Theme

Digital Transformation

Green Transformation

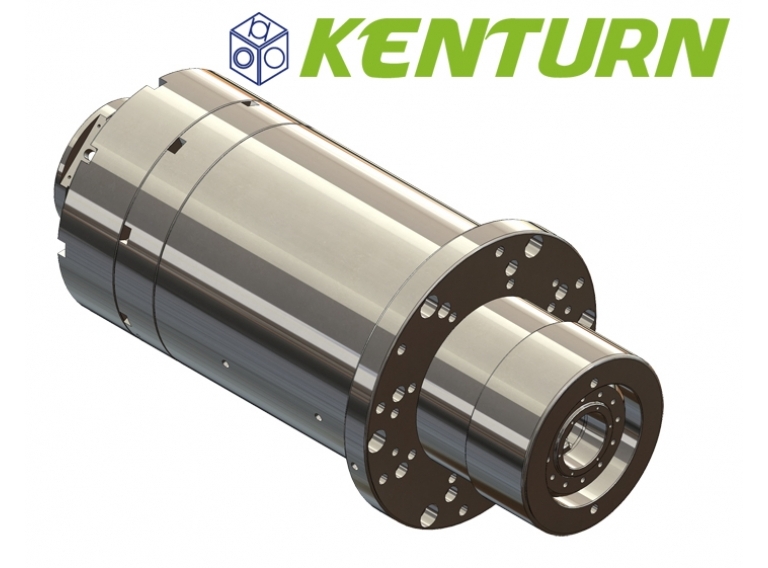

KENTURN NANO. TEC. CO., LTD.

Product Description :

Our own manufacturing spindle can fulfill the coolant of axis also inhibit the heat and thermal deformation by using the Germany original OTT HSK-A63 drawbar system. Besides, the oil-air lubricating bearings can stand long-term cutting operation. The spindle, motor power is up to 25KW, speed 18000 RPM, using dualdrive chunk, can be used in vertical machining centers and medium gantry machine.

FALCON MACHINE TOOLS CO., LTD.

Product Description :

Improved grinding performance, precision and stability

Chevalier's FSG-20/24ADIV Series of surface grinders now includes four new machine sizes, along with several newly designed features: a traveling column structure to further reduce vibration and achieve higher accuracy; a spindle that can withstand heavy load grinding; and a double-V guideway for smooth, stable longitudinal movements. Fully supported worktable design. Maximum table speed: 30 m/min (98.4 fpm), increases processing efficiency. Integrated machine-body temperature control system greatly improves accuracy and stability.

These four larger sizes, along with the entire FSG-20/24ADIV Series, offer several design features to shorten processing and non-processing preparation while delivering high-precision workpieces: iSurface control, variable speed spindle, constant surface speed, smart grinding path and in-machine manual dynamic balancing.

The driving forces behind this series pave the way to smart manufacturing by meeting the current grinding demands and standards required by the automotive, electric vehicle, mining, aerospace and job shop industries.

ADLEE POWERTRONIC CO., LTD.

Product Description :

Product applications:

Surface grinding machine、Internal & External grinder、CNC lathe machine、CNC milling machine, etc.

Adlee manufactures V3 class of AC spindle motor. The motion of AC induction motor makes great performance and this special design for milling machine spindle.

1. V3 class spindle motor.

2. 3 phase AC induction motor has extra low vibration performance.

3. Efficiency conforms to IEC 60034-30 IE3 standards IEC motor.

4. IEC motor specifically designs for grinding machine and low vibration applications.

5. Power range is from 1HP to 20HP.

OCEAN TECHNOLOGIES CO., LTD.

Product Description :

CNC Drilling EDM —RIVER 1000

Ocean Technologies' state-of-the-art product is designed with Five-axis tool center point (TCP) control

(X, Y, Z, A, B five-axis synchronization) drilling on irregular shared workpiece or special alloy steel parts.

The software can be break through and diffuser Shape Technologies to meet aerospace industry.

GREEN ECO PRO CO. LTD.

Product Description :

Precision filtration system

Due to different grinding and processing materials, the particle size, quality, and hardness of the materials to be filtered will also vary. For this reason, our filtering equipment was designed, which can be used for quartz, silicon carbide, semiconductor grinding, electrical discharge machining, or high precision requirements and can effectively intercept fine impurities.

