Theme

Digital Transformation

Green Transformation

RENISHAW (TAIWAN) INC.

Product Description :

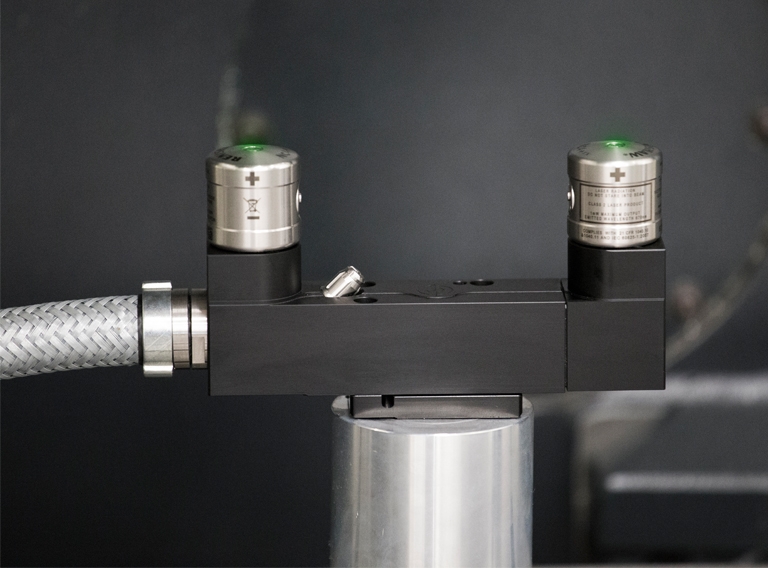

NC4 - 不是只有刀具設定!<br />

<br />

Renishaw 的 NC4 將更快速且更精確的刀具設定優勢附加在製程中且更容易理解。進行加工製程時,尺寸精度取決於變數,包括刀具尺寸偏差、刀具/刀把偏擺與刀具破損。<br />

<br />

Renishaw NC4 非接觸式刀具設定可以:<br />

<br />

• 補償加工製程中出現的誤差<br />

• 自動更新加工機控制器,以補償實際影響,例如刀具磨損<br />

• 於檢測出刀具破損時自動停止製程<br />

• 減少重工、製程妥協及廢品

SGCAM TECHNOLOGY CO., LTD.

Product Description :

主功能介紹:<br />

全中文畫面,易學、易懂、易用,為加工業最適合的加工軟體,操作軟體完全不用背指令。<br />

可由AutoCAD製圖畫出工件外形,再匯入DXF圖檔,轉換為CNC程式碼。<br />

參數式的加工資料設定,作CAM只需三個步驟:(1)選擇工法(2)指定加工參數(3)計算、轉出加工G碼。<br />

參數式的資料設定,圖形改變後,加工碼會自動隨之改變。<br />

智慧型功能:<br />

工法和加工的輪廓可直接複製修改,不必再重新指定。<br />

自動清角可自動清除前一把刀具,所留下來的角落殘料。<br />

鑽孔時依據孔徑大小,自動搜尋鑽孔的加工位置,不必每一孔都去點選指定。<br />

字型可自動截割輪廓外圍不用慢慢編修。<br />

支援單筆劃字型刻字。<br />

加工路徑最佳化,各加工路徑間依最短距離自動計算,且可指定各加工路徑間不提刀以縮短加工時間,達到最佳之加工效率。<br />

立體加工: 不必畫3D曲面圖形就可做出立體加工工法,簡單夾治具可自行製作。<br />

牽引面加工:可加工彎管、簡單的立體。<br />

規則面加工:規則斜面、四角錐面、圓錐面。<br />

旋轉面加工:圓球面、葫蘆形狀。<br />

Z軸投影加工:可在不等高的平面上作投影加工。

HO CHEN MACHINERY & ELECTRIC IND. CO., LTD.

