lubricant from grease inlet. It can avoid air or impurities dropping into the reservoir.

3. KGC and KGCP types are controlled by PLC (Programmable Logic Controller). It can work with CV type Progressive Feeders which can supply fixed volume of grease. CV type Progressive Feeders can assure each of lubrication point has equal amount of grease.

4. Pressure switch can be added on request for checking if the piping works normally. The standard setting is at 60 bars and the standard specification is NC (Normally Closed) contact, which means if the pressure doesn't reach the default setting, it sends continuous signals. NO (Normally Open) contact is available on request.

5. Magnet Level Switch is also an optional accessory that can be added upon request. It sends continuous signal automatically when the grease level is lower than the minimum level.

6. For the first time use, slightly press the Feed button (F button) to feed grease immediately. F button can be used as manually grease feeding for no more than 3 minutes.

7. AC110V and AC220V motors have thermal controls. When the motor temperature reaches 100℃, the sensor will be on to stop the motor continue running about 5 minutes.

8. It has a pressure gauge that the operator can check the pressure easily.

9. It can be used for the machines requiring strictly rationing grease flow. It usually works with rubber or plastic machines, press machines, machine centers, woodworking machines, etc.