Continuous/batch processing

Customized tungsten steel stirring motor

Filter material saturation alarm

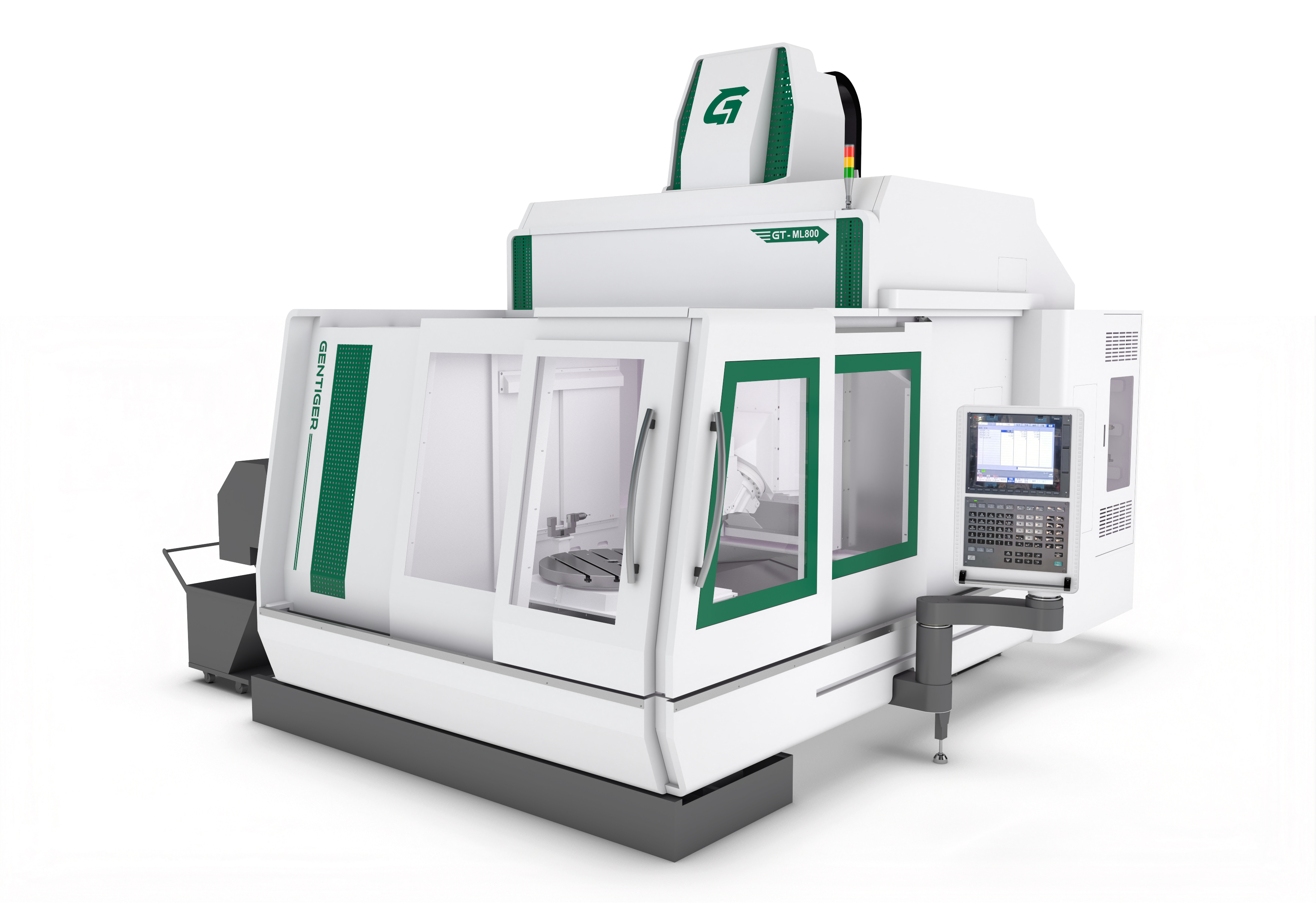

GENTIGER MACHINERY INDUSTRIAL CO., LTD.

Product Description :

• Closed-type double-column structure, it increases structure dramatically increases the structural rigidity of the machine and maintains extraordinary stability at all times.

• Roller-type linear guideway on three axes, it achieves high loading resistance, high rigidity, long service life, low thermal growth, and low noise.

• Three linear guideways on the Y axis, it provides more stable support for the spindle head, which contributes to upgraded stability in machining.

• The 45° vertical horizontal swiveling head is applicable for both vertical and horizontal machining, increasing flexibility in machining applications.