Product Description :

XYZ axes travel: 600x400x400mm (23.62"x15.74"x15.74")

W axis travel: 450mm (17.71")

Work table: 650x450mm(25.59"x17.71")

Max. Workpiece: 900x500x300mm(35.43"x19.68"x11.81")

Max. Workpiece weight: 700kg

Distance from table to guide plate:25~425mm(0.98"x16.73")

Machine dimensions: 1580x1250x2740(62.2"x49.21"x107.87")

Machine net weight: 1200kg

Electrode diameter: 0.2~3.0mm

Dielectric fluid: pure water ( dielectric oil for 0.2mm or below)

Filtration: Paper filter

Controlling axes XYZW

Monitor: 15” LCD screen

Input/output unit: LAN/USB

Min. Setting Unit: 0.001mm

Min. Moving Unit: 0.001mm

Graphical display: 2D

Machine Features

1. This system utilizes Windows CE controller.

2. Able to store data through USB and internet.

3. Dialogue window, along with picture description functions.

4. Touchscreen type interface.

5. Special repaired frames to quicken the maintenance speed.

6. Close-Loop design of digital feedback on three axis of the machine, significantly increases positioning accuracy.

7. Possessing good and simple operation interfaces

Common function keys are located on the operation panel for direct use, hot key function on screen for quick access.

8. ATC (automatic tool changer) and AGC(automatic guide chnger) can be installed

9. Unlimited number of machining conditions can be saved as machining archives. Each set of machining conditions can be edited, modified or stored. They are easy to edit and easy to search.

10. Automatic origin search and multi-point coordinate memory capability.

11. Chinese/English versions, Metric/British system switch and quick up, quick down, and slow up and slow down capabilities, resolution can reach 1um.

12. All alarms describe the source, data and exact time of problem occurrence.

13. Able to proceed standard GM code and extra GM code

14. Able to proceed DXF file transfer to position coordinate function

15. AB axis rotate table can be installed

16. Position simulation and work route can be displayed

17. During discharge change new electrode can automatically compensate depth

18. Backlash point automatic compensate function

19. Able to do single hole drilling, multiple hole drilling and multi thickness drilling

20. Blindhole drilling function, any depth can be set

21. Initial current can set to reduced value, which can prevent workjob surface damage

22. Initial polarity reverse function, can prevent uneven electrode caused efficiency decrease

23. Six axis linear interoperate accelerate speed movement

24. Input, output, various of machine status real time display system

25. Discharge program and parameter conversion function

Accessories

《 Standard Accessories for High-speed Drilling CNC EDM 》

Tool Box*1

Brass Electrode 1.0mm*10

Electrode Guide 1.0mm*1

Standard Chuck*1

Foot Pads*1 set

Filter*1

Rubber Seal*10

Halogen Work Lamp*1

Flushing Unit*1 set

《 Optional Accessories for High-speed Drilling CNC EDM 》

ATC

Electrode Guide(Other diameters)

Brass Electrode(Other diameters)

ER Type Chuck for electrodes up to 6mm

Submerged Work Tank

75Amp Power upgrade

Filtration System with Resin Bottle

A,B Axes

Automatic guide changer 3/6

JAR HON MACHINERY CO., LTD.

Product Description :

1.Both cutting TAP and forming TAP are suitable.

2.Fully automatic machine so a person can operate many machines.

3.Gear-pitch type auto. tapping will get a precise & accurate thread for finished workpiece.

4.It can option to add inverter or use servo motor to control the spindle speed.

4. Especially suitable for light workpiece.

RUN ACE CO., LTD.

Product Description :

Gambini Meccanica in Italy specializes in the production of high-precision transmission gear rows, gears and screws. The main application areas of the products are industrial automation, aviation, grinding plants, steel plants,

Wood, stone, aluminum processing machines, textile industry machines, material handling equipment, trucks and hydraulic cranes, petrochemical plants, food processing machinery and agricultural machinery.

AUTOGRIP MACHINERY CO., LTD.

Product Description :

Pneumatic pressure status.

Support Front/Rear chuck configuration.

Abnormal pressure loss alarm.

Wireless signal transmission.

XIN GONG YANG MACHINERY CO., LTD.

Product Description :

◎Types: 12.5HP x 4P ;15HP x 4P

◎Designed for machine tools, including CNC heavy-duty double-column milling machines, dedicated machinery etc.

OSCAR E.D.M. COMPANY LTD.

