Theme

Digital Transformation

Green Transformation

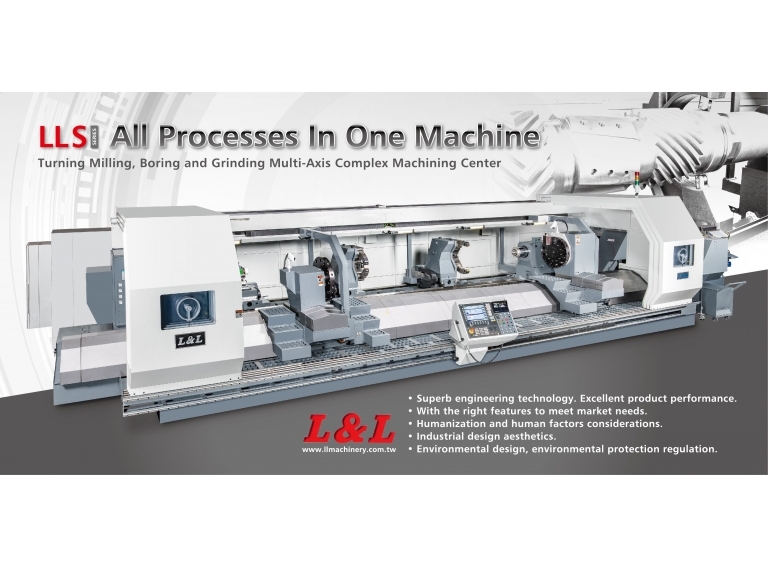

L & L MACHINERY INDUSTRY CO., LTD.

Product Description :

L&L LLS multi-axis composite cutting center machine, targeting the plastic rubber machinery industry, the application function exceeds customer demand:

a. Reduce the number of times of machining twice, reduce tool interference, and reduce work time by 50%.

b. Bed structure patent, one-piece casting, μ-level scraping process to ensure accuracy and stability.

c. Programmable tailstock, hydraulic center frame, independent chip removal device, programmable automatic door, high speed splash screen, full cover sheet metal design.

d. Full-cover design reduces the leakage of coolant, the design of the coolant collect plate for bed base, and the addition design of oil mist collector to reduce oil and gas pollution.

HAWE Hydraulik Singapore Pte. Ltd. Taiwan Branch

Product Description :

Compact hydraulic power packs are a type of hydraulic power pack. They arecharacterised by a highly compact design, since the motor shaft of the electric drive also acts as the pump shaft. Compact hydraulic power packs are designed to supply hydraulic circuits with hydraulic fluid.

The compact hydraulic power pack type INKA consists of the tank, the integrated motor and the radial piston pump or gear pump directly attached to the motor

shaft. The directly mounted electronic communication box with integrated realtime operating system allows the operating state to be recorded and visualised. The

measured values of the integrated multi-sensor (including the motor speed) can be passed on to the higher-level machine controls via standardised interfaces and processed there.

The consistently modular design of the type INKA means that different usage volumes and delivery flows can be realised quickly and easily from the modular

system. Compatible, ready-for-connection, complete solutions can be assembled easily using a wide range of connection blocks and the valve banks that can be combined with them.

Features and benefits

■ Prepared for condition monitoring with integrated sensors and communication box

■ Optimum efficiency through under-oil motor cooling, direct power transmission,and sophisticated heat dissipation

■ Suitable for nominal operating modes S2 (short period operation) and S3 (periodic intermittent operation)

■ Resource-saving due to small oil filling volume

Intended applications

■ Machine tools and material testing

■ Hydraulic tools

■ Handling systems

■ Presses and processing machines

ASMITH MANUFACTURING COMPANY

Product Description :

Dust-resistant, waterproof (IP66), resistance to heat and corrosion.

Patent: Pawl is fixed by 4 positioning points and the grooved shaft-bolt, easy for assembly and adjustment. Need only to slide the pawl through the shaft-groove to the correct position, more stable and accurate.

Left, right and top opening. The pawl moved forward and reversed vertically 3mm while the compression latch is opened and closed.

Used widely for door panel of general cabinet boxes.

Pawl can be easily positioned to accommodate the suitable compression.

In accordance with RoHS.

➤Material-body and lever: SUS304(stainless steel)-vibration ground and brushed finish in front.

➤Material-shaft, pawl and mounting bracket: SUS304(stainless steel).

Cartell Chemical Co., Ltd.

Product Description :

◆甲基瞬間膠:可應用於不同材質與間隙之黏接。特別是針對塑膠,橡膠、金屬彼此之間的接著。

◆乙基瞬間膠:對於乾燥、多孔性、低表面能材質或酸性表面等困難接著材料,或低濕度環境中,均可達到快速及有效接著的效果。

◆乙基瞬間膠 (抗震動/耐衝擊/強韌彈性):此系列產品是使用橡膠或酸酐增韌劑配方,用於吸收和分散施加在接著劑膠層上的衝擊和應力,從而形成更堅韌的接著,有助於提高固化後瞬間膠的剝離強度和抗衝擊性。

◆低氣味&低白化瞬間膠:極低氣味極低白霧,不影響接著劑的固化時間、接著強度或物理性能。

◆光固化瞬間膠:具有瞬間膠和光固化接著劑的所有優點,沒有任何侷限性。

◆醫療器材接著劑:通過 ISO10993-5標準的嚴格認證,確保了無論是手術工具、診斷設備還是其他醫療器材的生產過程中的高度生物相容性與安全性。

◆特殊應用瞬間膠:針對高溫、高濕等不良環境下之接著需求所研發產品。

PRECISION MOTION INDUSTRIES, INC.

Product Description :

Achieved the high-precision motions, lifting, rotaty, as well as quick grip motion in confined spaces.

Features

•High Positioning Accuracy

•Lightweight and Compact

•Simple Installation

•Support Bearing

•Smooth Motion and Lower Noise

Application

SCARA robot, Assembly robot, Automatic loader, and Machining center's, ATC equipment.

ASMITH MANUFACTURING COMPANY

Product Description :

★Handle: FRP has high stiffness and high loading. Load capacity 60 kgf, it is very light and an insulator to electronics. Users will not be frostbitten when the operating temperature is frozen.

Holder: The hole pitch can be adjustable within 18mm, easy to install. Waterproof (IP66). Working temperature is -20℃~150℃, resistance to acid, alkali, and greasiness.

Two ways for install: 1. Inner stationary type. 2. Outside stationary type.

In accordance with RoHS.

➤Material-Handle : Fibre-reinforced plastic(FRP), Black or Silver

➤Material-Holder : Polyamide(PA6-GF33), Black or Silver.

DKSH Taiwan Ltd.

Product Description :

The PC R series evaporators have a heating system based on a heat pump and operate under vacuum at 5kPa and around 30°C (86°F).

Heat exchange occurs within a conical jacket, and the boiling chamber inside part is cleaned by internal scrapers that continuously stir concentrate. This configuration is designed to produce a concentrate with a high final concentration and a distillate with low conductivity.

•From 0,1 to 2 m3/day – 0.02 to 0.37 US gpm of distillate

•Dramatic reduction of volumes and disposal costs

•Matter recovery

Extremely suitable when:

•the wastewater has a high initial content of dissolved or suspended solids

•the wastewater is already pre-concentrated

•the daily volumes are relatively small

•the distillate has to be of the highest quality

•the concentrate has to be recycled