Product Description :

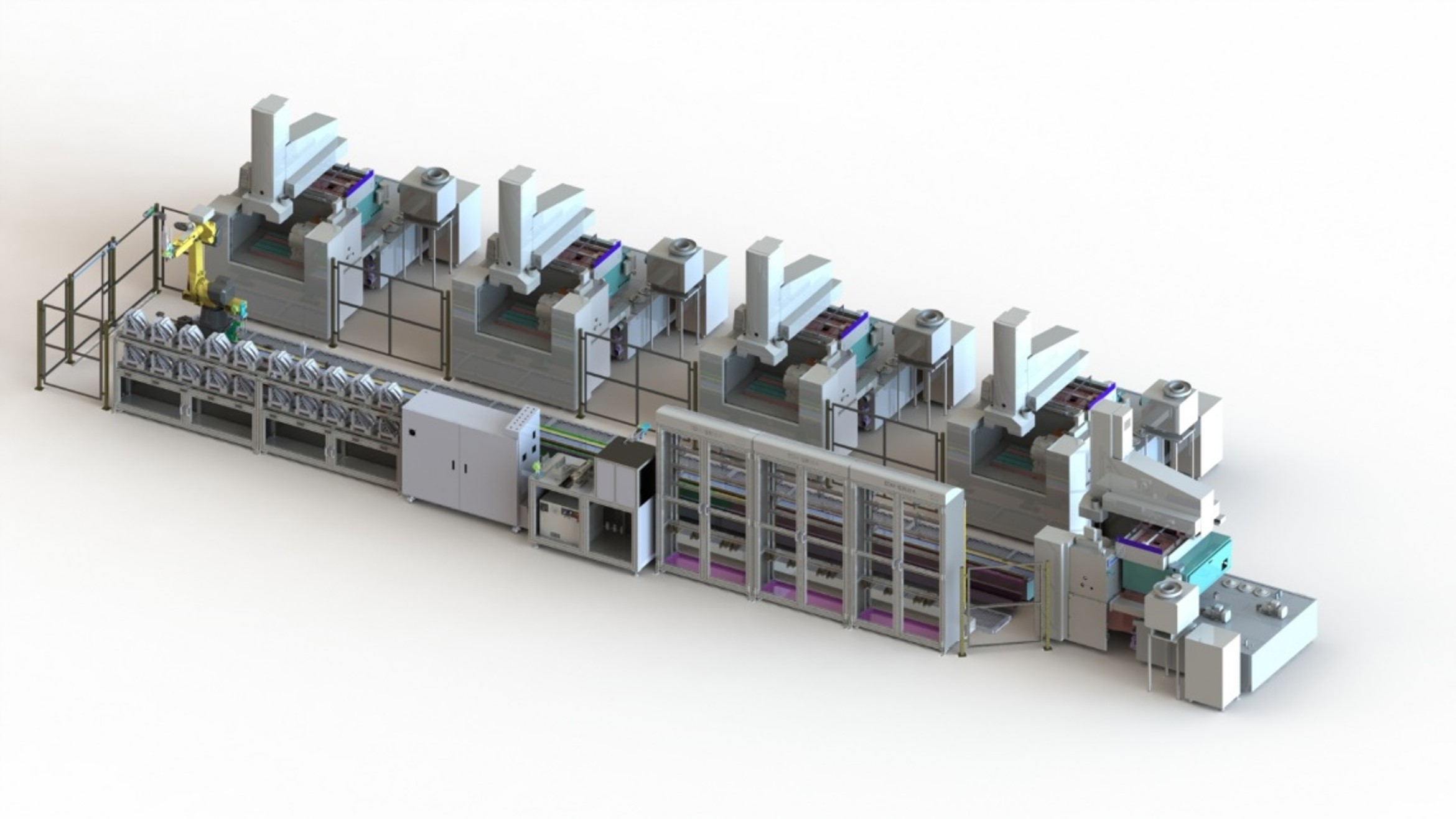

Quick Integration

EX/EXD Series electrical discharge

machine, capable of easy integrated with

MES system, online measurement,

storage system and etc via OPCUA, API.

Smart Production line

Actual application on automobile moulding industry in

Europe. EX series sinker EDM integrated with MES and

milling machine where perform the production just-intime

without any interruption. By increasing 30% of

overall equipment effectivenss (OEE), 2 EDM will then

bring out extra 3,000 hours working time per year